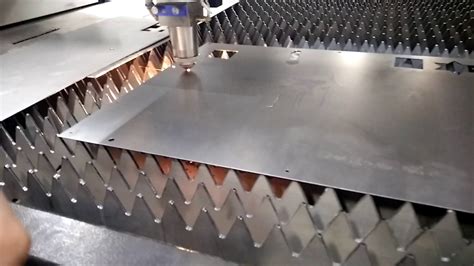

can you laser cut sheet metal Laser cutting fabrication uses a high-power beam of light (laser) to cut out flat and thin sheets of metals. The process is directed by optics and computer numerical control (CNC) technology, which accounts for the high precision of laser cut parts.

The most extensive variety of tabs and brackets in one location on the web, over 500 different tabs, stamped or cut from high-quality steel, for a variety of uses.

0 · wholesale sheet metal laser cutting

1 · sheet metal cutting near me

2 · laser metal cutting near me

3 · laser cut website

4 · hobby laser cutter for metal

5 · desktop laser cutter for metal

6 · best sheet metal laser cutter

7 · 24x24 sheet metal laser cutter

In the back of a metal junction box will be a "nub" which is threaded for a 10-32 screw. This is for a ground wire. I suppose that what you have found by the two really good answers is that the term "sockets" and "outlets" are not very definitive.

This article highlights the important aspects of Laser Cutting Sheet Metal, Laser types suitable for cutting sheet metals, and optimal machining processes. Besides this, we’ll examine merits, and demerits, and discuss .

When it comes to cutting sheet metal, multiple laser cutting machines and equipment can tackle distinctive jobs. For example, plasma cutting is a popular process for a wide array of metal sheets, like stainless steel, mild .Sheet metal laser cutting is a process where a high-powered laser beam is cut through various types of sheet metal. The laser melts, burns, or vaporizes the material, creating precise and . Laser cutting is a CNC (computer numerical control) technique in precision sheet metal fabrication. It uses high-power laser beams to cut sheet metal into exact specifications. . Diving into the world of laser cutting sheet metal can seem daunting, but not anymore. In this comprehensive guide, we’ll walk you through all the key aspects of the process. From understanding the basics, choosing the .

Laser cutting fabrication uses a high-power beam of light (laser) to cut out flat and thin sheets of metals. The process is directed by optics and computer numerical control (CNC) technology, which accounts for the high precision of laser cut parts.

wholesale sheet metal laser cutting

sheet metal cutting near me

This article highlights the important aspects of Laser Cutting Sheet Metal, Laser types suitable for cutting sheet metals, and optimal machining processes. Besides this, we’ll examine merits, and demerits, and discuss essential considerations for this technology. When it comes to cutting sheet metal, multiple laser cutting machines and equipment can tackle distinctive jobs. For example, plasma cutting is a popular process for a wide array of metal sheets, like stainless steel, mild steel, or aluminum.Sheet metal laser cutting is a process where a high-powered laser beam is cut through various types of sheet metal. The laser melts, burns, or vaporizes the material, creating precise and intricate cuts. Controlled by a computer, the laser follows a pre-determined path, ensuring accuracy and efficiency in producing prototypes and mass . Laser cutting is a CNC (computer numerical control) technique in precision sheet metal fabrication. It uses high-power laser beams to cut sheet metal into exact specifications. The cutting technique uses an adjusted focus light and an assist gas. The light and gas typically burn any metal into the desired shape or size.

Diving into the world of laser cutting sheet metal can seem daunting, but not anymore. In this comprehensive guide, we’ll walk you through all the key aspects of the process. From understanding the basics, choosing the right laser, and achieving perfect cuts, we've covered everything. Laser cutting, a revolutionary technology in precision sheet metal fabrication, has transformed modern manufacturing processes, offering unparalleled accuracy and efficiency. This comprehensive guide explores the intricacies of laser cutting, its advantages, types of lasers used, suitable materials, machine configurations, and much more.Sheet metal laser cutting harnesses the power of concentrated light to cut through metal precisely and efficiently. Read on to discover how sheet metal laser cutting is indispensable to the automotive, aerospace, and electronic industries.

In layman's terms, sheet metal laser cutting is a process where a high-powered laser beam is used to cut, engrave, or shape metal sheets. This method stands out for its precision, speed, and flexibility, making it a go-to choice for various industries, including automotive, aerospace, and electronics. But it's not just about cutting metal. In sheet metal laser cutting, a Computer Numerical Control (CNC) system directs a concentrated laser beam across the metal. This beam “subtracts” material by melting, burning, or vaporizing along the programmed path.

laser metal cutting near me

Laser cutting fabrication uses a high-power beam of light (laser) to cut out flat and thin sheets of metals. The process is directed by optics and computer numerical control (CNC) technology, which accounts for the high precision of laser cut parts. This article highlights the important aspects of Laser Cutting Sheet Metal, Laser types suitable for cutting sheet metals, and optimal machining processes. Besides this, we’ll examine merits, and demerits, and discuss essential considerations for this technology.

When it comes to cutting sheet metal, multiple laser cutting machines and equipment can tackle distinctive jobs. For example, plasma cutting is a popular process for a wide array of metal sheets, like stainless steel, mild steel, or aluminum.Sheet metal laser cutting is a process where a high-powered laser beam is cut through various types of sheet metal. The laser melts, burns, or vaporizes the material, creating precise and intricate cuts. Controlled by a computer, the laser follows a pre-determined path, ensuring accuracy and efficiency in producing prototypes and mass . Laser cutting is a CNC (computer numerical control) technique in precision sheet metal fabrication. It uses high-power laser beams to cut sheet metal into exact specifications. The cutting technique uses an adjusted focus light and an assist gas. The light and gas typically burn any metal into the desired shape or size. Diving into the world of laser cutting sheet metal can seem daunting, but not anymore. In this comprehensive guide, we’ll walk you through all the key aspects of the process. From understanding the basics, choosing the right laser, and achieving perfect cuts, we've covered everything.

cnc turning parts processing

Laser cutting, a revolutionary technology in precision sheet metal fabrication, has transformed modern manufacturing processes, offering unparalleled accuracy and efficiency. This comprehensive guide explores the intricacies of laser cutting, its advantages, types of lasers used, suitable materials, machine configurations, and much more.Sheet metal laser cutting harnesses the power of concentrated light to cut through metal precisely and efficiently. Read on to discover how sheet metal laser cutting is indispensable to the automotive, aerospace, and electronic industries.In layman's terms, sheet metal laser cutting is a process where a high-powered laser beam is used to cut, engrave, or shape metal sheets. This method stands out for its precision, speed, and flexibility, making it a go-to choice for various industries, including automotive, aerospace, and electronics. But it's not just about cutting metal.

laser cut website

The chassis is the outer structural framework of a laptop that encloses and protects all the internal components. It is typically made of plastic or metal and plays a key role in determining the laptop’s overall design and durability.

can you laser cut sheet metal|best sheet metal laser cutter