what are the different sheet metal processes Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious . Bolton Tools BT1440 Metal Lathes are perfect for your machine shop or your garage! The 14" x 40" BT1440 comes with a generous 1.5" spindle bore and a quick change tool post already .

0 · various sheet metal processes

1 · types of sheet metal process

2 · sheet metal working process pdf

3 · sheet metal processes pdf

4 · sheet metal process in manufacturing

5 · sheet metal operations with diagrams

6 · sheet metal forming process pdf

7 · sheet metal fabrication pdf

Search for used steel drawer cabinets. Find Lista, Clinton, Adrian Steel, Amtekco, and VWR for sale on Machinio.

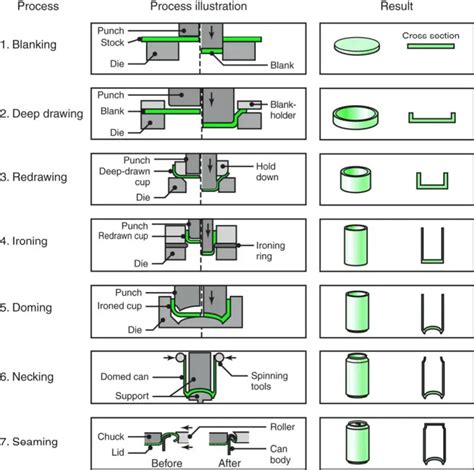

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what .The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Shearing. One of the oldest and most straightforward techniques in sheet metal working is shearing. This .Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious .

Sheet metal custom fabrication encompasses several stages of production. Design & Engineering. During the design and engineering phase, we work closely with you to gain an .

The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. This article unpacks the top ten technological processes, guiding you through each .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . Drawing is most commonly used in sheet metal fabrication processes where the final product is a box-like or cylindrical vessel. Forming. Just as the name would suggest, forming is the process of bending metal to the .

various sheet metal processes

Metal forming is broadly categorized into two major subdivisions: massive forming operations and sheet metal forming processes. What is the sheet metal forming process? Sheet metal is a thin and flat piece of metal that . Sheet Metal Cutting Operations: Sheet metal cutting operations are essential processes in metalworking, where press operation in sheet metal is subjected to various stresses to achieve precise cuts and shapes. These . For the shearing process in sheet metal, sheets are fabricated into multiple components – all of which can now be used to manufacture different items. . Versatility: You can apply the shearing process on different metal options. Just as well, the process’s ability to handle different sizes and thickness profiles speaks well of it.

Deep drawing is another widely used metal forming process. With a deep drawing, a metal sheet is clamped and placed over a cavity-shaped die. It is then punched down, which causes it to be “drawn” through the cavity — hence the name. The result is the metal sheet taking the shape of the die, which is usually cup- or box-shaped.

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. . This could range from aluminum and stainless steel to brass and copper, each offering different characteristics. Feasibility Analysis: Before .

In metal stamping processes, the types differ from one another, depending on what shape they achieve. This is done in order to create complex designs for various industries, . Instead, the die and the punch work in such a way that they both create a slit on the sheet metal. This process does not result in scrap metal pieces, such as slugs . Based upon the manufactured components and the manufacturing process, various kinds of forming are developed. Different types of sheet metal forming processes and their applications and characteristics are discussed below: Roll forming; In this process the sheet metal is passed through a large numbers of set of rollers continuously.In metal fabrication, fabricators create metal parts from raw source metals like steel, copper or aluminium.They’ll use methods like cutting, punching, bending, and welding to fabricate the parts needed for a project. Sheet metal fabrication specifically uses all of the same processes, but only flat metal sheets are used as the source to create the products.Principles of Incremental Sheet Forming Incremental Sheet Forming is a versatile manufacturing process that involves the gradual deformation of a metal sheet using a localized tool. Unlike traditional forming processes that utilize dies and molds, ISF employs a CNC-controlled tool that moves incrementally, shaping the metal sheet layer by layer.

