can vectric aspire run cnc machine View purchase and upgrade options and pricing for Aspire CNC software. . We’re an ISO 9001:2015-certified, large-capacity metal fabricator and weld shop serving diverse industries, from heavy manufacturing to technology to agriculture. Vance Metal recently .

0 · vcarve run cnc

1 · vcarve cnc not running

2 · does vcarve run cnc

3 · aspire rotary axis

4 · aspire cnc router software

5 · aspire 3d modeling tools

6 · aspire 3d machining software

7 · Vectric vcarve cnc

There is no box in the wall behind the existing light, just a hole in the sheetrock that they pulled the wires through and hooked up. There is a big support bracket that is screwed to the wall with drywall anchors.

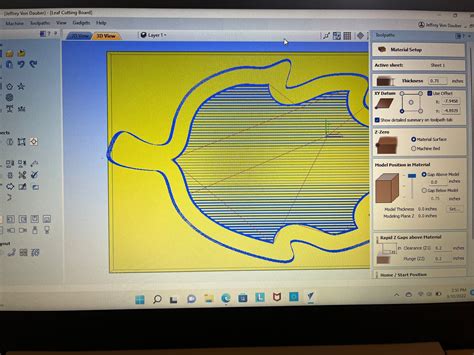

Aspire provides a powerful but intuitive software solution for creating and cutting parts on a CNC router. In addition to the 2D design and toolpath calculation tools Aspire adds 3D design tools which enable you to create your own 3D relief models and machine them with 3D machining .Trial Download - Aspire 〡VectricVCarve Pro - Aspire 〡VectricView purchase and upgrade options and pricing for Aspire CNC software. .

Using the built in clipart browser included in your Vectric software you can visually .The create set-up job sheet command allows you to create a summary sheet .Our online training video's guide you through the process of getting started ."VCarve Pro has enabled me to create anything I can dream up. It is by far the .

Cut3D is a dedicated toolpath engine for CNC machining 3D models. Cut3D's .Here you will be able to access our library of gadgets for VCarve Pro and Aspire, .

vcarve run cnc

Aspire Upgrade Page - Aspire 〡Vectric I am contemplating the purchase of a CNC mill with a 4th axis (a rotary indexer) connected to its own port but I am not sure that Aspire can really generate toolpaths for . Post processors do not run machines, they create code that is then sent to a machine controller which runs the machine. VCarve produces the code to run the machine by .Much of the functionality of Cut3D have been adopted by VCarve and Aspire. Vectric software can be run with CPU rendering as fallback. If you are unsure .

Think I'll take the suggestion to upgrade to a refurbished computer to run the Aspire. Use my CNC computer then for running the Mach3 machining program. Which works . Vectric's "Output direct to machine" only works with a very limited number of controller types Mach3 and GRBL controllers are the most frequently used . The centroid .

This is the file that you can come back to any time at a later date to continue your work or to duplicate as the basis of a new project. Note that this is *not* the file that your CNC . As we've discussed, the actual motion of your CNC machine (the toolpath) required to cut al shape can be complex and difficult to interpret. Luckily your software provides an . Probably the biggest issue with trying to use Aspire to program a CNC lathe is the roughing routines. I have not seen anything in Aspire that would work. And yup, I can do it by .

You should run VTransfer on the PC to which your CNC machine is connected via a USB serial connection. If your Vectric CADCAM software is also running on the same PC, you can use .Aspire provides a powerful but intuitive software solution for creating and cutting parts on a CNC router. In addition to the 2D design and toolpath calculation tools Aspire adds 3D design tools which enable you to create your own 3D relief models and machine them with 3D . I am contemplating the purchase of a CNC mill with a 4th axis (a rotary indexer) connected to its own port but I am not sure that Aspire can really generate toolpaths for simultaneous use of all 4 axes machines.

Post processors do not run machines, they create code that is then sent to a machine controller which runs the machine. VCarve produces the code to run the machine by using a post processor. Hope that helps.Much of the functionality of Cut3D have been adopted by VCarve and Aspire. Vectric software can be run with CPU rendering as fallback. If you are unsure your computer meets minimum requirements, download a free trial

vcarve cnc not running

Think I'll take the suggestion to upgrade to a refurbished computer to run the Aspire. Use my CNC computer then for running the Mach3 machining program. Which works great, other than the first program I tried, and the Mach3 program had a bug in it and failed to change the millimeters into inches.

Vectric's "Output direct to machine" only works with a very limited number of controller types Mach3 and GRBL controllers are the most frequently used . The centroid machine is not supported for this functionality. I recently installed a Centroid Acorn board on .

This is the file that you can come back to any time at a later date to continue your work or to duplicate as the basis of a new project. Note that this is *not* the file that your CNC machine will read. Saving Toolpaths (see below) is the indepenendent process by which you specifically save the file from this project that your CNC machine needs. As we've discussed, the actual motion of your CNC machine (the toolpath) required to cut al shape can be complex and difficult to interpret. Luckily your software provides an extremely accurate preview of any toolpaths that you create by . Probably the biggest issue with trying to use Aspire to program a CNC lathe is the roughing routines. I have not seen anything in Aspire that would work. And yup, I can do it by drawing the paths, but that is not exactly very user friendly.You should run VTransfer on the PC to which your CNC machine is connected via a USB serial connection. If your Vectric CADCAM software is also running on the same PC, you can use Direct Output mode to send toolpaths to VTransfer directly, without the need for file saving or loading.

Aspire provides a powerful but intuitive software solution for creating and cutting parts on a CNC router. In addition to the 2D design and toolpath calculation tools Aspire adds 3D design tools which enable you to create your own 3D relief models and machine them with 3D .

I am contemplating the purchase of a CNC mill with a 4th axis (a rotary indexer) connected to its own port but I am not sure that Aspire can really generate toolpaths for simultaneous use of all 4 axes machines. Post processors do not run machines, they create code that is then sent to a machine controller which runs the machine. VCarve produces the code to run the machine by using a post processor. Hope that helps.Much of the functionality of Cut3D have been adopted by VCarve and Aspire. Vectric software can be run with CPU rendering as fallback. If you are unsure your computer meets minimum requirements, download a free trial

Think I'll take the suggestion to upgrade to a refurbished computer to run the Aspire. Use my CNC computer then for running the Mach3 machining program. Which works great, other than the first program I tried, and the Mach3 program had a bug in it and failed to change the millimeters into inches. Vectric's "Output direct to machine" only works with a very limited number of controller types Mach3 and GRBL controllers are the most frequently used . The centroid machine is not supported for this functionality. I recently installed a Centroid Acorn board on .

This is the file that you can come back to any time at a later date to continue your work or to duplicate as the basis of a new project. Note that this is *not* the file that your CNC machine will read. Saving Toolpaths (see below) is the indepenendent process by which you specifically save the file from this project that your CNC machine needs. As we've discussed, the actual motion of your CNC machine (the toolpath) required to cut al shape can be complex and difficult to interpret. Luckily your software provides an extremely accurate preview of any toolpaths that you create by . Probably the biggest issue with trying to use Aspire to program a CNC lathe is the roughing routines. I have not seen anything in Aspire that would work. And yup, I can do it by drawing the paths, but that is not exactly very user friendly.

does vcarve run cnc

aspire rotary axis

Metalcort ha diseñado y probado un exitosa técnica de inyección de guías para bombeo de cavidades progresivas y bombeo mecánico, con las 50000 guías inyectadas. Tenemos materiales para cada aplicación, contáctanos para ayudarlos en el diseño del pozo.

can vectric aspire run cnc machine|aspire 3d machining software