cnc machining tolerances CNC turning and millingare known for the high quality and precision they can provide. At the same time, engineers need to be wary of a few important aspects when choosing the . See more A metal fabricator is a skilled craftsperson who cuts, bends and joins metal pieces to construct various structures and products. From intricate engine parts to sturdy steel bridges, metal fabricators contribute to various industries and projects important to societal development.

0 · typical tolerances of manufacturing processes

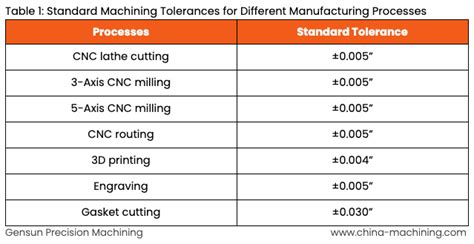

1 · typical cnc machine tolerance

2 · standard tolerance chart for machining

3 · machining tolerances chart

4 · how accurate are cnc machines

5 · cnc tolerance chart

6 · cnc machining tolerance chart

7 · cnc machine tolerance standards

An elegant custom address plaque provides that extra detail to boost your home's appearance, curb appeal and value. Each plaque is custom .

Learn what CNC machining tolerances are, why they are important, and how to choose the right ones for your parts. Find out about general, limit, unilateral, bilateral, and GD&T tolerances, and their effects on cost and quality. See moreWhile CNC machining servicesare highly accurate when it comes to product dimensions, they are not perfect. The final measurements between any two parts made using the . See more

Engineering tolerancesare a necessary requirement when defining product measurements. Unless the customer specifies any certain tolerances, the parts will usually be made . See moreCNC turning and millingare known for the high quality and precision they can provide. At the same time, engineers need to be wary of a few important aspects when choosing the . See moreNow that we understand why we need tolerance limits and its various types, let’s look at why selecting the right limit is important. The appropriate tolerance limit ensures flawless part . See moreStandardized Tolerances for CNC Machining. The standard prototype and production machining tolerance at Protolabs is +/- 0.005 in. (0.13mm). This means any part feature’s location, width, length, thickness, or diameter will not .

typical tolerances of manufacturing processes

CNC Machining is Essential for Tight Tolerances Tight tolerance machining benefits industries that require high levels of accuracy and consistency. Although it presents challenges such as higher costs, longer .Fine-tuning tolerances in CNC machining is a critical aspect of producing high-quality, reliable parts. By understanding the importance of tolerances, evaluating design requirements, and collaborating with manufacturers, you can achieve . Read on to learn more about the concept of machining tolerances, how they are measured and calculated, and the different types of CNC machining tolerances. What is Machining Tolerance? Machining tolerance, also known .

Engineering Tolerances. The most commonly used tolerancing system for shafts and holes is detailed in ISO 286-1 & 286-2. The first provides the charts for the fundamental deviations (G, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (H7, g6, etc.) can be calculated. 5. Limit Tolerances. A limit tolerance is expressed as a range of values, where the part is fine as long as the measurement falls between that range. 13 – 13.5mm for example is a limit tolerance for CNC machining indicating that the part must have a measurement that falls between the upper and the lower limit (13mm is the upper limit and 13.5mm is the lower limit).Learn how ISO 2768 standardizes general tolerances for machined parts, improving precision and reducing errors in manufacturing. This guide covers Part 1 (linear and angular dimensions) and Part 2 (geometrical tolerances), commonly used in CNC machining and tooling industries. Discover how ISO 2768 helps streamline technical drawings, ensuring global consistency and . CNC machining tolerances are important parameters when manufacturing products, no matter their intended applications. Nowadays, most industrial and consumer products require consistency to meet manufacturing standards. Hence, product manufacturers rely on types of CNC machines for high accuracy in their manufacturing projects. However, it is .

CNC machining tolerances are the allowable deviations from the specified dimensions of a part. They define the range within which the actual measurements of a part can vary while still being acceptable. Tolerances ensure that parts fit together correctly and function as intended, maintaining the quality and reliability of the final product. . Common CNC machining tolerances vary based on the machine’s capabilities and the material being machined. The tolerance CNC range can go from ±0.001 inches (±0.025 mm) for high-precision machines to ±0.010 inches (±0.25 mm) . There are various types of tolerances in CNC machining. Here are the most common tolerances used in CNC machine shops: Standard Tolerances. Most product designers and engineers utilize standard machining tolerances for most commonly machined parts. Machined parts, such as pins, threads, pipes, etc., often use standard machining tolerances.

