average demension of cnc machine Machine size and axis configurations play a crucial role in determining the workable . $12.30

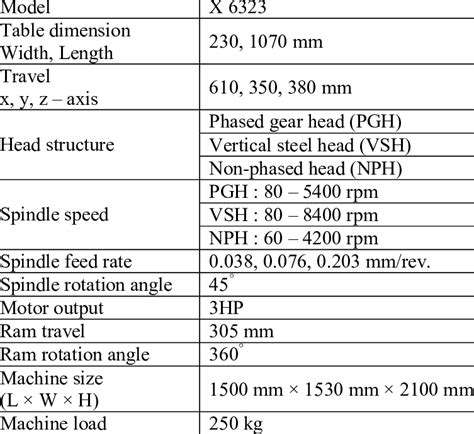

0 · specifications of cnc milling machine

1 · specification of cnc machine

2 · large scale cnc machine

3 · large cnc machine for wood

4 · large cnc cutting machine

5 · cnc machining size consideration

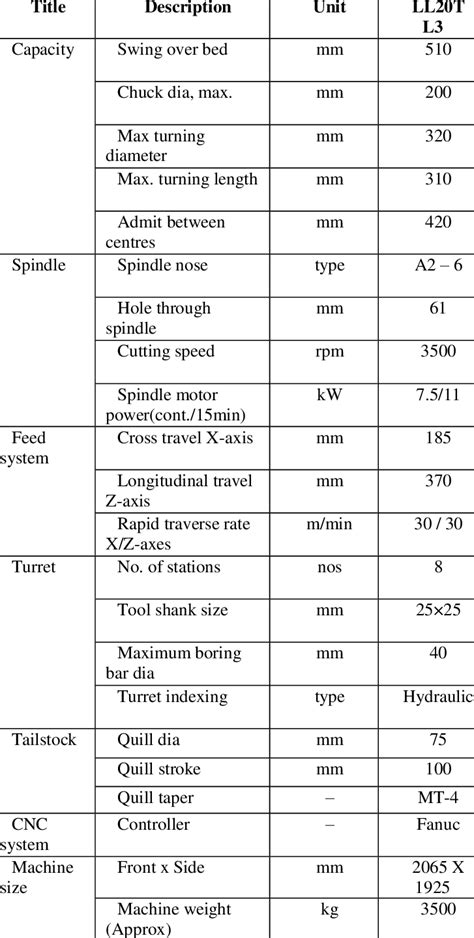

6 · cnc lathe machine specification

7 · best medium size cnc machine

Underground pull boxes are used when pulling, splicing, accessing, and storing cable, as well as providing a safe, durable and cost effective housing for system equipment. They can be used in electrical utilities, telecommunications, C&I, .

In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for selecting the right CNC machine for specific applications, optimizing productivity, and ensuring quality .In this blog post, we will delve into the various dimensions of a CNC milling .

Machine size and axis configurations play a crucial role in determining the workable .In this blog post, we will delve into the various dimensions of a CNC milling machine, including its size, working envelope, table size, and spindle movement. We will also explore the importance .Machine size and axis configurations play a crucial role in determining the workable area and flexibility of a CNC machine. We will delve into various configurations and the implications they .

General tolerances for CNC machining start at ±0.1 mm. Tighter tolerances, defined as smaller than the general standard, can be achieved with CNC machining, reaching up to ±0.01 mm. Specialized setups and additional . There's part size, feature sizes and power required, tool sizes, 10k spindle to 40k+ spindles. Figure out what types of parts you want to make and buy a machine to fit. Just know, . In this guide, I recommend best large-format CNC routers, mills, and lathes. I’ll review machines in a variety of different sizes, all the way from 4040 to 4×8 CNCs, and across every price range. 1. Best 4040 CNC: .

In this article, different types of CNC machines based on different classifications were discussed, providing explanations of their functions, applications, limitations, how they are used in manufacturing, and how to select the most suitable CNC . For parts manufactured on a lathe, the critical limiting dimensions are. .the maximum part diameter and the overall length of the part. Xometry supports parts up to 18" in diameter, but special considerations can be made . The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) .

