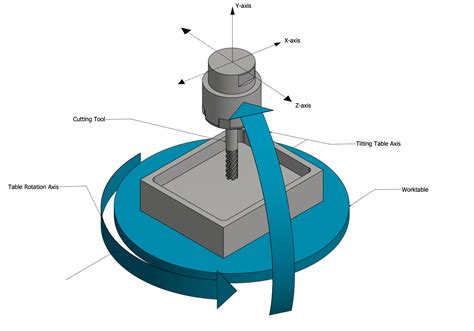

b axis in cnc machine 4-axis CNC machines typically have three linear axes (X, Y, Z) and one rotary axis (A or B). This additional axis allows the workpiece to rotate, enabling the creation of more complex shapes . Upon completion of the apprenticeship, individuals achieve journey-level status, ready to pursue a career as a professional sheet metal worker. Sheet metal finds applications in diverse industries such as construction, HVAC, industrial settings, architectural metalwork, and more.

0 · what is 5 axis machining

1 · cnc mill axis diagram

2 · cnc machine axis identification

3 · cnc axis explained

4 · 4 axis cnc milling machine

5 · 4 axis cnc mill

6 · 3 axis cnc milling machine

7 · 12 axis cnc machine

When it comes to selecting the ideal metal star for your home, consider the color, material, and type of paint or finish that best suits your design preferences and the overall character of your property.

what is 5 axis machining

A B-axis is a rotational axis in a CNC machine that allows the cutting tool to move in a circular motion around the workpiece. It is typically used in 5-axis machining to enable the machine to .The 4 th axis denotes the inclusion of an A axis (rotation around the X axis), and the 5 th axis denotes the B axis (rotation around the Y axis). The number of axes on a CNC machine determines the type of work it can do, the level of detail it . The B axis is capable of moving in an arbitrary five-axis plane rather than being restricted to the traditional live tool motions found on a Swiss machine, where a milling cutter .

4-axis CNC machines typically have three linear axes (X, Y, Z) and one rotary axis (A or B). This additional axis allows the workpiece to rotate, enabling the creation of more complex shapes .

cnc mill axis diagram

cnc machine axis identification

The B-axis provides rotational movement and allows for off-axis machining. This axis is particularly useful for creating complex shapes, such as angled holes or off-center features. In summary, CNC lathes typically have . Okuma offers a B-axis turning function for face turning operations on its Multus series machines. That, plus skiving capability for ID and OD splines as well as on-machine touch probing for measuring part features such as . In addition to the traditional three axes, 5-axis machining also uses two rotary axes: A-, B-, and/or C-. Using rotary axes means that a machine can move either the part or the cutting tool (spindle head) around one of the .

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

Multi-axis machining is a manufacturing process that utilizes multiple rotational axes to enhance the capabilities of conventional CNC machining. It is capable of creating . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.A B-axis is a rotational axis in a CNC machine that allows the cutting tool to move in a circular motion around the workpiece. It is typically used in 5-axis machining to enable the machine to access difficult-to-reach areas of the workpiece and perform complex cuts.

The 4 th axis denotes the inclusion of an A axis (rotation around the X axis), and the 5 th axis denotes the B axis (rotation around the Y axis). The number of axes on a CNC machine determines the type of work it can do, the level of detail it can cut, and the workpiece locations it can manipulate. The B axis is capable of moving in an arbitrary five-axis plane rather than being restricted to the traditional live tool motions found on a Swiss machine, where a milling cutter can be positioned axially or radially to either the diameter or the face of the part.

proper way to mig weld sheet metal

4-axis CNC machines typically have three linear axes (X, Y, Z) and one rotary axis (A or B). This additional axis allows the workpiece to rotate, enabling the creation of more complex shapes and features. 5-axis CNC machines have three linear axes (X, Y, Z) and two rotary axes (A/B and C).

The B-axis provides rotational movement and allows for off-axis machining. This axis is particularly useful for creating complex shapes, such as angled holes or off-center features. In summary, CNC lathes typically have two to four . Okuma offers a B-axis turning function for face turning operations on its Multus series machines. That, plus skiving capability for ID and OD splines as well as on-machine touch probing for measuring part features such as diameter, roundness and . In addition to the traditional three axes, 5-axis machining also uses two rotary axes: A-, B-, and/or C-. Using rotary axes means that a machine can move either the part or the cutting tool (spindle head) around one of the previously established linear axes. In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

Multi-axis machining is a manufacturing process that utilizes multiple rotational axes to enhance the capabilities of conventional CNC machining. It is capable of creating intricate parts with complex shapes, curved profiles, and undercuts. Multi-axis CNC machining is based on the Computer Numerical Control (CNC) technology. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

A B-axis is a rotational axis in a CNC machine that allows the cutting tool to move in a circular motion around the workpiece. It is typically used in 5-axis machining to enable the machine to access difficult-to-reach areas of the workpiece and perform complex cuts.The 4 th axis denotes the inclusion of an A axis (rotation around the X axis), and the 5 th axis denotes the B axis (rotation around the Y axis). The number of axes on a CNC machine determines the type of work it can do, the level of detail it can cut, and the workpiece locations it can manipulate. The B axis is capable of moving in an arbitrary five-axis plane rather than being restricted to the traditional live tool motions found on a Swiss machine, where a milling cutter can be positioned axially or radially to either the diameter or the face of the part.

4-axis CNC machines typically have three linear axes (X, Y, Z) and one rotary axis (A or B). This additional axis allows the workpiece to rotate, enabling the creation of more complex shapes and features. 5-axis CNC machines have three linear axes (X, Y, Z) and two rotary axes (A/B and C).

The B-axis provides rotational movement and allows for off-axis machining. This axis is particularly useful for creating complex shapes, such as angled holes or off-center features. In summary, CNC lathes typically have two to four .

Okuma offers a B-axis turning function for face turning operations on its Multus series machines. That, plus skiving capability for ID and OD splines as well as on-machine touch probing for measuring part features such as diameter, roundness and . In addition to the traditional three axes, 5-axis machining also uses two rotary axes: A-, B-, and/or C-. Using rotary axes means that a machine can move either the part or the cutting tool (spindle head) around one of the previously established linear axes.

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

cnc axis explained

Consider using a polyurethane adhesive for bonding metal to fabric, as it provides resilience and flexibility to withstand movement and stress. When bonding metal to fabric, it's crucial to use fabric-friendly bonding .

b axis in cnc machine|4 axis cnc mill