what are the benefits of cnc machining What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process . eMachineShop offers cost-effective cutting solutions whether you need a single part, batch of prototypes, or a production order. 50+ Materials. FREE Shipping in the USA.

0 · pros and cons of machining

1 · disadvantages of cnc milling

2 · disadvantages of cnc

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · cnc advantages and disadvantages

Products Archive - CNC Replacement Parts. This carousel replaces the 10-pocket tool plate for BT or CT machines. It is compatible with part number 93-0403. Order the Umbrella Easy Tool with a carousel plate to receive a discount on the Easy Tool.

This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, .

CNC machining is an economical, efficient, and precise process of manufacturing parts and products. CNC machining also uses fewer raw materials in comparison to conventional machining. Focusing your shop around CNC . What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process . CNC machining produces everything from vehicle armor to weapon systems with the precision and consistency necessary for high-stakes applications. CNC machines can .One of the most significant benefits of CNC machining is its ability to produce parts with unparalleled precision and accuracy. By using computer-controlled machines, it ensures that every component is crafted to exact specifications, .

While CNC machining offers a plethora of benefits, there are a few disadvantages to consider as well. Human programming errors can occur, leading to mistakes in the production process. Thus, proper training in programming . The Major Benefits of CNC Machining. While the specific applications of CNC machine vary greatly from one machine to the next, all these sophisticated CNC machines have become widely used in a variety of .

pros and cons of machining

CNC machining, or Computer Numerical Control machining, has revolutionized the manufacturing industry by allowing for the automation of precision machining tasks.This technology uses programmed computer software to control the movement of tools and machinery, enabling manufacturers to create intricate and high-quality parts from materials like metals, plastics, . Some of the benefits of CNC machining include a fully computerized production process, which is faster and more precise and requires minimal human intervention. But that’s not the only advantage CNC machining offers. Learn the ins and outs of CNC machining and how it improves the manufacturing process. The CNC machine removes parts of the workpiece by machining operations such as turning, drilling, or milling, according to codes (g-code and m-code) obtained from the CAD model and containing instructions on machining parameters.

CNC machining enhances manufacturing efficiency, precision, and cost-effectiveness across industries like automotive, aerospace, medical, electronics, and construction. Its key benefits include high accuracy, repeatability, flexibility, reduced labor costs, and material versatility, making it essential for producing complex, high-quality components. In today’s competitive manufacturing landscape, precision and efficiency are paramount. Companies seeking to optimize their production processes often turn to CNC machining services. While some choose to keep these operations in-house, an increasing number of businesses are realizing the advantages of outsourcing CNC machining. Another benefit, CNC machining allows for the creation of consistent parts. This eliminates variances which are common with manual production. Unlike human labor, CNC machines can work continuously This allows manufacturers to meet demanding deadlines. Once programmed, CNC machines only need to stop for occasional service.CNC Machining has proved to be another tool 3D printing customers can take advantage of for optimized parts. As a secondary process, CNC machining provides additional dimensional accuracy on additive parts while maintaining all the benefits of 3D printing technologies like FDM (Fused Deposition Modeling).

High-speed CNC machining has many benefits over traditional machining methods. The higher speed and feed rate employed in HSM result in rapid cutting, minimal heat transfer and decreased shop emissions, along with numerous other advantages. These are the main benefits of rapid CNC machining: 1. Extends Equipment Life Span

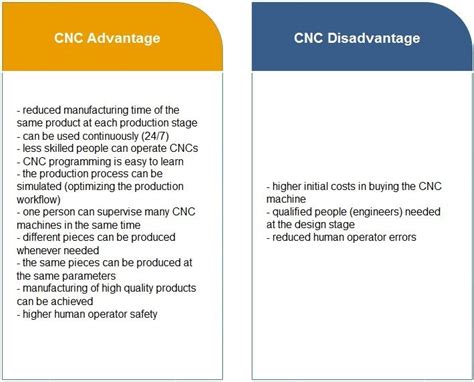

Apart from a number of other benefits, the main benefits of the CNC machines are: superior automation, accuracy and flexibility. The process of the CNC machines is fully automated. The need of the operators can be reduced to minimum or it can be totally eliminated. The CNC machines offer highly accurate jobs which may be very difficult and time consuming for the .CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision.Using this type of machine versus manual machining can result in improved accuracy, increased production speeds, enhanced safety, increased efficiency, and most of all cost savings. What are the Benefits of CNC Machining? The accuracy of the CNC machine ensures consistent product quality. The process is more precise than manual machining and . Benefits of Completing CNC Machine Training. A career as a CNC machinist can be exciting, and skilled machinists are in demand, which can open the door to a variety of opportunities. Some benefits of CNC machining training include: Gain the skills and knowledge needed to pursue a career as a CNC technician.

