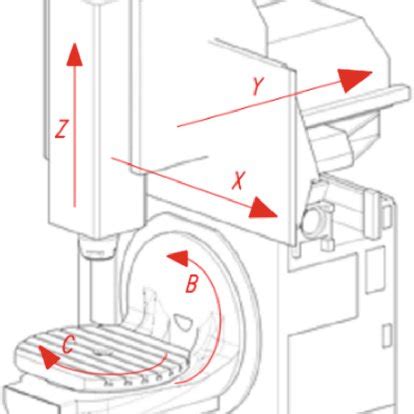

axes of a cnc machine Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface .

Best Metal Fabricators Victoria, BC - Altech Machining & Repairs, Modern Edge Design & Fabrication, Island Metal Craft, Crescent Moon Forge & Ironworks, Silver Fern Stainless, .

0 · cnc with rotary axis

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

Frequently made of wood, bentwood and metal, every cheese box was constructed with great care. You’ve searched high and low for the perfect cheese box — we have versions that date back to the 19th Century alongside those produced as recently as the 20th Century are available.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis .In this blog post, we will delve into the definition of CNC machine axes, explaining the significance of each axis and how they function in the machining process.

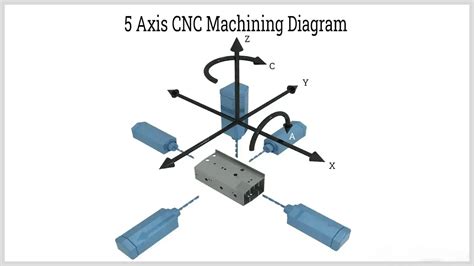

Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

This comprehensive guide explains the different axes on a CNC lathe, including the X, Y, and Z axes, and how they work together to control the movements of the cutting tool. Understanding these axes is essential for . Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface .

The number of axes in a CNC machine defines its degrees of freedom and, consequently, its complexity and versatility. While simpler CNC lathes typically operate with two primary axes (X and Z), more advanced . Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three .

There are 3 types of 4 axis machining: Indexing and continuous. Indexing rotates the A axis whilst the machine is not cutting the workpiece. Once the rotation is completed, the A axis brakes, and the cutting occurs. Continuous 4-axis .

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.In this blog post, we will delve into the definition of CNC machine axes, explaining the significance of each axis and how they function in the machining process. Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

flag holder metal bracket

cnc with rotary axis

This comprehensive guide explains the different axes on a CNC lathe, including the X, Y, and Z axes, and how they work together to control the movements of the cutting tool. Understanding these axes is essential for anyone operating a CNC lathe. Learn more here. Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.

The number of axes in a CNC machine defines its degrees of freedom and, consequently, its complexity and versatility. While simpler CNC lathes typically operate with two primary axes (X and Z), more advanced models can incorporate additional axes for . Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space. Coordinate systems are formed by the axes (X, Y & Z), planes, and an origin where the three axes meet.There are 3 types of 4 axis machining: Indexing and continuous. Indexing rotates the A axis whilst the machine is not cutting the workpiece. Once the rotation is completed, the A axis brakes, and the cutting occurs. Continuous 4-axis machining cuts material simultaneously with A axis rotation.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.In this blog post, we will delve into the definition of CNC machine axes, explaining the significance of each axis and how they function in the machining process. Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). This comprehensive guide explains the different axes on a CNC lathe, including the X, Y, and Z axes, and how they work together to control the movements of the cutting tool. Understanding these axes is essential for anyone operating a CNC lathe. Learn more here.

Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.

The number of axes in a CNC machine defines its degrees of freedom and, consequently, its complexity and versatility. While simpler CNC lathes typically operate with two primary axes (X and Z), more advanced models can incorporate additional axes for . Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space. Coordinate systems are formed by the axes (X, Y & Z), planes, and an origin where the three axes meet.

cnc machine axis locations diagram

flat galvanized sheet metal roofing

Add some vintage charm to your baking with these adorable cookie cutters! The .

axes of a cnc machine|axis identification in cnc machine