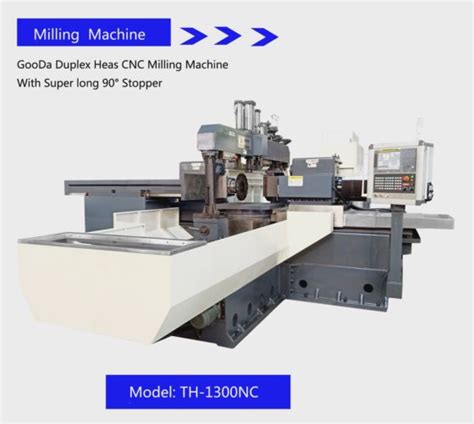

cnc cutting machine wiki These numerical control equipment includes machining centers, turning and milling centers, wire EDM equipment, thread cutting machines, etc. Cnc Machining processes workpieces in a . In this guide, I’ll compare all of the DIY CNC routers I’ve tested across their key strengths and limitations – like price, ease of use, speed, and power – so you can make a confident choice. 1. Sainsmart Genmitsu 3018 .

0 · types of cnc machines and their applications

1 · high end cnc machine tools

2 · cnc machines offers up website

3 · cnc machine for steel cutting

4 · cnc machine for plastic cutting

5 · cnc machine for cutting metal

6 · cnc cutting machine near me

7 · all types of cnc machines

We manufacturer CNC woodworking machines built in the USA with all-steel frames that come fully assembled and pre-tested. We provide the industry’s best customer service and training.

In CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, sometimes resulting in bending or breakage of cutting tools, accessory clamps, vises, and fixtures, or causing damage to the machine itself by bending guide rails, breaking drive screws, or causing structural components to crack or deform under strain. A mild crash may not damage the machine or tools but may damage the part being machined so t.

CNC cutting consists of two parts: the numerical control system and the mechanical structure. Compared with traditional manual and semi-automatic cutting, CNC .

types of cnc machines and their applications

high end cnc machine tools

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .These numerical control equipment includes machining centers, turning and milling centers, wire EDM equipment, thread cutting machines, etc. Cnc Machining processes workpieces in a .CNC lathes are one of the most widely used CNC machine tools. It is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disc parts, inner and outer conical surfaces with .

What Is CNC cutting? It is an exponentially controlled flame, plasma, laser and water jet cutting machine. It performs full-time, automatic, efficient, high-quality, and high-utilization CNC cutting according to the optimized nesting cutting . Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away .A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams.In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.

CNC cutting consists of two parts: the numerical control system and the mechanical structure. Compared with traditional manual and semi-automatic cutting, CNC cutting can effectively control and improve cutting quality and cutting efficiency through the cutting technology, cutting process and automatic control technology provided by the .The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .These numerical control equipment includes machining centers, turning and milling centers, wire EDM equipment, thread cutting machines, etc. Cnc Machining processes workpieces in a continuous manner, which is suitable for large-volume, complex-shaped parts.CNC lathes are one of the most widely used CNC machine tools. It is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer .

What Is CNC cutting? It is an exponentially controlled flame, plasma, laser and water jet cutting machine. It performs full-time, automatic, efficient, high-quality, and high-utilization CNC cutting according to the optimized nesting cutting program provided by the CNC cutting nesting software.Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting. This type of machining was originally performed mechanically on large complex machines.A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams.In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.

cnc machines offers up website

CNC cutting consists of two parts: the numerical control system and the mechanical structure. Compared with traditional manual and semi-automatic cutting, CNC cutting can effectively control and improve cutting quality and cutting efficiency through the cutting technology, cutting process and automatic control technology provided by the .The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .

These numerical control equipment includes machining centers, turning and milling centers, wire EDM equipment, thread cutting machines, etc. Cnc Machining processes workpieces in a continuous manner, which is suitable for large-volume, complex-shaped parts.CNC lathes are one of the most widely used CNC machine tools. It is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer .

What Is CNC cutting? It is an exponentially controlled flame, plasma, laser and water jet cutting machine. It performs full-time, automatic, efficient, high-quality, and high-utilization CNC cutting according to the optimized nesting cutting program provided by the CNC cutting nesting software.

cnc machine for steel cutting

cnc machine for plastic cutting

cnc machine for cutting metal

cnc cutting machine near me

To purchase a vintage Smokey Bear metal lunch box and thermos produced in 1972, you are looking at spending $795. Current Auction Value: Up to $800.00 USD

cnc cutting machine wiki|types of cnc machines and their applications