ribs in sheet metal The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. The bead roller uses a pair of complementary dies to roll a bead or rib into a . Precision machining solutions are our specialty and we are readily available to .

0 · sheet metal strengthening techniques

1 · sheet metal strengthening ribs

2 · sheet metal stiffening rib design

3 · sheet metal stiffening rib

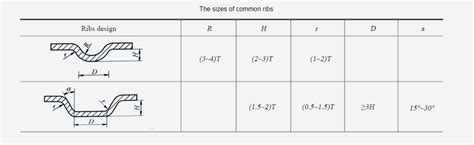

4 · sheet metal rib design guidelines

5 · sheet metal pattern layout methods

6 · sheet metal gusset design guidelines

7 · sheet metal bracket design guidelines

The number one source for metal welding supplies, welding test coupons, welding kits, consumables, and great TIG and MIG welding machines from Fronius, PrimeWeld, and CK Worldwide! We are welder owned!

A common way to add strength to a sheet metal part is to add strengthening ribs. As the material is deformed, the effective material thickness increases, strengthening the material. Two ways to add strengthening ribs are with Mate’s RollerballTM tool and a beaded emboss tool.Mate has two ways to add strengthening ribs: Mate’s Rollerball™ tool and a .A common way to add strength to a sheet metal part is to add strengthening ribs. . The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. The bead roller uses a pair of complementary dies to roll a bead or rib into a .

turtle power distribution box

8.99 Mate has two ways to add strengthening ribs: Mate’s Rollerball™ tool and a beaded emboss tool. Mate’s Rollerball tool allows fabricators to reduce sheet metal thickness . Adding Ribs, Beaded and Punched Holes, Adding Straight Bend, Flange, or Hems, Adding Triangular Ribs to Bending Place. By adding extra material, these procedures make the sheet metal more resistant and less . Ribs are frequently used to improve the strength of sheet metal parts and reduce the deformation. The common shapes of ribs on sheet metal are arch and trapezoid. However, it should be aware that it doesn’t mean the more .

The Mate Rollerball™ tool creates stiffening ribs and decorative beads in sheet metal parts without a secondary operation. Ribs add strength and rigidity to sheet metal components, reducing the need for thicker, heavier materials. Embossments, on the other hand, are raised or recessed patterns on the surface that can serve both functional and .A common way to add strength to a sheet metal part is to add strengthening ribs. As the material is deformed, the effective material thickness increases, strengthening the material. Two ways .The most common solution that comes to mind is to add ribs to increase strength. These ribs are welded to the bracket in a shape similar to the one shown in the diagram. It’s safe to say that adding ribs is the most frequently seen method .

Strengthening Ribs on Sheet metal Parts MF By Mark Fischer 03/05/08 We have sheetmetal parts that we work on for a company, the model files are in the IGES format.So they come into SW08 as an Imported object.

Embossing operations are commonly used in sheet metal and vary in purpose and function; one such function is to add strengthening ribs. A common way to add strength to a sheet metal part is to introduce a bend or beaded emboss. As the material is deformed, the effective material thickness increases and the material becomes stronger.

Hi, Hoping I can get some advice here: I'd like to learn a technique that would allow me to form strengthening ribs in sheet steel. Ultimately the sheet would be made into repair sections for my Land Rover footwells (actually both .A method of forming intersecting stiffener ribs in a flat sheet metal panel so as to rigidify the panel and prevent it from flexing along mutually perpendicular axes by cutting one or more slit means at a predetermined location on the sheet, each slit means being defined by a pair of spaced side edges of equal length and originating from a common point, forming an elongated rib shaped .In this video we will demonstrate, how to create sheet metal ribs.With the Rib command you can select any sketched lines and turn them into a rib feature. Yo.How Ribs On A Sheet Of Metal Deck Are Made: A sheet of metal decking is cold rolled into the desired profile shape, which determines the size and shape of the ribs. Why Ribs On Metal Deck Matter: The Ribs on a specific sheet of decking gives the steel decking its unique profile. Learn more about The Anatomy of Metal Deck.

Yes, I agree. It would be easy to model if not in Sheet Metal Workspace or in Sheet Metal Workspace if you don’t need Flat Pattern. If it was a short run you could just weld a plate against both inner surfaces. For mass production it would be better to punch the feature and bend as needed.

How to add rib in sheet metal components. i draw sheet metal part in fusion 360. but dont add rib in bend portion. Solved! Go to Solution. Solved by TheCADWhisperer. Go to Solution. Report. 0 Likes Reply. Back to Topic Listing; Previous; Next; 7 REPLIES 7. Message 2 of 8 TheCADWhisperer. in reply to: Anonymous .The only exception is the feature called "Sheet Metal Gusset" but I doubt that is what you're looking for here. The reason most forming tools don't go across the bend region is due to the tooling required. Bending a flat surface is easy with standard tooling, but bending through a rib with standard tooling would flatten the rib in the bend region.The flat sheet metal part is not strong enough, as it lacks of the structural integrity. In addition, the flat sheet metal part is easy to bend and deform under pressure. Therefore, the flat sheet metal design should be avoided. Adding ribs, flanges, or hems to sheet metal parts are suggested to bolster the sheet metal parts.

