cnc lathe machine g code m code list 1. What are the purposes of G-codes and M-codes in CNC machining? G-codes and M-codes are essential for CNC machining operations. G-codes (Geometric Codes) direct the machine on movements and paths, .

$38.99

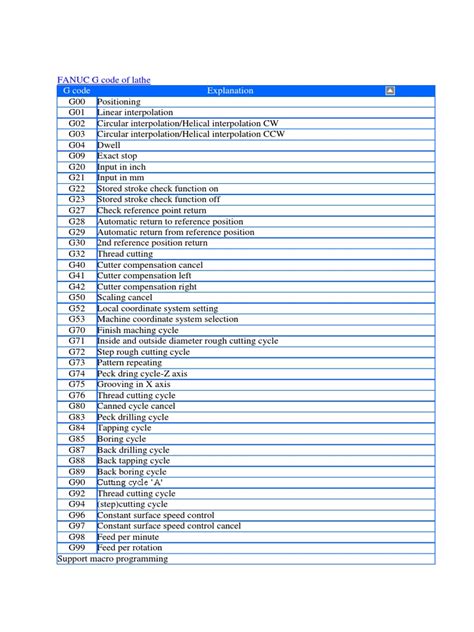

0 · list of fanuc g codes

1 · g m code cheat sheet

2 · g code table listing

3 · complete g code list

4 · cnc turning g code list

5 · cnc lathe g code examples

6 · cnc g code list download

7 · cnc g code cheat sheet

Aluminum isn’t magnetic under normal circumstances, but it does interact with magnets – we call this paramagnetism. This metal isn’t attracted to magnets, so a magnet won’t stick to aluminum. However, when a magnet moves close to aluminum, it causes an electrical field, which interacts with the aluminum.

Jun 26, 2024 An alarm code may indicate a problem with the CNC machine (mechanical or .

A G-Code Editor and Simulator with Everything You Need. Get started in . CNC G-codes & M Codes for milling and turning with explanations, .

Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin. 1. What are the purposes of G-codes and M-codes in CNC machining? G-codes and M-codes are essential for CNC machining operations. G-codes (Geometric Codes) direct the machine on movements and paths, . Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.

To select the appropriate G-codes and M-codes for programming based on different CNC systems, a comprehensive approach considering system specifics, processing requirements, and industry best practices is essential.

Click here for a Handy g-code and m-code programming reference list for CNC Lathes and Turning Centers with examples

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin. 1. What are the purposes of G-codes and M-codes in CNC machining? G-codes and M-codes are essential for CNC machining operations. G-codes (Geometric Codes) direct the machine on movements and paths, such as: G00: Rapid Positioning; G01: Linear Interpolation; G02: Circular Interpolation Clockwise; G03: Circular Interpolation Counterclockwise Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download. To select the appropriate G-codes and M-codes for programming based on different CNC systems, a comprehensive approach considering system specifics, processing requirements, and industry best practices is essential.G1 are the same. The same holds true for M codes, position commands, feed rates, etc. When specifying values for position, feed rate, variables, etc., it is good practice to always use a decimal point and trailing zero, instea. of X1 use X1.0. Although the decimal point is not required (in Mach X1 = X1.0) it is HI. G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end CNC machined product. M-Code is used for specific applications.

list of fanuc g codes

g m code cheat sheet

g code table listing

complete g code list

cnc turning g code list

Safeguard outdoor electric wires and cable terminals from dust and low-pressure water jets with an IP55 junction box. IP55 junction boxes are ideal for low-level weather damage protection. Find waterproof socket covers to keep electricals safe from dust and water jets.

cnc lathe machine g code m code list|g m code cheat sheet