sheet metal bend stiffener When you bend sheet metal in a press brake, the resulting bend doesn’t form a perfect 90-degree angle. Instead, the tool has a rounded tip that adds a radius to the bend. If you measure the length of that bent area and divide it by two, . It is essential to choose the right MIG electrode and wire for perfect sheet metal welding. We suggest you select the wire with the smallest diameter. Since the wire has less diameter, it also takes less heat. Hence, with less space, the wire will burn or melt the least space on the sheet.Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here. See more

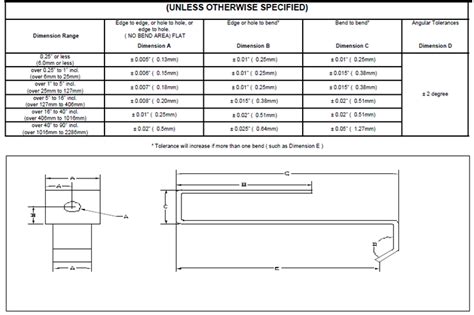

0 · standard sheet metal tolerances

1 · sheet metal relief cuts

2 · sheet metal gusset design guidelines

3 · sheet metal fabrication design guide

4 · sheet metal design calculations

5 · sheet metal bend relief guidelines

6 · minimum bend radius sheet metal

7 · bend relief in sheet metal

Welding thin sheet metal is a challenge for any welder, but it can be even more daunting as an entry-level amateur or as a seasoned professional. For novices and experts alike, the key to successful welding of thin sheet .

A few methods are shown to stiffen up projects in sheet metal. Show more.

For sheet metal parts to be durable and reliable, metal strengthening, sometimes referred to as stiffening, is essential. It entails incorporating structural support to stop pieces from warping and failing under .

3.1.2. Stiffeners The metal sheets matter of the study can have stiffeners, either in the webs, in the crest or in both of them. Stiffeners are nothing more than a fold in the surface of the crest or the web. These stiffeners act as a partial support, allowing a wider effective width in the webs or crest along the stiffeners.When you bend sheet metal in a press brake, the resulting bend doesn’t form a perfect 90-degree angle. Instead, the tool has a rounded tip that adds a radius to the bend. If you measure the length of that bent area and divide it by two, .The process of stiffening sheet metal--known as cross braking--places a small bend across flat sections of metal. Each bend reduces the flat area of each side, increasing its overall strength. Increase the gap between the top and bottom dies of sheet metal brake by either pushing the clamping leaf handle away from the front of the brake or . The flat sheet metal part is not strong enough, as it lacks of the structural integrity. In addition, the flat sheet metal part is easy to bend and deform under pressure. Therefore, the flat sheet metal design should be avoided. Adding ribs, flanges, or hems to sheet metal parts are suggested to bolster the sheet metal parts.

standard sheet metal tolerances

In this video tutorial I will show you how to create sheet metal corner brace with stiffener in Part Design Workbench in open source software FreeCADJoin to .

You are sometimes faced with creating a cutout in sheet metal through multiple thicknesses and bends. Normally you would Unfold the sheet metal body, sketch.The use of stiffened panels has been widely developed in the industry.These aluminium panels consist of a sheet, the so-called skin, and stiffeners. These stiffeners have the advantage of considerably increasing the bending or buckling stiffness of these aluminium sheets.Due to the mechanical characteristics of these panels, riveting or MIG welding were for a long time the .

Good sheet metal design should reduce, simplify, and mistakeproof shop floor processes to ensure greater efficiency and, ultimately, dramatic cost reductions. In other words, manufacturing should be as easy as possible. If, say, a new design eliminates welding but makes the bending process incredibly complex, the process is moving backward.Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in sheet metal are manufactured using sheet metal brakes. A +/- 1 degree tolerance on all bend angles.

sheet metal relief cuts

Bending. A flat sheet metal is surely not very strong, but it can be grown stronger by the bending process. Bending helps in providing more strength to it, although there is something that should be remembered. Bending could result in cracks on the outer surface and here comes a concept of ‘bending radius’. Bending radius is the minimum .

