cnc lathe machine g codes and m codes Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

Vendo torno pinacho cnc mod rayo 180 con portapinzas hidráulico, contrapunto hidráulico, torreta de 8 herramientas, control fagor 8055, 360 mm sobre bancada, 750 entre puntos, 4000 rpm, motor 5 5kw, diametro del usillo 42 mm, cargador de barras neumático de 120 cm, recoge piezas neumático, año 2004, en muy buenas condiciones y trabajando.

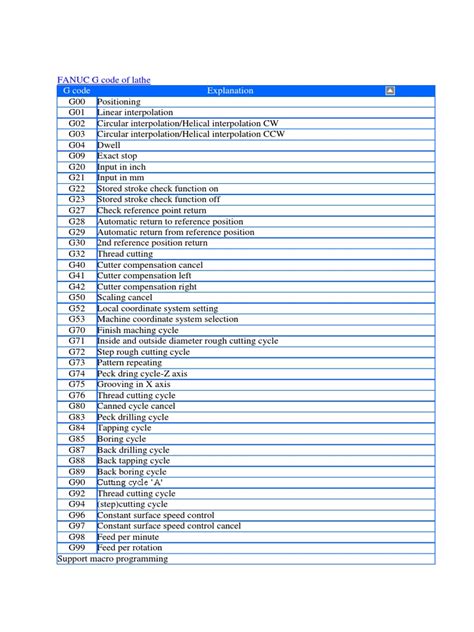

0 · list of g codes cnc

1 · list of fanuc g codes

2 · cnc turning g code list

3 · cnc mill g code list

4 · cnc lathe g codes list

5 · cnc lathe g code examples

6 · cnc g code list download

7 · cnc g code chart

$55.99

Jun 26, 2024

An alarm code may indicate a problem with the CNC machine (mechanical or .G-Wizard G-Code Editor. The market leader used by 100,000+ CNC'ers at thousands . CNC G-codes & M Codes for milling and turning with explanations, .4 | P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. .

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin.

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing.

In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” .

G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non .Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming. Click here for a Handy g-code and m-code programming reference list for CNC Lathes and Turning Centers with examples

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)4 | P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin.

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool. G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non-movement operations of the programming.

Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming. Click here for a Handy g-code and m-code programming reference list for CNC Lathes and Turning Centers with examples

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)4 | P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin.

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system .

list of g codes cnc

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool.

G-codes differ in different CNC machines, while M-codes are the same in most CNC machines. G-codes command the machine’s motion and function for the product’s design, while M-codes are used to conduct the non-movement operations of the programming.

arlington electrical box for siding

Nop’s Metalworks is a professional services company specializing in metal smithing, fabrication, and implementation of large-scale custom engineering projects.

cnc lathe machine g codes and m codes|cnc g code list download