cert 3 heavy metal fabrication Start your career in engineering and fabrication with the nationally accredited Certificate III in Engineering - Fabrication Trade. This hands-on course is designed for apprentice . CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products.

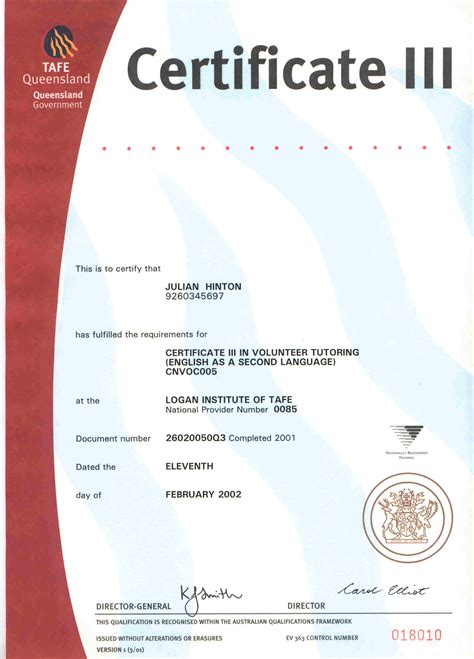

0 · tafe certificate 3

1 · fabrication training courses

2 · fabrication trade course

3 · fabrication trade certification fees

4 · fabrication trade certification

5 · fabrication trade certificate australia

6 · fabrication certificate 3

7 · cert 3 in engineering

“G” stands for Geometry; hence, the G-Code commands are responsible for the movements of the machine that create the geometry of the part. “M” stands for Machine (or Miscellaneous), and the M-Codes are responsible for Machine commands .

Forge a career in heavy metal fabrication. Our heavy fabrication apprenticeship course will teach you to safely manipulate metal and create objects using a variety of welding techniques, thermal cutting, workshop machines, and hand .Start your career in engineering and fabrication with the nationally accredited Certificate III in Engineering - Fabrication Trade. This hands-on course is designed for apprentice .

You’ll learn to make and repair steel and other metal products and structures such as boilers and storage tanks, and develop industry-specific skills including: arc welding; metal fabrication; forming and shaping techniques; forging and .In the Certificate III in Engineering - Fabrication Trade (Boilermaking/welding) qualification, you’ll need to successfully complete 96 weighting points, including 33 core and 63 speciality units. .As an apprentice fabricator (boilermaker or metal fabricator), you will learn and develop skills in metal fabrication, pattern development and, welding that are required to work as an .Become a trade-qualified sheet metal worker and collaborate with like-minded peers who love the challenge of working with metal as much as you do. Develop practical skills in fabrication as you create items like toolboxes, filing cabinets, .

tafe certificate 3

The Certificate III in Engineering - Fabrication Trade is an Apprenticeship program for apprentices employed in the metal, engineering fabrication, manufacturing or associated industries with .This qualification defines the skills and knowledge required of an engineering tradesperson - fabrication within metal, engineering, manufacturing and associated industries. The .Become a certified heavy metal working tradesperson with our Certificate III in Engineering. Master welding, metalwork & techniques for industrial projects.

2 scanner parts for cnc

This unit of competency has been developed for Engineering Tradesperson - Fabrication apprenticeship training and the recognition of trade-level skills in gas tungsten arc welding (GTAW) on heavy or light metal fabrications.Forge a career in heavy metal fabrication. Our heavy fabrication apprenticeship course will teach you to safely manipulate metal and create objects using a variety of welding techniques, thermal cutting, workshop machines, and hand and power tools.Start your career in engineering and fabrication with the nationally accredited Certificate III in Engineering - Fabrication Trade. This hands-on course is designed for apprentice boilermakers and welders in mining, manufacturing, and shipping.You’ll learn to make and repair steel and other metal products and structures such as boilers and storage tanks, and develop industry-specific skills including: arc welding; metal fabrication; forming and shaping techniques; forging and founding; structural steel erection; electroplating; metal spinning and polishing; sheet metal work

fabrication training courses

In the Certificate III in Engineering - Fabrication Trade (Boilermaking/welding) qualification, you’ll need to successfully complete 96 weighting points, including 33 core and 63 speciality units. Please note, not all specialty units are offered at every TAFE NSW location.As an apprentice fabricator (boilermaker or metal fabricator), you will learn and develop skills in metal fabrication, pattern development and, welding that are required to work as an Fabrication Tradesperson – within the metal, engineering, manufacturing or associated industries.Become a trade-qualified sheet metal worker and collaborate with like-minded peers who love the challenge of working with metal as much as you do. Develop practical skills in fabrication as you create items like toolboxes, filing cabinets, extraction systems and commercial kitchen benches.

The Certificate III in Engineering - Fabrication Trade is an Apprenticeship program for apprentices employed in the metal, engineering fabrication, manufacturing or associated industries with engineering fabrication work.This qualification defines the skills and knowledge required of an engineering tradesperson - fabrication within metal, engineering, manufacturing and associated industries. The qualification has been specifically developed to meet the needs of apprentices in the above trade.

Become a certified heavy metal working tradesperson with our Certificate III in Engineering. Master welding, metalwork & techniques for industrial projects.This unit of competency has been developed for Engineering Tradesperson - Fabrication apprenticeship training and the recognition of trade-level skills in gas tungsten arc welding (GTAW) on heavy or light metal fabrications.

Forge a career in heavy metal fabrication. Our heavy fabrication apprenticeship course will teach you to safely manipulate metal and create objects using a variety of welding techniques, thermal cutting, workshop machines, and hand and power tools.

Start your career in engineering and fabrication with the nationally accredited Certificate III in Engineering - Fabrication Trade. This hands-on course is designed for apprentice boilermakers and welders in mining, manufacturing, and shipping.

You’ll learn to make and repair steel and other metal products and structures such as boilers and storage tanks, and develop industry-specific skills including: arc welding; metal fabrication; forming and shaping techniques; forging and founding; structural steel erection; electroplating; metal spinning and polishing; sheet metal work

In the Certificate III in Engineering - Fabrication Trade (Boilermaking/welding) qualification, you’ll need to successfully complete 96 weighting points, including 33 core and 63 speciality units. Please note, not all specialty units are offered at every TAFE NSW location.As an apprentice fabricator (boilermaker or metal fabricator), you will learn and develop skills in metal fabrication, pattern development and, welding that are required to work as an Fabrication Tradesperson – within the metal, engineering, manufacturing or associated industries.Become a trade-qualified sheet metal worker and collaborate with like-minded peers who love the challenge of working with metal as much as you do. Develop practical skills in fabrication as you create items like toolboxes, filing cabinets, extraction systems and commercial kitchen benches.The Certificate III in Engineering - Fabrication Trade is an Apprenticeship program for apprentices employed in the metal, engineering fabrication, manufacturing or associated industries with engineering fabrication work.

2 inch cut out junction box

This qualification defines the skills and knowledge required of an engineering tradesperson - fabrication within metal, engineering, manufacturing and associated industries. The qualification has been specifically developed to meet the needs of apprentices in the above trade.

fabrication trade course

2 x 2 stainless steel cabinet

2 tier stainless steel pull out cabinet drawer basket

What is Fiber Laser Metal Cutting and Fabrication? A fiber laser metal cutting machine makes cutting metal a snap. With a laser metal cutter, the types of projects you can take on and the ideas you can bring to life are .

cert 3 heavy metal fabrication|fabrication trade certification fees