CNC machines can range in price from just a thousand dollars to up to half a million, depending on their capabilities and features. In this guide, we’ll address some of the common questions about CNC, including: How much is a CNC .

specifications of cnc milling machine

In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for selecting the right CNC machine for specific applications, optimizing productivity, and .In this blog post, we will delve into the various dimensions of a CNC milling machine, including its size, working envelope, table size, and spindle movement. We will also explore the importance of these dimensions in achieving accurate and high-quality machining results.Machine size and axis configurations play a crucial role in determining the workable area and flexibility of a CNC machine. We will delve into various configurations and the implications they have on different applications. General tolerances for CNC machining start at ±0.1 mm. Tighter tolerances, defined as smaller than the general standard, can be achieved with CNC machining, reaching up to ±0.01 mm. Specialized setups and additional operations like reaming and grinding can allow for even tighter tolerances depending on the material and part geometry.

There's part size, feature sizes and power required, tool sizes, 10k spindle to 40k+ spindles. Figure out what types of parts you want to make and buy a machine to fit. Just know, if you buy a machine with 100" of travel, you'll get an RFQ for a 101" part. In this guide, I recommend best large-format CNC routers, mills, and lathes. I’ll review machines in a variety of different sizes, all the way from 4040 to 4×8 CNCs, and across every price range. 1. Best 4040 CNC: Sainsmart Genmitsu 4040 CNC Router.

In this article, different types of CNC machines based on different classifications were discussed, providing explanations of their functions, applications, limitations, how they are used in manufacturing, and how to select the most suitable CNC machine for your needs.

For parts manufactured on a lathe, the critical limiting dimensions are. .the maximum part diameter and the overall length of the part. Xometry supports parts up to 18" in diameter, but special considerations can be made for larger parts. The maximum overall length of parts that can be supported also depends on the part's maximum diameter. The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a truck onto their work area).CNC machines can range in price from just a thousand dollars to up to half a million, depending on their capabilities and features. In this guide, we’ll address some of the common questions about CNC, including: How much is a CNC machine? What factors affect the price of a CNC machine? How should you narrow down your search?In this comprehensive guide, we have explored the key dimensions of CNC machines and their significance in the manufacturing process. Understanding these dimensions is crucial for selecting the right CNC machine for specific applications, optimizing productivity, and .

In this blog post, we will delve into the various dimensions of a CNC milling machine, including its size, working envelope, table size, and spindle movement. We will also explore the importance of these dimensions in achieving accurate and high-quality machining results.Machine size and axis configurations play a crucial role in determining the workable area and flexibility of a CNC machine. We will delve into various configurations and the implications they have on different applications. General tolerances for CNC machining start at ±0.1 mm. Tighter tolerances, defined as smaller than the general standard, can be achieved with CNC machining, reaching up to ±0.01 mm. Specialized setups and additional operations like reaming and grinding can allow for even tighter tolerances depending on the material and part geometry. There's part size, feature sizes and power required, tool sizes, 10k spindle to 40k+ spindles. Figure out what types of parts you want to make and buy a machine to fit. Just know, if you buy a machine with 100" of travel, you'll get an RFQ for a 101" part.

In this guide, I recommend best large-format CNC routers, mills, and lathes. I’ll review machines in a variety of different sizes, all the way from 4040 to 4×8 CNCs, and across every price range. 1. Best 4040 CNC: Sainsmart Genmitsu 4040 CNC Router.In this article, different types of CNC machines based on different classifications were discussed, providing explanations of their functions, applications, limitations, how they are used in manufacturing, and how to select the most suitable CNC machine for your needs.

For parts manufactured on a lathe, the critical limiting dimensions are. .the maximum part diameter and the overall length of the part. Xometry supports parts up to 18" in diameter, but special considerations can be made for larger parts. The maximum overall length of parts that can be supported also depends on the part's maximum diameter. The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a truck onto their work area).

specification of cnc machine

$8.49

average demension of cnc machine|best medium size cnc machine