Machine tolerances: Depending on the type of CNC machine, they also have their own restriction and range of achievable accuracy while machining. Generally, CNC machines are capable of maintaining a tolerance of ± 0.0025mm (Fan J, 2021) Learn about standard and typical tolerances in machining with our CNC machining tolerance chart. Ever wondered what CNC machining tolerances are? Click here to learn all about machining tolerances, standard machining t. Skip to content. Next Start Date. Next Start. November 18th, 2024. 1-800-834-7308; Enroll Now; Request Info;

Tolerances in CNC machining are defined as the acceptable range a parameter can deviate from its intended value. A parameter may be a measurable physical property such as temperature, humidity, noise levels, stress, solar irradiance and speed, or a physical dimension, for example, the definition of space.

Learn about tolerances for CNC machining, including how designing tighter tolerances can affect costs, the choice of the manufacturing process, inspection options, and materials. Tolerance is the acceptable range for a dimension which is determined by the designer based on the form, fit and function of a part. Unless specifically called out by .CNC Machining Tolerances. We offer varying levels of precision depending on your design requirements. We can manufacture and validate both coordinate tolerances and geometric tolerances (GD&T). Our standard precision, . Standards for CNC Machining Tolerances. Tolerances, like other machining aspects, are governed by some standards. International standards that define machining tolerances are: ISO 2768. This standard defines general tolerances for linear and angular dimensions, chamfers, and radii. It helps simplify the process by providing default tolerances .

In your case however, your tolerance in case of TPdiameter is .028/2+bonus tol, so the true position is +/- .014 + hole dia tolerance. To translate that, if your hole is .500 +/-.005, TP.028 MMC, and you want to make a receiving gage to check true position, you'd make the gage hole to be .481 with the sliding pin.Definition and Concept of CNC Machining Tolerances. CNC machining tolerances define the allowable variation in a part's dimensions, ensuring the necessary precision in manufacturing. These tolerances are vital because they set the acceptable range within which a part's actual dimensions can differ from its nominal or intended dimensions. For . The CNC Turning Center is one of the critical devices in today’s machining environment, as it allows the manufacture of complex parts with high levels of accuracy and productivity. This document addresses the parameters for mastering the CNC Turning Center, providing a consistent framework for machinists and engineers to develop their skills using .What are CNC Machining Tolerances? The tolerance of a cnc machined part is simply the amount of variation allowed in the dimension of the final manufactured part. This indicates the level of precision required for the part. Engineers specify tolerance by setting two values known as the upper and lower limits of the part’s dimension.

These tolerances are crucial in CNC machining, as they ensure that parts fit together correctly and operate as intended, while also accounting for the inherent limitations of the machining process. Tolerances are typically specified as a plus/minus value, ±0.01 mm, indicating the acceptable variation in the final dimensions. Tolerances in Different Manufacturing Processes. Tolerances vary across different manufacturing processes, each of which has its strengths and limitations: CNC Machining: CNC machining offers highly controlled tolerances, often as tight as +/- 0.002 in. for production parts. This process is ideal for precision parts, especially in industries . CNC machining tolerances refer to the allowable variations within a specific range for a parameter during the CNC machining process. This parameter can be any measurable physical attribute, such as temperature, humidity, or a physical dimension like a spatial measurement. Tolerances define the acceptable range of actual parameter values . This article explains what CNC machining tolerances are, how they’re determined, the different types of CNC tolerances, and our best tips for CNC machining tolerances. Pro-Tip: For more check out our GD&T Visual Guide to see how tolerances are applied. What is a CNC Machining Tolerance?

I think the tolerance block is kind of sitting there like a watermark on the page, the designer doesn't even regard it. For example, I see drawings for mill and for lathe turned parts with the exact same tolerance block (like x.xxx=+/-.005") and anyone with a lick of sense knows that if you crank out lathe turned parts at +/-.005, nobody is going to be happy with what you're . Precision is the cornerstone of CNC machining, and within this realm, CNC machining tolerance takes center stage. Tolerance dictates the allowable variations in dimensions, ensuring that manufactured components meet exact specifications. In this article, we will discuss the role of tolerance in CNC machining, and different types of CNC tolerances.

typical cnc machine tolerance

standard tolerance chart for machining

machining tolerances chart

sheet metal central florida

Our selection of Roper Whitney replacement parts includes genuine components designed to seamlessly integrate with your equipment, ensuring optimal performance and longevity. From .

cnc machining tolerances|how accurate are cnc machines