cnc machine capacity planning Manufacturing capacity planning is a part of overall production planning that seeks to quantify how much productive capability a company has and how much it needs to complete its order position. This includes labor and workforce capacity requirements, product mix, supply chain, and other variables. Verizon Wireless Services; 18 people had this problem. I have the same question. 0 Likes Reply. 1 Solution An Accepted Solution is available for this post. . Verizon Wireless. PO Box 660108. Dallas, TX 75266-0108. Helped me too. 1 Like Reply. An Accepted Solution is available for this post. Jump to solution. Mark as New; Bookmark; Subscribe;

0 · machine capacity calculation formula

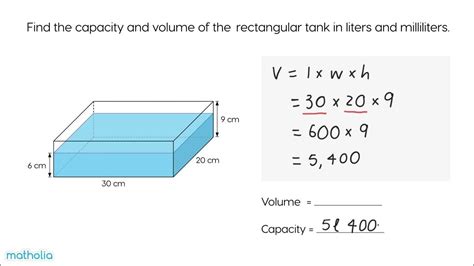

1 · how to figure out capacity

2 · how to calculate the capacity

3 · how to calculate monthly capacity

4 · how to calculate machine capacity

5 · how to calculate capacity utilization

6 · how to calculate capacity planning

7 · free excel capacity planning tools

$38.98

machine capacity calculation formula

Manufacturing capacity planning is a part of overall production planning that seeks to quantify how much productive capability a company has and how much it needs to complete its order position. This includes labor and workforce capacity requirements, product mix, supply .Capacity analysis helps manufacturers understand their production capabilities .

gas electric meter box latch

Manufacturing capacity planning is a part of overall production planning that seeks to quantify how much productive capability a company has and how much it needs to complete its order position. This includes labor and workforce capacity requirements, product mix, supply chain, and other variables. Manufacturing capacity planning is the process used to establish how much of your resources are required to fulfill demand. Capacity planning is made up of three resource types: machines, people, and tools. One or more of these types are used to . Capacity analysis helps manufacturers understand their production capabilities and identify potential bottlenecks. Accurate capacity planning ensures that resources are utilized efficiently and production targets are met. By analyzing capacity, manufacturers can make informed decisions about scaling operations or optimizing existing processes.

Here is how I handle this situation: Base your process capacity on the best machine, and then add to that capacity these "backup" machines adjusted for efficiency.Optimizing CNC machine capacity is crucial for manufacturers aiming to enhance their productivity and stay competitive in the modern manufacturing landscape. By understanding the factors that affect machine capacity, implementing effective strategies, and prioritizing regular maintenance, businesses can unlock the full potential of their CNC .

There are several different ways for determining your production capacity: manually measuring the capacity, Rough-Cut Capacity Planning (RCCP), and Capacity Planning and Scheduling.In this comprehensive guide, we will delve into the factors that influence CNC machine rates, how they are calculated, and explore strategies to optimize machine rates for improved profitability and productivity. 1. Understanding CNC Machine Rates:\When you think of a CNC machine shop, you may first think of production floor KPIs: how efficiently machines are running, actual throughput versus projected, or percentage of pieces that are defects. Those are all worthy KPIs, yet there should be more measuring going on, both in leading and lagging indicators.

An ERP system can support solid capacity planning processes individually, or as a combination of many modes of manufacturing (make-to-stock, make-to-order, etc.). Scheduling functionality allows for instant and real-time analysis of current capacity loads, and how an incoming order may affect your capacity.JITbase helps to improve workforce efficiency and increase production capacity by collecting data from machines that no one else can access. Manufacturing capacity planning is a part of overall production planning that seeks to quantify how much productive capability a company has and how much it needs to complete its order position. This includes labor and workforce capacity requirements, product mix, supply chain, and other variables. Manufacturing capacity planning is the process used to establish how much of your resources are required to fulfill demand. Capacity planning is made up of three resource types: machines, people, and tools. One or more of these types are used to .

Capacity analysis helps manufacturers understand their production capabilities and identify potential bottlenecks. Accurate capacity planning ensures that resources are utilized efficiently and production targets are met. By analyzing capacity, manufacturers can make informed decisions about scaling operations or optimizing existing processes. Here is how I handle this situation: Base your process capacity on the best machine, and then add to that capacity these "backup" machines adjusted for efficiency.Optimizing CNC machine capacity is crucial for manufacturers aiming to enhance their productivity and stay competitive in the modern manufacturing landscape. By understanding the factors that affect machine capacity, implementing effective strategies, and prioritizing regular maintenance, businesses can unlock the full potential of their CNC . There are several different ways for determining your production capacity: manually measuring the capacity, Rough-Cut Capacity Planning (RCCP), and Capacity Planning and Scheduling.

In this comprehensive guide, we will delve into the factors that influence CNC machine rates, how they are calculated, and explore strategies to optimize machine rates for improved profitability and productivity. 1. Understanding CNC Machine Rates:\When you think of a CNC machine shop, you may first think of production floor KPIs: how efficiently machines are running, actual throughput versus projected, or percentage of pieces that are defects. Those are all worthy KPIs, yet there should be more measuring going on, both in leading and lagging indicators. An ERP system can support solid capacity planning processes individually, or as a combination of many modes of manufacturing (make-to-stock, make-to-order, etc.). Scheduling functionality allows for instant and real-time analysis of current capacity loads, and how an incoming order may affect your capacity.

how to figure out capacity

how to calculate the capacity

gauge sheet metal thickness

how to calculate monthly capacity

Sleek and versatile, the Corten Steel Window Box Planter is the perfect addition to any window, deck or patio. Featuring a rusted patina finish and a modern trough design, the Window Box planter looks sharp lined along a walkway, or placed underneath a window.

cnc machine capacity planning|how to figure out capacity