CNC milling is a specific type of CNC machining that leverages computerized controls and a milling machine to progressively remove material from a solid block in order to produce a part. A milling machine is similar to .What is CNC Machining? CNC machining is a manufacturing process that uses computer-controlled machines to create precise parts. It stands for "Computer Numerical Control." How CNC Machining Works . CNC machines operate using pre-programmed software and code. This code controls the movement of cutting tools, such as drills and lathes. The .

Benefits Of CNC Machining. CNC machining is outstanding for several reasons: 1. They’re More Accurate, Producing Minimal Defect. Ditch the manual woodwork since you’ll still see measurement inaccuracies even if you have accumulated years into this. Instead, choose CNC machines that can receive accurate computer instructions to provide . Manufacturers of all types in virtually every industry—from agriculture to medical and everything in between—choose the benefits of CNC machining over traditional manufacturing methods. CNC machines deliver a production capacity ideal for creating large quantities of items which require accurate, consistent, complex cuts. Conclusion – Benefits of CNC Machining. CNC machining has been a staple of the industry for many years due to its accuracy and efficiency. It is able to create complex designs with precision control, allowing manufacturers to produce intricate parts . Benefits of CNC Machining. Advancements in modern technology have revolutionized manufacturing processes. As a result, CNC machines provide various advantages during manufacturing. The benefits include: Increased Production Speed: Modern CNC machines excel in efficiency. They can seamlessly switch cutting tools, eliminating the need for manual .

Types of CNC Machines. The most common types of CNC machines are those that use cutting tools to remove excess material from the workpiece. While there are CNC machines that employ water jet cutting and electrical discharge machining (EDM) operations, this guide will focus on the five most common categories in the following list, divided into two basic .

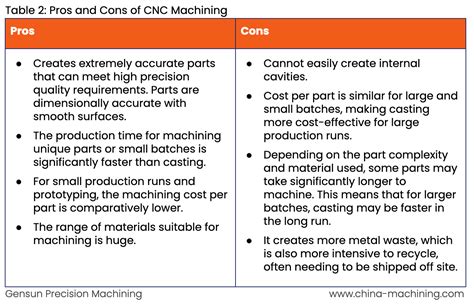

The benefits of CNC milling are pushing the manufacturing industry, ensuring unparalleled precision and efficiency in production processes. A recent survey highlighted that enterprises adopting CNC milling witnessed a staggering 30% increase in production speed. Furthermore, the accuracy of CNC technology has led to a notable 40% reduction in material . The benefits of CNC machining, such as speed, precision, and efficiency, cannot be matched by any other technology. Even when you weigh the pros and cons of CNC machining, the advantages, like the ability to produce complex geometries with high repeatability and the reduction in labor and material costs, always win out in the end.

Another benefit of CNC machine control units is the increased speed of production. By programming the exact movements of the cutting tool, the machine can move faster than a human operator, resulting in a faster production rate. This can be especially beneficial in high-volume production runs. CNC machining has gained popularity in the automotive sector in recent years due to its numerous benefits. The following are some benefits of CNC machining in the automotive industry. High Repeatability. CNC Machining in the automotive industry guarantees repeatability because it is a computer-controlled process.

Top Applications of CNC Machining in Different Industries. CNC machining is crucial throughout many different industries. The core benefits we explored are valuable in everything from oil and gas to aerospace. Any component that needs to be precisely manufactured to create durable results can likely benefit from CNC machining.

Copper’s unique benefits and properties make it a valuable material for a wide variety of applications. Copper has excellent electrical conductivity, high corrosion resistance, and is easy to machine. With copper CNC machining, precise copper parts can be produced quickly and with a high level of repeatability, ensuring each part meets strict requirements and specifications.

disadvantages of cnc milling

Buy grease, bearings, RS232 cables, surface plates, maintenance tools, CNC software, oil, training software and industrial supplies. Authorized distributor for thousands of electrical parts. Call Us (414)881-4493

what are the benefits of cnc machining|pros and cons of machining