cnc lathe machine components Here, we will explore the main components that make up a CNC lathe machine. We will take a closer look at the bed and headstock, tailstock and carriage, chuck and spindle, tool turret and . As CNC machines have grown in capability and popularity, they're finding their way into more and more home shops. With small footprints and relatively low price tags, benchtop CNCs—essentially robotic routers—provide a good way to .

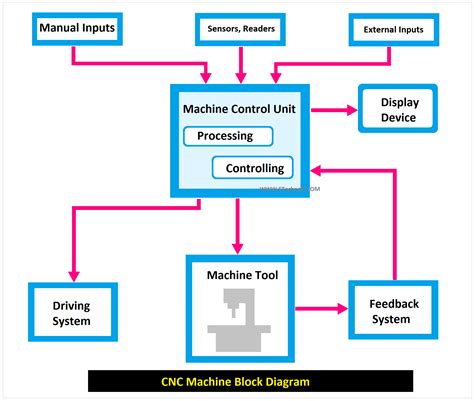

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · cnc machine parts list pdf

3 · cnc machine parts diagram

4 · cnc machine components list

5 · cnc lathe machine diagram

6 · cnc lathe headstock

7 · block diagram of cnc machine

FBS Floor Box Systems supplies floor boxes and covers for concrete, raised and wood floors that provide convenient access to power outlets, AV and data jacks. FBS products are Made in USA and second to none.

An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.

Understanding the key components of a CNC lathe machine is crucial for grasping how these machines achieve such high levels of precision. Let’s break down each part and its role in the .Here, we will explore the main components that make up a CNC lathe machine. We will take a closer look at the bed and headstock, tailstock and carriage, chuck and spindle, tool turret and .

The vertical turning centers are used for heavy components, horizontal types are used widely for the general applications, so let’s explain 8 parts of a CNC lathe! 1. Headstock. The first part of CNC lathe is headstock .When it comes to modern manufacturing, nothing beats the precision and efficiency of CNC lathe machines. If you’re in need of a quick rundown, here are the main parts of a CNC lathe: CNC .

Learn about the main components of CNC lathe machine, from the spindle assembly to the control panel. See how each part affects the CNC machining process. A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the . Our exploration will cover the essential elements that comprise a CNC lathe machine, starting with the headstock, an integral part that houses the machine’s spindle. We will also examine the lathe bed, the foundation upon . CNC lathes have a series of distinct elements that identify them for what they are. This article will focus on defining CNC lathes, identifying the lathe machine’s parts, examining how each element works, and advising about optimal use. Here is an image of how a CNC lathe looks with major parts labeled: 1. Headstock.

An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.

Understanding the key components of a CNC lathe machine is crucial for grasping how these machines achieve such high levels of precision. Let’s break down each part and its role in the process.Here, we will explore the main components that make up a CNC lathe machine. We will take a closer look at the bed and headstock, tailstock and carriage, chuck and spindle, tool turret and tooling, control panel and software, as well as the coolant system. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts.

The vertical turning centers are used for heavy components, horizontal types are used widely for the general applications, so let’s explain 8 parts of a CNC lathe! 1. Headstock. The first part of CNC lathe is headstock which is located in the left side of the machine.

When it comes to modern manufacturing, nothing beats the precision and efficiency of CNC lathe machines. If you’re in need of a quick rundown, here are the main parts of a CNC lathe: CNC lathes have come a long way since their origins, which trace back to primitive woodworking lathes and potters’ wheels. Learn about the main components of CNC lathe machine, from the spindle assembly to the control panel. See how each part affects the CNC machining process. A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer. Our exploration will cover the essential elements that comprise a CNC lathe machine, starting with the headstock, an integral part that houses the machine’s spindle. We will also examine the lathe bed, the foundation upon which all other parts are mounted, and the chuck, which holds the workpiece in place.

CNC lathes have a series of distinct elements that identify them for what they are. This article will focus on defining CNC lathes, identifying the lathe machine’s parts, examining how each element works, and advising about optimal use. Here is an image of how a CNC lathe looks with major parts labeled: 1. Headstock. An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.Understanding the key components of a CNC lathe machine is crucial for grasping how these machines achieve such high levels of precision. Let’s break down each part and its role in the process.

ikea fabric chair metal frame 2015

Here, we will explore the main components that make up a CNC lathe machine. We will take a closer look at the bed and headstock, tailstock and carriage, chuck and spindle, tool turret and tooling, control panel and software, as well as the coolant system. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. The vertical turning centers are used for heavy components, horizontal types are used widely for the general applications, so let’s explain 8 parts of a CNC lathe! 1. Headstock. The first part of CNC lathe is headstock which is located in the left side of the machine.When it comes to modern manufacturing, nothing beats the precision and efficiency of CNC lathe machines. If you’re in need of a quick rundown, here are the main parts of a CNC lathe: CNC lathes have come a long way since their origins, which trace back to primitive woodworking lathes and potters’ wheels.

Learn about the main components of CNC lathe machine, from the spindle assembly to the control panel. See how each part affects the CNC machining process. A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer.

schematic diagram of cnc machine

Industrial 5x10 CNC woodworking machine comes with dual rotary ATC kits with 2 drum tool changers, including 24 router bits, which is an automatic CNC wood router table for cabinets and furniture making.

cnc lathe machine components|block diagram of cnc machine