sheet metal bends Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

Pull boxes are used in conduit lines when outlet bends exceed the National Electric Code’s maximum number. The specific size of the pull box depends on the size and the number of conductors. In addition, the diameter .

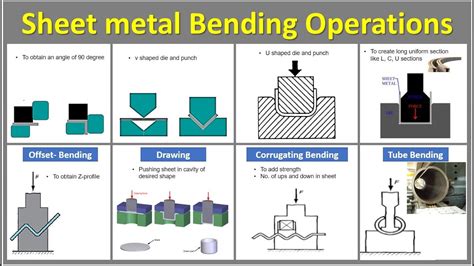

0 · types of sheet metal bends

1 · types of sheet metal benders

2 · sheet metal bending dies

3 · sheet metal bend tolerance chart

4 · sheet metal bend allowance chart

5 · maximum thickness sheet metal bending

6 · bend sheet metal at home

7 · bend allowance in sheet metal

Machines such as CNC grinders, CNC lathes, and CNC turning mills are all integrated into CNC manufacturing. CNC machines run automated from pre-programmed software and code to fabricate incredibly precise parts. A computer program directs the motion and production done by these machines.

Three-Station Edge Roller Bender,0-90° Bending Angle Bending Metal Roofing Materials,Adjustable for Making 5/8" to 4" (16 to 102 MM) Bends in 29 to 22-Gauge Steel,Large Sheet Metal Bender - Amazon.com

metallic accesnts in fabric

JEGS 555-81524 Sheet Metal Bending Brake. JEGS Bending Brake allows you to easily bend materials as heavy as 17-gauge steel with a maximum bend angle of 90 degrees. It has two handles on the front plate of the brake so you can easily lift the plate and force the material that is extended over a straight edge to create your desired bend.Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to .Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .

I'm working on a sheet metal part, but where a bend will work or won't work is a complete mystery to me. It's been a few weeks, but I haven't yet gotten the hang of it. I've scoured the forums and all over the internet for clues- including the wiki.. If I need to bend a simple rectangular plate- it works, any shape slightly more complicated is . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision and efficiency. We also pride ourselves on our ability to deliver custom metal parts quickly and efficiently, often on the same day.

The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part stretches.

4 Sheet Metal Bend Gains FAQ. 4.0.1 What is a sheet metal bend gain, and why is it important in sheet metal fabrication? 4.0.2 Why should design engineers be concerned about sheet metal bend gains? 4.0.3 Do design engineers need to calculate sheet metal bend gains themselves? 4.0.4 How can I accurately calculate sheet metal bend allowances or .

When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) .

Add a double bend to a sheet metal face. On the ribbon, click Sheet Metal tab Create panel Bend. Select a model edge on each sheet metal face. Enter a Bend Radius if it is different from the default for the part. Click the down arrow to select Measure, Show Dimensions, or List Parameters to enter a different value. Most frequently, expensive sheet metal bending tools, called brakes, are used to bend sheet metal, but you can also complete this task without one. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. How do precise Z-bends and N-bends transform flat sheet metal into complex shapes? This article dives into the essential techniques and precautions for Z and N bending in sheet metal fabrication. You’ll learn about critical procedures, positioning principles, and special processing methods to ensure accurate and efficient results in your .

Hand Seamer, 6in Straight Jaw Sheet Metal Bender Tools, Sheet Metal Seamer Form Edge Seamer Seaming Plier with Ergonomic Handle, for Bending and Flattening Sheet Metal Hand Tool. 4.5 out of 5 stars. 85. 200+ bought in past month. .99 $ 20. 99. FREE delivery Sun, Oct 27 on of items shipped by Amazon.Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.

When you mirror a sheet metal part, many of the bends are mirrored as well. Click Back (Heads-up View toolbar).; Zoom to the right corner of the model's back face. Click Mirror (Features tab).; Select one of the back planar faces, as shown, for Mirror Face/Plane. The Eastwood Versa Bend 20 Inch Offset Sheet Metal Brake is a precision engineered metal working tool designed to produce both standard variable length bends as well as accurate 1/2 Inch offset bends up to 90 Degrees in 20 gauge sheet steel and 18 gauge aluminum in widths up to 20 Inch. How sheet metal bends, k factor, bend allowance explained and more. This video includes drawings, animations, formulas and press brake bends.More On K Facto.The Klein Tools Offset Hand Seamer makes working in confined spaces easy with the compound-leverage mechanism and convenient self-opening latch. The 3 inch steel jaw is notched in 1/4-Inch increments for accurate sheet metal bending measurements. Comfortable, contoured grips cover durable, all-steel construction for long life and durability.

5. Sheet Metal Bending Collisions. Whether it’s an asteroid, a motor vehicle, or a sheet metal part, collisions really aren’t a good thing. In the world of bending, a collision occurs when the material to be bent contacts any surface other than the dies.

Understanding the Sheet Metal Bending Process. Sheet metal bending is an important process used in industries. It consists of the deformation of sheet metal at a certain angle or shape. Normally, this process uses tools like press brakes, bending machines, or whatever appropriate tools are available. Check out the straightforward explanation of .

types of sheet metal bends

Ironton Portable Sheet Metal Bending Brake, 30in. Wide. Item # 101452. .99 . Shipping: Available now See Shipping Options. Store Pickup: Check Store Stock. Add to Cart. Activating this checkbox will add this item to the product comparison tool. Compare Save to List. Shop Fox 3-in-1 Combination Sheet Metal Machine, 12in., Model# M1052.Top 10 Best Sheet Metal Fabricators in Bend, OR - November 2024 - Yelp - JC Precision Welding, Bend Heating & Sheet Metal, CLS Fabrication, J Bar Metal Fabrication, Advanced Northwest Welding, Simply Fabricated, Bend Machine, Harmon Seamless Gutter, Jon Small Welding, Bend Metal Fabrication Make Bend: 3rd step to convert a shell object into an unfoldable sheet metal object, replaces sharp edges with round bends. Sketch On Sheet metal: Cuts a sketch based hole pattern along the folded walls of a sheet metal object. Make Forming in Wall: Embosses shapes with or without holes into a sheet metal plate.

Sheet metal bending is a manufacturing process that deforms flat metal sheets into desired shapes with force. The process uses tools like punches and dies. Commonly, laser-cut sheet metals are bent using press brakes or benders. What is the difference between air bending and bottom bending? Table of Contents. 1 At Approved Sheet Metal, we’re happy to share our secret for creating offset bends using the standard tooling most sheet metal shops like ours already have. Why? Because being the BEST is about always finding ways to help our customers succeed. 2 Sheet Metal Part Design for Manufacturing Tip. 2.1 OFFSETS; 3 How to Create Sheet Metal .Designed for bends on flashing, roofing details, standing seam and exposed fastener metal roofing, these benders are as versatile as you can get. Easily adjust the rollers to handle different thicknesses and materials, all without scratching material on 90-degree bends with Malco’s exclusive angled roller.

types of sheet metal benders

catch basin has an opening (like a grate) to allow water in, the ground is sloped to the catch basin to direct water into it. a manhole is usually a solid cover, it's there to provide access to the drainage system or as the cover to a junction box between drainage pipes.

sheet metal bends|types of sheet metal benders