A cross break is a shallow bend, corner-to-corner on a square or rectangular sheet metal panel. It's used as a stiffener. They are common items for duct work and enclosure panels. [green]"But what. is it good for?"[/green] Engineer at the Advanced Computing Systems Division of IBM, 1968, commenting on the microchip. Add stiffeners. If you want to keep your sheet metal component completely flat and it’s over 24”, you’ll need to spot weld, rivet on, or bolt on stiffeners across that length. Stiffeners fasten onto flat panels and add dimension and rigidity, making the flat panel sturdier so that it won’t bend or bow in the middle. Columnist Gerald Davis continues a discussion of 3-D CAD and precision sheet metal manufacturing in Part IV of a four-part series. In this installment he focuses on the merits and demerits of hems, jogs, and forming tools. . Also override the bend angle and set it to a value less than 90 degrees. A jog’s internal angle at 80 degrees is . Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting.

sheet metal gusset design guidelines

The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. The bead roller uses a pair of complementary dies to roll a bead or rib into a sheet metal panel Shrinking and Stretching . This is an education channel for all Engineers who enthusiast with 3D CAD, CAE, and CAM. Thank you for your kindly appreciation and please Subscribe.

They discovered the cost was less than the mill galvanized sheet and they were able to weld the pieces together. The stiffner could then be welded onto the aluminum sheet. If mill galvanized sheet is the only way to go, consider bending an "L" or "U" at the midspan of two sheet and bolt them together. Sheet metal with stiffeners: Bending sheet metal with pre-existing stiffeners or ribs works well with compression bending. 6. Stretch Forming. This technique is used to create complex shapes in sheet metal by stretching it over a mould. Stretch forming is a good option for creating aerodynamic shapes, such as those used in aircrafts.

Most frequently, expensive sheet metal bending tools, called brakes, are used to bend sheet metal, but you can also complete this task without one. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

The Mate Rollerball™ tool creates stiffening ribs and decorative beads in sheet metal parts without a secondary operation. It is available in popular tool st.A Rollformer uses a series of rolls to bend a long strip of sheet metal into a desired cross-section allowing for a wide variety of profiles to be produced. 3991 Green Park Rd. St. Louis, MO 63125 [email protected] 314.894.3903Once mounted, the stiffeners must not leave any marks or prevent the sheet metal from appearing taut. The stiffener is made of cardboard or plastic sheets – on purpose to maintain the objective of weight reduction. This material may be combined with an acoustic damping plate (Fusible Sound Absorber Sheet, IFF), to combat vibration phenomena. Precision sheet metal bending is one of our many high quality machining and manufacturing services here at SendCutSend. With some CNC magic, your 2D sheet metal part can transform into a 3D part in a matter of seconds. This is valuable for many applications: mounting brackets, suspension mounts, battery boxes, and other components that need to .

Today, we’re mostly concerned with sheet metal structures, particularly aluminum, with stiffeners lined up in the direction of the load. If you’re building in wood, you should see ANC-18, Design of Wood Aircraft Structures for design information. If you’re building in composites, chances are you wouldn’t use local stiffeners anyway, and if you did, they’d be shaped .Reduction of steel sheet thickness as a means of reducing vehicle weight may necessitate some method of enhancing flexural stiffness. Three basic types of sheet stiffening methods have been investigated: integrally formed rib stiffeners, foam-backed sheets and .Download your free 30-day BricsCAD trial on https://www.bricsys.com/mechanical-----In some cases, non-orthogonal connections of f. Chapter #6 – Sheet Metal Joints Rectangular Duct Joints TDC – Transverse Duct Connector (SMACNA T-25A) This traverse duct connector is fabricated from the same piece of metal as the duct (#3), and has a gasket (#10) inserted between the two joints of duct or fitting and is locked in place by a cleat (#9).

sheet metal fabrication design guide

sheet metal design calculations

sheet metal bend relief guidelines

As you know, when welding there is a lot of heat. But what you might not know is that if there's too much heat on a metal part it can actually cause it to di.

sheet metal bend stiffener|sheet metal bend relief guidelines