abs cnc machining Rally's ABS CNC machining offers advanced solutions for durable, precise components. Explore benefits, applications, and industry insights. Discover the edge in cycling with our guide on CNC Machined Bike Parts.

• KIT INCLUDES: Pre-assembled 2-drawer metal cabinet with hardware, stainless steel sink, strainer, and fully adjustable high arc Flex+Freeze faucet • MULTI-PURPOSE: UV-resistant and suitable for indoor or outdoor use, making it the ideal sink for any space - the garage, office, utility set-up, mudroom, hobby room, indoor or outdoor bar .

0 · plastic precision machining

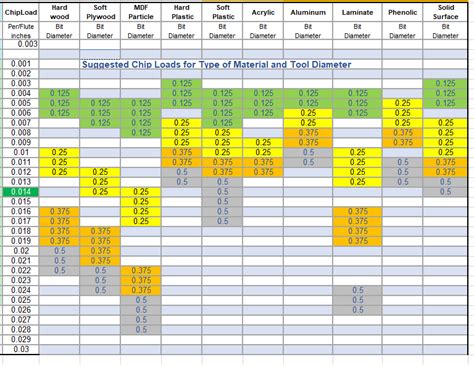

1 · machining abs plastic

2 · machining abs feeds and speeds

3 · feeds and speeds for abs

4 · abs plastic blocks for machining

5 · abs machining mississauga

6 · abs machining canada

7 · abs blocks for machining

Best Metal Fabricators in Western North Carolina, NC - Black Mountain Ironworks, Ray's Fabricating, McGee Brothers Machine & Welding, Pleasant Gardens Machine, Superior Welding & Repair, PowderTek, Skyline Metal Worx, Chambers Auto & Fab, Avtech Inc, OAK HILL IRON + .

ABS CNC machining provides a versatile solution for creating durable, high-quality parts and products. CNC-machined ABS parts are used in almost everything from protective .The CNC machining defects refer to any undesirable results and failure in . CNC machining, a computer-controlled subtractive manufacturing process, offers a precise and efficient method for producing ABS parts. However, machining ABS plastic requires specific considerations to achieve optimal results. Acrylonitrile butadiene styrene (ABS) is a low-cost engineering thermoplastic due to its good dimensional stability, excellent impact strength and ease of machining. ABS is often used for prototyping because it is easy to .

Although ABS can be processed into finished parts with various methods, CNC machining of ABS offers various benefits, including precision, customization, and production .Rally's ABS CNC machining offers advanced solutions for durable, precise components. Explore benefits, applications, and industry insights. Discover the edge in cycling with our guide on CNC Machined Bike Parts.

ABS CNC machining provides a versatile solution for creating durable, high-quality parts and products. CNC-machined ABS parts are used in almost everything from protective headgear to musical instruments because they can be . CNC machining, a computer-controlled subtractive manufacturing process, offers a precise and efficient method for producing ABS parts. However, machining ABS plastic requires specific considerations to achieve optimal results.

Acrylonitrile butadiene styrene (ABS) is a low-cost engineering thermoplastic due to its good dimensional stability, excellent impact strength and ease of machining. ABS is often used for prototyping because it is easy to CNC machine . Although it is often blow molded, ABS can be CNC machined and milled for precision parts. ABS is manufactured in a variety of grades, but for precision machining of ABS structural parts, it is recommended to use Machine Grade ABS. Although ABS can be processed into finished parts with various methods, CNC machining of ABS offers various benefits, including precision, customization, and production flexibility. The machining processes can produce ABS-machined components of different shapes, sizes, and features.

Rally's ABS CNC machining offers advanced solutions for durable, precise components. Explore benefits, applications, and industry insights. Discover the edge in cycling with our guide on CNC Machined Bike Parts.CNC machining of ABS plastic offers unrivalled precision, durability and cost-effectiveness, making it ideal for a wide range of applications, from prototyping to manufacturing end parts. Its versatile nature ensures high-quality results and consistent . Manufacturers rely on ABS CNC machining to produce top-quality, precise ABS parts with tight tolerances. This article discusses ABS plastic and the benefits and setbacks of CNC machining ABS plastic. Continue reading to learn about typical ABS parts applications and expert tips for effective machining!

North America's global supplier of USA CNC Machining services to industry leading OEM’s. ABS Machining established in 1971 has a proven track record of success delivering quality precision machined parts, fabrications and assemblies for the most demanding projects. This article aims to provide a comprehensive guide to the precision machining of ABS plastics, including machining methods, tool selection, machining parameters, and troubleshooting tips, to help readers better understand and .

ABS CNC machining provides a versatile solution for creating durable, high-quality parts and products. CNC-machined ABS parts are used in almost everything from protective headgear to musical instruments because they can be .

CNC machining, a computer-controlled subtractive manufacturing process, offers a precise and efficient method for producing ABS parts. However, machining ABS plastic requires specific considerations to achieve optimal results. Acrylonitrile butadiene styrene (ABS) is a low-cost engineering thermoplastic due to its good dimensional stability, excellent impact strength and ease of machining. ABS is often used for prototyping because it is easy to CNC machine . Although it is often blow molded, ABS can be CNC machined and milled for precision parts. ABS is manufactured in a variety of grades, but for precision machining of ABS structural parts, it is recommended to use Machine Grade ABS.

plastic precision machining

Although ABS can be processed into finished parts with various methods, CNC machining of ABS offers various benefits, including precision, customization, and production flexibility. The machining processes can produce ABS-machined components of different shapes, sizes, and features.

Rally's ABS CNC machining offers advanced solutions for durable, precise components. Explore benefits, applications, and industry insights. Discover the edge in cycling with our guide on CNC Machined Bike Parts.CNC machining of ABS plastic offers unrivalled precision, durability and cost-effectiveness, making it ideal for a wide range of applications, from prototyping to manufacturing end parts. Its versatile nature ensures high-quality results and consistent . Manufacturers rely on ABS CNC machining to produce top-quality, precise ABS parts with tight tolerances. This article discusses ABS plastic and the benefits and setbacks of CNC machining ABS plastic. Continue reading to learn about typical ABS parts applications and expert tips for effective machining!

North America's global supplier of USA CNC Machining services to industry leading OEM’s. ABS Machining established in 1971 has a proven track record of success delivering quality precision machined parts, fabrications and assemblies for the most demanding projects.

machining abs plastic

1. Start with raw plywood edges that are straight cut and clean, no sawdust to prevent adhesion. 2. Cut the edge banding to about 1/2" longer than the overall length needed. 3. Apply the edge banding to the plywood edge using a hot iron, working with the iron in your right hand, working right to left.

abs cnc machining|feeds and speeds for abs