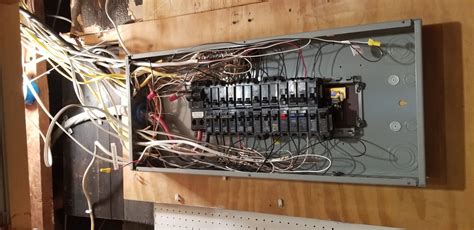

can i polish electrical terminals in a breaker box You can either replace or try to clean the breaker contacts also, then use some electrical grease to coat both the bus bar and the breaker contact. Not too much, just enough. Make sure you stay away from where the main feed comes in the box.. Our Waterproof Junction Box is constructed with premium waterproof materials and a sealed structure, effectively preventing the ingress of water, dust, and other contaminants, ensuring the reliability and safety of electrical connections.

0 · oxgaurd breaker box repair

1 · oxgaurd breaker box cleaning

2 · bus bar panel box cleaning

Sigma's weatherproof closure plugs help keep moisture from the electrical wiring by closing unused holes in weatherproof boxes, extension rings or covers. In a world that runs largely on electricity, junction boxes are crucial to protecting electrical wiring systems.

You can either replace or try to clean the breaker contacts also, then use some electrical grease to coat both the bus bar and the breaker contact. Not too much, just enough. Make sure you stay away from where the main feed comes in the box.. Paint can interfere with proper connections between electric components or proper operation of circuit breakers, creating conditions where proper grounding and electrical connections are not present, possibly causing .

Is using noalox safe to put on breaker electrical connections, yes. It’s not only safe but most manufacturers put their custom blend on the plug in part of the breaker and it is recommended for all aluminum parts. how i clean and use oxgaurd to prevent damage to a breaker box that started to corrode this may not be a solution consult with certified electrician before d.To improve the connection quality of an electrical contact or switch, you can remove oxidation or rust either mechanically and/or chemically. A brass or steel brush is the most common method of scrubbing off oxidation, although for . Your best bet is to plug the hole with something. Your choices are a panel hole cover UL listed for that panel, though those can be hokey and hard to find; or a spare Siemens/ITE breaker, labeled "Unused", under .

Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, .

The first is a cleaner for electrical connectors, which removes existing corrosion. This is done by some aggressive ingredients, which later will lead even more corrosion. (Like vinegar: can be used to remove rust, but also .

It's likely dielectric grease.it helps to keep oxygen out of the contact that can cause corrosion.it's not a bad thing to have on any electrical contact.leave it there. Yes, that aluminum wire can cause this corrosion if antioxidant is not used when installed. It does look like water has been in there as well at some time. I recommend a GFCI receptacle so, if it trips, you are right there to reset. . You can either replace or try to clean the breaker contacts also, then use some electrical grease to coat both the bus bar and the breaker contact. Not too much, just enough. Make sure you stay away from where the main feed comes in the box..

Paint can interfere with proper connections between electric components or proper operation of circuit breakers, creating conditions where proper grounding and electrical connections are not present, possibly causing brown-outs, arcing, and fires. Paint can also cause the wire insulation to deteriorate. Is using noalox safe to put on breaker electrical connections, yes. It’s not only safe but most manufacturers put their custom blend on the plug in part of the breaker and it is recommended for all aluminum parts.

how i clean and use oxgaurd to prevent damage to a breaker box that started to corrode this may not be a solution consult with certified electrician before d.

To improve the connection quality of an electrical contact or switch, you can remove oxidation or rust either mechanically and/or chemically. A brass or steel brush is the most common method of scrubbing off oxidation, although for sensitive contacts nylon is also used. Your best bet is to plug the hole with something. Your choices are a panel hole cover UL listed for that panel, though those can be hokey and hard to find; or a spare Siemens/ITE breaker, labeled "Unused", under .

Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit. This will overheat the wires and possibly start a fire. The first is a cleaner for electrical connectors, which removes existing corrosion. This is done by some aggressive ingredients, which later will lead even more corrosion. (Like vinegar: can be used to remove rust, but also causes rust) The second product is used after to protect the now clean contacts from further corrosion.

It's likely dielectric grease.it helps to keep oxygen out of the contact that can cause corrosion.it's not a bad thing to have on any electrical contact.leave it there. Yes, that aluminum wire can cause this corrosion if antioxidant is not used when installed. It does look like water has been in there as well at some time. I recommend a GFCI receptacle so, if it trips, you are right there to reset. No trip to the panel.

oxgaurd breaker box repair

You can either replace or try to clean the breaker contacts also, then use some electrical grease to coat both the bus bar and the breaker contact. Not too much, just enough. Make sure you stay away from where the main feed comes in the box.. Paint can interfere with proper connections between electric components or proper operation of circuit breakers, creating conditions where proper grounding and electrical connections are not present, possibly causing brown-outs, arcing, and fires. Paint can also cause the wire insulation to deteriorate. Is using noalox safe to put on breaker electrical connections, yes. It’s not only safe but most manufacturers put their custom blend on the plug in part of the breaker and it is recommended for all aluminum parts. how i clean and use oxgaurd to prevent damage to a breaker box that started to corrode this may not be a solution consult with certified electrician before d.

To improve the connection quality of an electrical contact or switch, you can remove oxidation or rust either mechanically and/or chemically. A brass or steel brush is the most common method of scrubbing off oxidation, although for sensitive contacts nylon is also used. Your best bet is to plug the hole with something. Your choices are a panel hole cover UL listed for that panel, though those can be hokey and hard to find; or a spare Siemens/ITE breaker, labeled "Unused", under . Corrosion at interior components of an electrical panel creates several safety problems: 1) Circuit breakers are mechanical devices and, like any mechanical device, corrosion can cause it to freeze up and not trip when too much current is flowing in the circuit. This will overheat the wires and possibly start a fire. The first is a cleaner for electrical connectors, which removes existing corrosion. This is done by some aggressive ingredients, which later will lead even more corrosion. (Like vinegar: can be used to remove rust, but also causes rust) The second product is used after to protect the now clean contacts from further corrosion.

It's likely dielectric grease.it helps to keep oxygen out of the contact that can cause corrosion.it's not a bad thing to have on any electrical contact.leave it there.

tulip metallic fabric paint review

turn best metal shed into house

Shop durable plastic or aluminum IP68 enclosures for protection in wet and dirty environments. Protect electronics with waterproof IP68 junction boxes!

can i polish electrical terminals in a breaker box|bus bar panel box cleaning