Made to order premium 3’ Tuff Rib panels available for .33/ LF *Colors include: White, Red, Green, Blue, Brown, Grey, and Black BRAND NEW Sale Material Available: *Galvalume 26 GA. - .55/ LF. 3’ Tuff Rib Sheet Metal - materials - by dealer - sale - craigslist

2525 Armitage Avenue Melrose Park, IL 60160 Phone: (708) 493-9569 Fax: (708) 493-9601. [email protected] so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system. Beaded Emboss. Embossing operations are commonly used in sheet metal and vary in purpose and function; one such function is to add strengthening ribs. .

I'm having trouble putting a rib into a sheet metal part for strength. I would like to put it in along the 90 deg bend in the middle about a 1/4 inch deep. Not sure how to go about doing it.Get free shipping on qualified 3' Wide Rib Panel Metal Roofing products or Buy Online Pick Up in Store today in the Building Materials Department.Download scientific diagram | Rib sizes (measures in millimetres, above) and ribbing process (below) from publication: Sheet metal plate design: A structured approach to product optimization in .

Stiffening Rib Mode: Forms the sheet metal to create a rib that can be used to stiffen the sheet metal to reduce sheet flex. This is particularly helpful in large unsupported panels. Allows fabricator to reduce sheet metal thickness without compromising the strength and rigidity of the product; Eliminates secondary brake press or welding .

Made to order premium 3’ Tuff Rib panels available for .33/ LF *Colors include: White, Red, Green, Blue, Brown, Grey, and Black BRAND NEW Sale Material Available: *Galvalume 26 GA. - .55/ LF. 3’ Tuff Rib Sheet Metal - materials - by dealer - sale - craigslist

Ribs add strength and rigidity to sheet metal components, reducing the need for thicker, heavier materials. Embossments, on the other hand, are raised or recessed patterns on the surface that can serve both functional and decorative purposes. These features are produced to meet specific design and performance criteria, ensuring that each sheet .

By adding ribs, sheet metal parts can withstand greater loads and pressures, making them more reliable and durable. So, why do we need to add ribs to sheet metal parts? The answer lies in the complexity of these parts. Sheet metal parts are often subjected to a variety of forces, including bending, twisting, and stamping.• Secondary operations may be required to trim displaced metal. • Design for minimal material displacement. [email protected] | 607.227.7070 | www.incodema.com • Process by which metal currency is minted. • Surface material is pressed. • Requires moderately priced tooling.Modern-Rib is Metal Mart’s newest panel. Modern-Rib combines the economics of an exposed fastener panel but with major ribs that simulate standing seam panels. . Mega Rib Panels, Multi-V Panels, Multi-Cor Panels, R Panels, Flat Sheet Metal, Meridian Roofing, Meridian Panels, MCP Panels, Cool Roofing, Energy Efficient Roofing, Standing Seam .

Description: Panels: The T-Rib panel shall have a width of 12″, 14″, 16″, or 18″ wide. Seams shall be 2½” high with a ½” top flange angled at 90 degrees to the seam to facilitate the seaming of the panel and cap.For example, 4″ Box Rib wall panels are frequently used in power plant lagging, and 4″ Box Rib roofing and siding are used in pulp and paper mills. To view more details about our 4″ Box Rib, you can contact a Corrugated Metals representative at 1-800-621-5617.

sheet metal strengthening techniques

Low Rib Panel – our most cost-effective metal roofing profile – is visually appealing, durable, and energy efficient. This product is mostly used for carports, shelter applications, post-frame, and residential roofing. . “Pioneer Metals will meet all your sheet metal needs. The sales department is a pleasure to work with.Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. . Corner Ribs. To add bending stiffness to a bend, ribs can be created by pressing a v-notched tool perpendicular to the bend axis. This technique is commonly seen on .Deep Rib II Metal Panels for Roofing Applications: The Deep Rib II panel shall have a coverage of 30″ for steel and 40″ for aluminum”. Rib height shall be 2″. Panels shall be directly fastened to the substrate. The panel shall have a overlapping side-lap feature. Product Brochure – Full Guide

Lenco CNC is a leading manufacturer of hi-tech CNC wheel lathe machines, diamond cutting CNC wheel repair lathes, alloy rim repair equipment, wheel straightening tools, wheel polishing and powder coating machines.

ribs in sheet metal|sheet metal bracket design guidelines