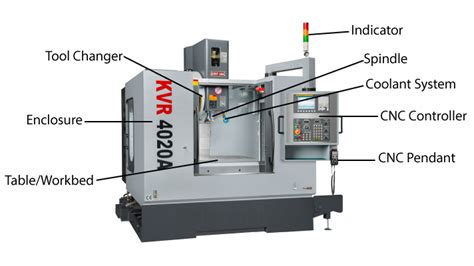

cnc machine and vmc machine A VMC machine, also known as a vertical machining center, is a type of CNC (Computer Numerical Control) milling machine that utilizes a vertically oriented spindle to remove material from a workpiece. It is widely used in various . Injection Molding for a custom manufacturing project is an intricate and .

0 · vmc machine shop

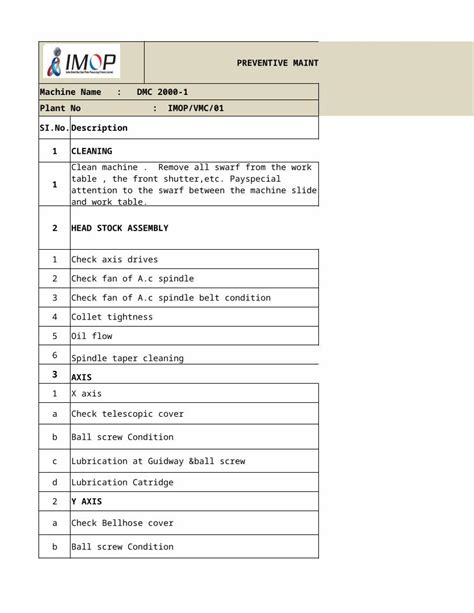

1 · vmc machine check list

2 · vmc machine basic knowledge

3 · vmc full form machine

4 · types of vmc machine

5 · haas vmc machine price

6 · difference between vmc and hmc

7 · cnc and vmc full form

Aluminum CNC Machining. Receive assembly-ready parts on time. Moseys is a trusted provider of high-quality machining for aluminum parts. Leverage decades of experience serving some of America’s largest manufacturers with precision .

Each type of CNC machine is designed to perform a particular set of operations, with structures optimized for those tasks. The diversity in design allows CNC machines to be tailored to .A VMC machine, also known as a vertical machining center, is a type of CNC (Computer Numerical Control) milling machine that utilizes a vertically oriented spindle to remove material from a workpiece. It is widely used in various .

A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to .

A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in .2. Machine Structure: VMC machines typically have a fixed table and a moving column, allowing for easy access to the workpiece from various angles. On the other hand, CNC machines can .

VMC machines are typically equipped with a computer numerical control (CNC) system, which governs the machine’s movements and machining operations. The CNC system interprets machining instructions from a program, translates them .Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting .

vmc machine shop

Each type of CNC machine is designed to perform a particular set of operations, with structures optimized for those tasks. The diversity in design allows CNC machines to be tailored to specific manufacturing needs. VMC: Typically features a fixed table and a vertical spindle. The spindle moves in the X, Y, and Z axes to perform machining .

A VMC machine, also known as a vertical machining center, is a type of CNC (Computer Numerical Control) milling machine that utilizes a vertically oriented spindle to remove material from a workpiece. It is widely used in various industries for .A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work. . Gantry-Style CNC Machines for Large Workpieces CNY ONLY. Gantry Series details > CNY ONLY. SR Sheet Routers. ER32 / ISO30 Taper; 3 .

A VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other types of milling machines is that the spindle axis of a VMC is oriented vertically, rather than horizontally.

A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in contemporary manufacturing for producing complex and intricate parts with .

vmc machine check list

2. Machine Structure: VMC machines typically have a fixed table and a moving column, allowing for easy access to the workpiece from various angles. On the other hand, CNC machines can have different configurations, including horizontal, vertical, or multi-axis setups. 3. Machining Operations: While both CNC and VMC machines can perform a wide .

VMC machines are typically equipped with a computer numerical control (CNC) system, which governs the machine’s movements and machining operations. The CNC system interprets machining instructions from a program, translates them into precise movements of the machine axes, and executes the desired machining tasks with accuracy and repeatability.Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting applications, CNC finds a special place. 3. In CNC, a manual intervention is required for changing the tool.

A Vertical Machining Center (VMC) is a type of CNC machine where the spindle axis is vertically oriented. VMCs are widely used for milling, drilling, tapping, and other machining operations. Features of VMC. Vertical Spindle Orientation: The spindle is vertical, making it suitable for operations requiring downward cutting forces.What is Vertical Machining Center – How to Define CNC Vertical Machining Center. Vertical machining center (VMC) refers to the machining center of which the spindle axis and the worktable set vertically, it can perform milling, boring, .

Each type of CNC machine is designed to perform a particular set of operations, with structures optimized for those tasks. The diversity in design allows CNC machines to be tailored to specific manufacturing needs. VMC: Typically features a fixed table and a vertical spindle. The spindle moves in the X, Y, and Z axes to perform machining .A VMC machine, also known as a vertical machining center, is a type of CNC (Computer Numerical Control) milling machine that utilizes a vertically oriented spindle to remove material from a workpiece. It is widely used in various industries for .

A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work. . Gantry-Style CNC Machines for Large Workpieces CNY ONLY. Gantry Series details > CNY ONLY. SR Sheet Routers. ER32 / ISO30 Taper; 3 .A VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other types of milling machines is that the spindle axis of a VMC is oriented vertically, rather than horizontally. A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in contemporary manufacturing for producing complex and intricate parts with .2. Machine Structure: VMC machines typically have a fixed table and a moving column, allowing for easy access to the workpiece from various angles. On the other hand, CNC machines can have different configurations, including horizontal, vertical, or multi-axis setups. 3. Machining Operations: While both CNC and VMC machines can perform a wide .

vmc machine basic knowledge

VMC machines are typically equipped with a computer numerical control (CNC) system, which governs the machine’s movements and machining operations. The CNC system interprets machining instructions from a program, translates them into precise movements of the machine axes, and executes the desired machining tasks with accuracy and repeatability.Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting applications, CNC finds a special place. 3. In CNC, a manual intervention is required for changing the tool.

A Vertical Machining Center (VMC) is a type of CNC machine where the spindle axis is vertically oriented. VMCs are widely used for milling, drilling, tapping, and other machining operations. Features of VMC. Vertical Spindle Orientation: The spindle is vertical, making it suitable for operations requiring downward cutting forces.

ornamental metal box

ospard stainless steel insulated lunch box

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

cnc machine and vmc machine|vmc machine shop