cnc lathe machine life expectancy Generally speaking you can expect a CNC machine to last 15-20 years, but with proper care and maintenance a CNC machine could see a lifespan of over 30 years. As with all machines, a . An explosion-proof junction box is a specialized electrical enclosure designed to protect electrical connections and components in hazardous environments where there is a risk of explosion.

0 · life expectancy of used machine

1 · life expectancy of a lathe

2 · how long can a cnc machine last

3 · haas lathe life expectancy

4 · cnc machine life expectancy

5 · 2000 hour lathe life expectancy

What is CNC Bending Machine? A CNC bending machine is a type of computer-controlled machine used to bend and shape metal sheets and tubes into various shapes and forms. It is an advanced form of a press brake machine that uses CNC technology to accurately control the bending process and get more consistent and precise bends.

If a machine gets reasonable maintenance (regular lubrication/cleaning) and isn't abused (hogging hardened steel) what kinds of hours of operation can be expected from them? Let's say this is for good quality mid-range machines and also high-end (like the Hardinge .In this blog post, we will delve into the factors that influence the life expectancy of CNC machines, discuss maintenance practices to prolong their lifespan, and provide tips for maximizing their .

Generally speaking you can expect a CNC machine to last 15-20 years, but with proper care and maintenance a CNC machine could see a lifespan of over 30 years. As with all machines, a . The lifespan of a CNC machine depends on several factors, including the type and quality of the machine, how often it’s used, and how well it’s maintained. On average, a well-maintained CNC machine can last for 10 .In summary, the life expectancy of a CNC machine varies based on factors such as type, usage intensity, and maintenance. Generally, with proper care and regular maintenance, CNC .

Discover how long a lathe machine typically lasts and the factors that influence its lifespan. Learn essential maintenance tips to extend the life of your lathe and know when it might be time for a .The lifespan of a CNC machine depends in large part on the type of machine. For instance, a complex CNC lathe may have a service life of about 20 years, while a basic CNC milling .

To put it simply, predictive maintenance has proven to be a significant game changer for the longevity of CNC machines and manufacturing equipment. This article details exactly how this has been achieved. What is .

Specifically, if a well-built machine, e.g. a mainstream Japanese HMC or lathe, runs 6000-8000 hours per year under moderate cutting conditions (mid-range RPM , spindle . If a machine gets reasonable maintenance (regular lubrication/cleaning) and isn't abused (hogging hardened steel) what kinds of hours of operation can be expected from them? Let's say this is for good quality mid-range machines and also high-end (like the Hardinge toolroom lathe?).In this blog post, we will delve into the factors that influence the life expectancy of CNC machines, discuss maintenance practices to prolong their lifespan, and provide tips for maximizing their efficiency.

Generally speaking you can expect a CNC machine to last 15-20 years, but with proper care and maintenance a CNC machine could see a lifespan of over 30 years. As with all machines, a CNC machine’s lifespan is impacted by many factors.

The lifespan of a CNC machine depends on several factors, including the type and quality of the machine, how often it’s used, and how well it’s maintained. On average, a well-maintained CNC machine can last for 10-15 years, or even longer in some cases.In summary, the life expectancy of a CNC machine varies based on factors such as type, usage intensity, and maintenance. Generally, with proper care and regular maintenance, CNC machines can have a lifespan of 15 to 25 years.Discover how long a lathe machine typically lasts and the factors that influence its lifespan. Learn essential maintenance tips to extend the life of your lathe and know when it might be time for a replacement. This guide will help you maximize your investment and ensure your lathe's longevity.The lifespan of a CNC machine depends in large part on the type of machine. For instance, a complex CNC lathe may have a service life of about 20 years, while a basic CNC milling machine may be of service for about 10 to 15 years. Quality of the CNC Machine. The quality of the machine will contribute to the length of its service life.

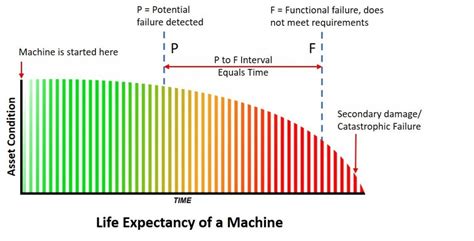

To put it simply, predictive maintenance has proven to be a significant game changer for the longevity of CNC machines and manufacturing equipment. This article details exactly how this has been achieved. What is Predictive Maintenance? 1. Reduced Cases of Breakdowns. 2. Decreased Downtime. 3. Better Planning. 4. Improved Productivity. 5.

Specifically, if a well-built machine, e.g. a mainstream Japanese HMC or lathe, runs 6000-8000 hours per year under moderate cutting conditions (mid-range RPM , spindle load, rapids, etc) without any serious bumps, how long will it . In the near future I will be looking for a 4 Axis CNC milling machine and a 2 Axis CNC lathe. Both will need to have repeatable accuracy in chromoly stainless steel and Titanium. If a machine gets reasonable maintenance (regular lubrication/cleaning) and isn't abused (hogging hardened steel) what kinds of hours of operation can be expected from them? Let's say this is for good quality mid-range machines and also high-end (like the Hardinge toolroom lathe?).

In this blog post, we will delve into the factors that influence the life expectancy of CNC machines, discuss maintenance practices to prolong their lifespan, and provide tips for maximizing their efficiency.

Generally speaking you can expect a CNC machine to last 15-20 years, but with proper care and maintenance a CNC machine could see a lifespan of over 30 years. As with all machines, a CNC machine’s lifespan is impacted by many factors.

The lifespan of a CNC machine depends on several factors, including the type and quality of the machine, how often it’s used, and how well it’s maintained. On average, a well-maintained CNC machine can last for 10-15 years, or even longer in some cases.In summary, the life expectancy of a CNC machine varies based on factors such as type, usage intensity, and maintenance. Generally, with proper care and regular maintenance, CNC machines can have a lifespan of 15 to 25 years.Discover how long a lathe machine typically lasts and the factors that influence its lifespan. Learn essential maintenance tips to extend the life of your lathe and know when it might be time for a replacement. This guide will help you maximize your investment and ensure your lathe's longevity.

The lifespan of a CNC machine depends in large part on the type of machine. For instance, a complex CNC lathe may have a service life of about 20 years, while a basic CNC milling machine may be of service for about 10 to 15 years. Quality of the CNC Machine. The quality of the machine will contribute to the length of its service life. To put it simply, predictive maintenance has proven to be a significant game changer for the longevity of CNC machines and manufacturing equipment. This article details exactly how this has been achieved. What is Predictive Maintenance? 1. Reduced Cases of Breakdowns. 2. Decreased Downtime. 3. Better Planning. 4. Improved Productivity. 5. Specifically, if a well-built machine, e.g. a mainstream Japanese HMC or lathe, runs 6000-8000 hours per year under moderate cutting conditions (mid-range RPM , spindle load, rapids, etc) without any serious bumps, how long will it .

life expectancy of used machine

fima metal box

find details electrical panel box

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers.

cnc lathe machine life expectancy|2000 hour lathe life expectancy