Another common sheet metal forming process is bending. Companies typically perform bending on sheet metal using either a brake press or similar machine press. The sheet metal is placed over a die block, at which point a punch presses down onto the sheet metal. Bending doesn’t actually create holes in sheet metal. Metal forming process involves plastic deformation of a workpiece, involving a change in its shape & structure by different processes. Learn its types & advantages. . Bending is a prevalent process in sheet metal forming, where companies often utilise a brake press or a similar machine press to deform metal sheets.Study with Quizlet and memorize flashcards containing terms like What are the differences between bulk deformation processes and sheet metal processes?, Extrusion is a fundamental shaping process. Describe it, Why is the term pressworking often used for sheet metal processes? and more.Study with Quizlet and memorize flashcards containing terms like How does sheet-metal forming differ from rolling, forging, and extrusion?, Explain the difference between punching and blanking., Describe the characteristics of sheet metals that are important in sheet-forming operations. Explain why they are important. and more.

Different Types of Sheet Metals For Fabrication. There are different types of sheet metals in sheet metal fabrication. Sheet metal fabrication is essential to many industries, ranging from automotive and aerospace to . Sheet Metal Forming Processes. Let’s talk a little more about sheet metal forming’s various processes as each one is better-suited for making different items. Laser Cutting. Before metal sheets get formed, many times the .is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. In bending process, the outside portion of the sheet is in. Introduction to Metal FabricationMetal fabrication is all about shaping and assembling metal parts into final products. Think of it as playing with building blocks, but instead of plastic, we're dealing with metal. There are many ways to do this, and each method offers its own advantages depending on what you're trying to build. At its core, fabrication involves .

Deep drawing and hydroforming are two different sheet metal forming processes. Deep drawing involves using a punch to form a sheet metal blank into a three-dimensional shape by pulling it into a die cavity. It is typically used for creating cylindrical or box-like shapes with a constant depth.

In this article, we’ll examine the basics of sheet metal forming, the different processes involved, such as waterjet cutting and bending, and its importance in the fabrication and manufacturing industry. . Bottoming: In the bottoming process, the sheet metal is pressed firmly against the die, unlike air bending. This method provides greater .

Machining processes have come a long way in recent years, with fiber lasers and state-of-the-art waterjet cutters making sheet metal fabricating a fast and affordable process. However, no matter what machining process is used, parts will usually have some amount of burr, dross, or leftover imperfections immediately after manufacturing.Deformation process including metal forming and sheet metalworking. Large deformations and shape changes are defined as the bulk deformation processes. Sheet metalworking usually works with metals in the forms of sheets, strips, and coils, and these operations are performed using a punch and a die to form the object. What Does the Sheet Metal Fabrication Process Look Like? Sheet metal manufacturing involves a series of processes that transform flat sheets of metal into finished parts. Here is a general overview of how sheet metal manufacturing works: . Different sheet metal surface finishes are applied to provide various properties and aesthetics for the .

Other Sheet Metal Forming Processes Other sheet metal bending processes, like stretching and shearing, have distinct implications for fabrication. 1. Sheet Metal Stretching. This forming method expands the surface area of the worksheet without significantly altering the thickness. Stretching is best to create large-radius curves and complex shapes.Study with Quizlet and memorize flashcards containing terms like Describe (a) the similarities and (b) the differences between the bulk deformation processes considered last week, and the sheet-metal forming processes looked at in this week's lecture., Q2. A sheet metal component is required to have a high quality edge, (both smooth and close to perpendicular to the surface of .

It’s the operation of cutting, shaping, punching, and pressing sheet metal to assemble it into finished products. Sheet metal fabrication often starts with metal shearing, which prepares the material for subsequent operations such as bending or welding. It’s a process that cuts sheet metal into specific shapes and sizes.As you can see, there are numerous sheet metal processes and they can all be used in a variety of different ways. The sheet metal process chosen will largely depend on the goals of the manufacturer and how the material is going to be utilised.

machine tech cnc

machining cnc titanium auto parts factory

I'd suggest buying a small junction box and installing it so the incoming cable has enough length, splice on new wire, then run the new wire the rest if the way to the current box.

what are the different sheet metal processes|sheet metal operations with diagrams