welding sheet metal between tubes space frame increase strength CORNERS AND WELDING. Proper technique on corners that need to be welded is necessary to reduce cost and increase the overall strength of the corners. Approved Sheet . Custom Metal Creations from Wailuku, HI. Company specialized in: Metal Fabricators. Please call us for more information - (808) 244-1468

0 · welding hollow structural sections

1 · welding a steel tube

2 · welded tube to tube sheet strength

3 · welded tube to tube sheet joint

4 · weld for tube to tube sheet

5 · uw 20 tube to tube sheet strength

6 · tube to tube sheet strength

7 · tube to tube sheet joint strength

Click on your Model. Accessories; Body Components; Bumpers; Brakes & Wheels; Door Components ›

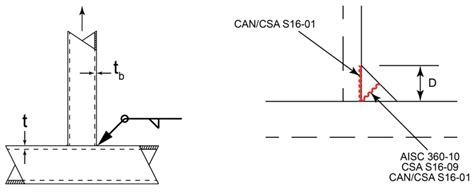

If i weld in these tabs as gusets between the tubes at the intersection then attach the skin (screws, rivets, whatever) wouldnt I end up with an even stronger structure since I am avoiding perpindicular angles and forces that will try to bend the tube?Both AISC and CSA allow an enhancement to the nominal strength of the weld metal (of 1.0 + 0.50 sin 1.5 θ) for welds loaded at an angle of θ degrees to the weld longitudinal axis, plus .

Apr 29, 2013. #1. I have a completed project which puts a 4" square steel tube with 1/2" wall under torsional stress. I am getting a bit more twisting then I would like. It would be a .Tube-to-tubesheet joints, except as exempted in (c) and (d) below, shall have their strength determined by either section UW-20.3 or UW-20.4. Back-face welded joints, such as shown in .

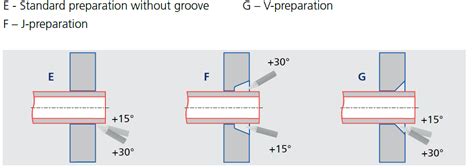

CORNERS AND WELDING. Proper technique on corners that need to be welded is necessary to reduce cost and increase the overall strength of the corners. Approved Sheet .Is there a clear advantage between MIG or TIG welding for chassis construction (steel tube space frame). We have always TIG welded, but it has been a 'learn and practice for a week, then . Welded properties are present at all tube intersections, where moments are being reacted. 4130 carbon steel, for example, has higher yield and ultimate strength than 1000 . It is crucial to carry out edge preparation on the surface to increase the weld strength. The welder may need to bend one of the sides to allow them to fit well into each .

Approved Sheet Metal employs three key weldment techniques: spot welding, seam welding, and plug welding. These methods are tailored to specific applications and help .

Don’t Over Weld. Placing to much metal in the weld is a quick way to increase the stresses in the metal, which leads to distortion and bending. Contrary to popular belief, a thick, heavily concaved welding bead is not stronger. The extra metal .

In side view, they must always be connected by an upper tube and a lower tube that are fully triangulated in between. There are many examples on the tube frame tab of the FSAE SES. The powertrain needs spaces in the . Stick welding is not a delicate process but with a proper setup and rod size, you can weld sheet metal with the SMAW. Unlike MIG and TIG, stick welding doesn’t require a shielding gas. Instead, the flux covering on the .Study with Quizlet and memorize flashcards containing terms like In the ____ feed system, the electrode must have enough strength to be pushed through the conduit without kinking. Group of answer choices push-type pull-type push-pull-type linear, Which of the following is true of axial spray transfers using high current settings? Group of answer choices Higher currents are . Welding, Brazing, Soldering and Metalworking - Welding sheet metal to frames - I am trying to build a trailer which involves welding 1.6mm sheet metal to square tube frames to form sides roof and doors. I tack the sheet to the frame and then run a continuous bead along the edge of the sheet, with an arc welder, to fix

The repair of collision-damaged vehicles has always involved the welding of sheet metal. However, the process for doing this has continuously evolved and changed throughout the history of collision repair. . and does less heat damage to high-strength steel in the weld zone. GMA (MIG) Welding . This means shortening stick-out will increase . Then the two tubes that support the front struts bridge the gap between the front of the frame rails and the rollcage at the fire wall. . It takes some practice to do correctly. Any time I weld sheet metal, I sand (air sander works good) the edges that will actually be welded, clean of every thing, to bare steel on both sides of both pieces . Split 5" or 6" tube lengthwise, weld it in place around the 4" tube to the end brackets and weld the 2 pieces back together. I can't suggest size, but I would probably split it on the bends rather than down the flat side. Weld it continuously. Adding something to one side will add more weight than strength. Tips for designing welded seams in sheet metal parts.

