difference between cnc and vmc machine Understanding the differences between CNC, VMC, and HMC machines is crucial for selecting the right equipment for your manufacturing needs. Each machine type offers .

Traditional - Brackets + Shelving – Waddell

0 · work instruction for vmc machine

1 · vmc machine basic knowledge

2 · spindles in vmc

3 · jyoti vmc machine price list

4 · horizontal machining center vs vmc

5 · difference between vmc and hmc

6 · cnc vmc machine price

7 · bfw vmc machine price list

The 207-4301 from WAGO is a junction box designed for the 221 series splicing connectors. Accepts up to 60 conductors of 2, 3 or 5 conductor connectors A clear, structured arrangement that’s secured on one level

CNC (Computer Numerical Control) is a method of automating the control of machine tools through the use of computer programs. It involves the use of a computer to send digital instructions to the machine, which then moves the cutting tool to specific coordinates in order to produce a part or product. . See moreA VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other . See more

Understanding the distinctions between CNC and VMC machines is crucial for anyone involved in the manufacturing and machining industries. While both CNC and VMC technologies are .Key Differences Between CNC and VMC Machines: 1. Machine Configuration: One of the main differences between CNC and VMC machines lies in their configuration. CNC machines are .Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting . Understanding the differences between CNC, VMC, and HMC machines is crucial for selecting the right equipment for your manufacturing needs. Each machine type offers .

While CNC machines offer versatility and are suitable for various machining operations, VMC machines excel in high-speed milling with exceptional precision and surface finish. Choosing .

CNC machines are highly automated and require little human intervention, while VMC machines are manually operated and require more skill and attention from the operator. Additionally, CNC machining is typically used .

A VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other types of milling machines is that the spindle axis of a VMC is oriented vertically, rather than horizontally.Understanding the distinctions between CNC and VMC machines is crucial for anyone involved in the manufacturing and machining industries. While both CNC and VMC technologies are fundamental to modern precision machining, they serve different purposes and .Key Differences Between CNC and VMC Machines: 1. Machine Configuration: One of the main differences between CNC and VMC machines lies in their configuration. CNC machines are more generic and can be configured for both horizontal and vertical operations, whereas VMC machines are specifically designed for vertical machining. 2.

Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting applications, CNC finds a special place. 3. In CNC, a manual intervention is required for changing the tool. Understanding the differences between CNC, VMC, and HMC machines is crucial for selecting the right equipment for your manufacturing needs. Each machine type offers unique advantages, whether it’s the versatility of CNC machines, the precision of VMCs, or the productivity of HMCs.

While CNC machines offer versatility and are suitable for various machining operations, VMC machines excel in high-speed milling with exceptional precision and surface finish. Choosing between the two depends on the specific requirements of your application and the level of performance you seek.

CNC machines are highly automated and require little human intervention, while VMC machines are manually operated and require more skill and attention from the operator. Additionally, CNC machining is typically used for repetitive tasks, while VMC machining is usually used for more complex tasks.CNC is technology for machines and VMC is name of particular type machine. CNC technology encompasses the broader concept of computer control in machining, while VMC technology refers to a specific type of CNC machine with a vertical spindle orientation.

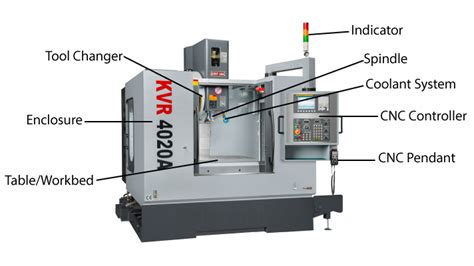

CNC machining center is a highly automated multi-functional machine tool that can be divided into horizontal and vertical machining centers, what’s the difference between them? Here is the introduction to what is CNC vertical machining center (VMC) and . VMC, or Vertical Machining Center, machines are a type of CNC machine commonly used for milling operations. Unlike traditional milling machines, VMC machines have a vertically oriented spindle, which enables them to perform complex machining tasks with ease.

A VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other types of milling machines is that the spindle axis of a VMC is oriented vertically, rather than horizontally.Understanding the distinctions between CNC and VMC machines is crucial for anyone involved in the manufacturing and machining industries. While both CNC and VMC technologies are fundamental to modern precision machining, they serve different purposes and .

work instruction for vmc machine

Key Differences Between CNC and VMC Machines: 1. Machine Configuration: One of the main differences between CNC and VMC machines lies in their configuration. CNC machines are more generic and can be configured for both horizontal and vertical operations, whereas VMC machines are specifically designed for vertical machining. 2.Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting applications, CNC finds a special place. 3. In CNC, a manual intervention is required for changing the tool. Understanding the differences between CNC, VMC, and HMC machines is crucial for selecting the right equipment for your manufacturing needs. Each machine type offers unique advantages, whether it’s the versatility of CNC machines, the precision of VMCs, or the productivity of HMCs.While CNC machines offer versatility and are suitable for various machining operations, VMC machines excel in high-speed milling with exceptional precision and surface finish. Choosing between the two depends on the specific requirements of your application and the level of performance you seek.

CNC machines are highly automated and require little human intervention, while VMC machines are manually operated and require more skill and attention from the operator. Additionally, CNC machining is typically used for repetitive tasks, while VMC machining is usually used for more complex tasks.CNC is technology for machines and VMC is name of particular type machine. CNC technology encompasses the broader concept of computer control in machining, while VMC technology refers to a specific type of CNC machine with a vertical spindle orientation.CNC machining center is a highly automated multi-functional machine tool that can be divided into horizontal and vertical machining centers, what’s the difference between them? Here is the introduction to what is CNC vertical machining center (VMC) and .

pacific sheet metal seattle

pacific sheet metal inc

INTERGREAT Metal Wall Storage Cabinet with Adjustable Shelf, Wall Mounted Tool Cabinets with Pegboard for Garage, Lockable 31” H Steel Medicine Cabinets with Doors, Home Office, Kitchen (32”W x 12”D)

difference between cnc and vmc machine|difference between vmc and hmc