what does sheet metal gauge mean A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch. Gauge thickness applies differently depending on the . The new wheel is steel, vs the original brass, so that will be better compatible with an EP gear oil for lube - that's how I intend to go, moving forward. (EP gear oils can be corrosive to brass .

0 · steel sheet gauge size chart

1 · sheet metal sizing chart

2 · sheet metal gauge vs thickness

3 · sheet metal gauge sizes chart

4 · printable sheet metal gauge chart

5 · metal plate thickness chart

6 · metal plate gauge thickness chart

7 · metal gauge size chart

If you can't figure it out, the next time some of these balls appear, you should take clear photographs of the balls and the surrounding area and upload them to imgur so that others .

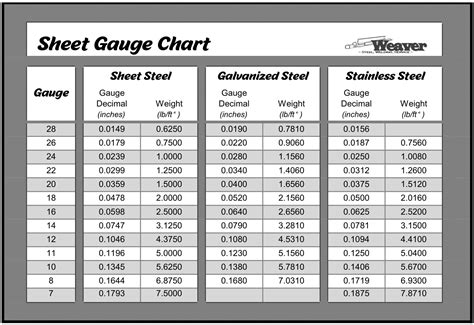

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material.

gkd metal fabrics kiwi

Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . A sheet metal gauge chart provides essential information that lets you choose accurate material measurements in construction, manufacturing, and engineering. Using these charts can help you enhance the quality of your . Sheet metal gauge refers to a standardized method used to measure and categorize the thickness of sheet metal. This system, which has its roots in the British iron wire .

A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch. Gauge thickness applies differently depending on the .What is a Sheet Metal Gauge Chart? A sheet metal gauge chart, also known as a sheet metal gauge table or sheet metal thickness chart, is a reference tool that provides a standardized measurement system for sheet metal thickness. Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the .

Gauges (sometimes spelled “gages” and abbreviated “GA”) are a standardized method of measuring and categorizing thin steel products such as sheets, coils, tubes, and wiring. As the gauge number increases, the material .

A sheet metal gauge is a standard unit of measure used to determine the thickness of a metal sheet. The gauge number and thickness have an inverse relationship – the higher .

In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the .

A sheet metal gauge chart, also known as a sheet metal gauge table or sheet metal thickness chart, is a reference tool that provides a standardized measurement system for sheet metal thickness. It offers a comparison . 10 gauge sheet metal is 3.42 mm thick for steel, 2.59 mm for aluminum, and 0.51 mm for zinc (from the OP’s wiki link). . "The use of gauge number is discouraged as being an archaic term of limited usefulness not having general agreement on meaning." Manufacturers' Standard Gauge for Sheet Steel is based on an average density of 41.82 lb per .What Does Gauge Mean in Sheet Metal? The actual thickness of the metal sheet is indicated as a unit of measurement referred to as “gauge.” Lower gauge numbers indicate a thicker metal sheet, and higher gauge numbers refer to a thinner metal sheet. The numbers have no relevance to common measurements, like inches or millimeters, as they are .

To learn about Sheet metal design in deep here is a course which can help : Basics of Sheet metal design for Mechanical design engineers. For more content on sheet metal design have a look at the list of articles here : Sheet metal bracket design. Sheet metal design guidelines. How to Stiffen Sheet metal design. Sheet metal Formability. Bend .From the cost perspective, as the gauge number of sheet metal goes down, indicating thicker steel, the cost of the safe or vault generally goes up. This is due to the increased material use and the enhanced protection that a lower sheet metal gauge chart a safe or vault provides. It's a balance of investment versus security.

Introduction to Sheet Metal Gauge. Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the thickness of metal sheets, plates, and wire. “Sheet metal gauges are the heart of sheet metal measurement in manufacturing. Since it is impossible to measure each sheet’s thickness with a conventional measurement tape, sheet metal gauges are used in this situation. In essence, a gauge represents the thickness of the sheet metal and can be expressed in millimeters or inches.Measuring sheet metal thickness using a gauge. The gauge number is the independent value that determines the thickness of sheet metal in terms of inches or millimetres. The higher the number, the thinner the sheet metal. Ferrous metal has a different gauge from nonferrous (such as copper) for which the unit of measurement is ounces per square foot.Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the number, the smaller the diameter, and now it is also used to indicate the .

Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch.

Sheet Metal Knowledge Menu . The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number increases, the material thickness decreases.

steel sheet gauge size chart

Ga. is the abbreviation of GAUGE, a length measurement unit of diameter originating in North America, belonging to the Brown & Sharpe measurement system.At the beginning of 1869, J.R. Brown and L. Sharp of the United States sold the outer micrometer developed for commercial sale, and initially established the measurement system.A sheet metal’s gauge can affect the methods used to cut, form and weld it. Gauges help engineers determine the most effective design and the path forward for manufacturing it. Fabricators, welders and machine operators also benefit from this knowledge since sheet metal gauges help determine the best methods to use. Aluminum Sheet Gauge: Understanding the Basics I. Introduction. Aluminum sheet gauge is a standardized measurement system used to indicate the thickness of an aluminum sheet metal.Understanding the gauge system is .

Generally pitch is along the member and gauge (or gage) is across, but no one remembers that and the two terms get used interchangeably in practice. If you need a mnemonic, the pitch of threads in a screw are along it’s length, and the .Discover the importance of steel gauge charts and how to use them effectively.A gauge chart denotes the thickness of sheet metal, with measurements provided in inches or millimeters. Interpreting the reading is straightforward: lower gauge values correspond to thicker sheet metal. Thickness and gauge values correlate directly. Meaning a thinner sheets will yield higher gauge readings. Most wire and sheet metal is sold only in even gauges. The majority of silversmithing work uses pieces of metal between 10 and 30 gauge, hence the gauge listing. The real question, then, is what we do with this information! Sheet Metal Gauges and Uses

Sheet Metal Gauge Thickness I have been trying to get this added in manually with the assistance of Graitec support and Autodesk support and it is overly complicated. Please add gauge thicknesses under the "Thickness" pulldown when creating plates.

A structural engineer will call for 20 gauge steel deck, for example, or a roof consultant will specify 24 gauge steel panels to be used in a standing seam metal roof. (Interestingly, aluminum roofing panels do not use gauge, and are described in inch decimals, 0.032″ being a common thickness.) Most other countries simply use millimeters. Sheet Metal Gauge Vs. Metal Gauge. At first glance, the terms "sheet metal gauge" and "metal gauge" might seem interchangeable. However, there's a subtle distinction. While the former specifically refers to flat pieces of metal, the latter encompasses various forms, including wires and rods. The term "gauge steel" is often used to refer to the .

The “Gage” or* “Gauge” of a piece of sheet metal is a number designation related to the thickness and weight per square foot of the metal. Gages for sheet metal range from 30 to 1, with a higher number indicating a thinner piece of material**. In typical architectural metal applications, even gages are used (i.e. [.] To provide clarity, this blog will explain the gauge system and include a helpful sheet metal gauge chart. The gauge system is a standardized method used to measure and categorize the thickness of sheet metal. It assigns a numerical value to different thicknesses, where a higher gauge number indicates a thinner sheet.

Gauges are used to specify the thickness of a sheet metal. Gauges are neither standard nor metric and the values are independent of those measurement systems. A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. For example, 18 gauge steel, according to a gauge conversion chart, is 0. . For instance, a purchaser may want a metal sheet that is 48 inches long by 96 inches wide. Without a specified tolerance, this could mean the purchaser wants a metal sheet that is 48.00000000 inches by 96.00000000 inches. This level of accuracy would generally be unachievable by the metal producer.

The "Cram into a circle" would mean that a wire of X gauge is half the diameter of a wire of 4X, and a quarter the diameter of a wire of 16X. . For instance sheet metal thickness, a gauge 1 could be .01 inch thich, gauge 2 could be 0.2 inch thich etc. In shotgun the measurement is different as it is the bore diameter, for instance a 12 gauge .

sheet metal sizing chart

(Jan 6, 2015) Jamie Steele said: Ok, i had a back up into my house. I had a company come out and pump the septic tank out (which was full of . See more

what does sheet metal gauge mean|metal gauge size chart