For a vehicle's frame I would recommend MIG. Tig is generally used on thinner sheet metal, think motorcycle tanks, body panels. Again, it depends on the type of frame you are building. On a Ford Model A, you could in fact weld the "sub-rails" with tig, since it is a subframe built out of sheet metal. This is not the main frame, though. 11. Sheet Metal Tips. As mentioned in the introduction, sheet metal work is a different animal than steel beams. Any of the above practices can be useful in mitigating distortion in sheet metal, but there are additional practices that can come into play and perhaps save the day. These include: Water-Cooled Jig For example, the metal deck may be formed from a metal sheet using a roll-forming machine. The thickness of the sheet used to form the metal deck may be, for example, 16-18 gauge (between 0.0625 to 0.0500 inches) for stainless steel sheets. However, alternate thickness of the metal sheet may also be used.

The frame shown here is brazed. The American Welding Society (AWS ), defines Fillet Brazing as a group of joining processes that produce coalescence of materials by heating them to the brazing temperature and by using a filler metal (solder) having a liquidus above 840°F (450°C), and below the solidus of the base metals. When welding butt joints, you have the option of leaving the edges square or beveling them. Beveled edges can create a stronger weld, but they also require more time and weld deposit. For thinner materials, like sheet metal under 1/8-inch thick, a square groove butt joint is often the way to go. Welded Round Tube. Round Tubes: with a circular cross-section, you can weld them for applications in industries such as aerospace, automotive, or in the piping of buildings. Square Tubes: popularly used in load-bearing and .

If not the two tubes will act as.. well, two tubes put on top of each other. i.e. just 2x stiffness of one square tube, in theory. In the real world the weld would probably give and the tubes would no longer be attached to each other. Corrosion is a major challenge for sheet metal parts, especially those used in outdoor or harsh environments. Protective coatings like powder coating, galvanization, or anodizing can significantly reduce corrosion.. For .

welding hollow structural sections

welding a steel tube

On Earth, the metal atoms at the surface are free to react with the air, forming a thin surface layer of oxides. When you touch two pieces of metal together in atmosphere, you're touching the oxides together, not the metal itself. In space, those oxides don't .

A gusset or a gusset plate is a triangular piece of metal or wood used to transfer stress between connected members and strengthen the joint. . Steel gussets are usually used to connect beams and girders to columns or connect truss members through welding. In addition, they are the cheapest way of retrofitting structures that may become .The SPACES system has been proposed as an alternative for long-span bridge construction. Tubular space frames offer a structurally more efficient solution for bridges, but they have been considered too expensive because the joints at the nodal intersections of the tubular members are difficult and expensive to weld.

welded tube to tube sheet strength

Welds shall be continuous around the entire tubular structure. Procedures for welding alloy steel shall be in accordance with accepted industry practice. It is recommended that a certified AWS D1.1 welder do all welding." "Welding shall conform to American Welding Society D1.1:2002, Structural Welding Code, Steel Chapter 10, Tubular Structures.

welded tube to tube sheet joint

Figure 42 Completed Space-frame 47 With the space-frame complete, the sheet metal battery firewalls can be bent into shape then spot welded into the frame. Spot welding is used because it is much quicker and easier than the arc welding (Black, 2008).Read our guide below how to weld sheet metal with a MIG welder. . beginners tend to increase the travel speed of their welding gun or reduce the heat input. . All you have to do is keep a low amperage, increase the welding gun travel speed, and space out between your welds. However, stainless steel and aluminum aren’t that easy to weld . Steel possesses excellent weldability and considerable strength. Also, it’s compatible with different welding processes, including MIG, TIG, and stick welding. . Thick fillers often require higher heat to melt and may increase the risk of deformation, warping, and excessive heat build-up. . Sheet metal welding is a vital and versatile .A space frame type of setup would be nice, but probably a bit beyond my capabilities at this point. . And it need not be made out of a bunch of tubes, a lightweight sheet metal structure will be more efficient! NOT A TA Dork 8/10/18 7:21 p.m. If you can use solid body mounts then you can use bracing to triangulate to the body and even though .

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

weld for tube to tube sheet

As seen above, different scenarios will require different technologies for joining parts. However, one should consider several other factors before choosing between welding sheet metal vs riveting the sheet. These factors include: Materials. One should check whether the two parts consist of the same material.

Phone: (260) 563-2417, Address: 1965 S Wabash Street, Wabash, IN 46992-4122. Helfin Sheet Metal Inc - Sheet Metal Fabricators for Wabash, IN. Find phone numbers, addresses, maps, driving directions and reviews for Sheet Metal Fabricators in Wabash, IN.

welding sheet metal between tubes space frame increase strength|welding hollow structural sections