cnc machining for the dental industry WORKNC DENTAL – Automatic 3 to 5-axis machining for the Dental industry. WORKNC DENTAL provides an easy to use, step by step interface that allows for milling of complex . This page contains wiring diagrams for most household receptacle outlets you will encounter including: grounded and ungrounded duplex outlets, ground fault circuit interrupters (GFCI), 20amp, 30amp, and 50amp receptacles for 120 volt and 240 volt circuits.

0 · milling machine for dental lab

1 · digital dental milling machines

2 · dental milling machines for sale

3 · dental milling machine for crowns

4 · dental crown milling machine price

5 · best dental milling machines

6 · best dental cad cam system

7 · 5 axis dental milling machine

Eastman then demonstrates how to install a new junction box in the basement: Choose a suitable location on the basement wall. Place the outlet against the wall and mark the screw locations. Use the hammer drill and masonry bits to drill into the block wall, and use masonry screws to fasten it.

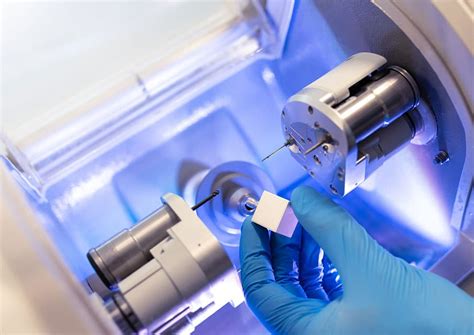

The CNC machine technology allows dental labs to produce high-quality teeth prosthetics faster and more economically than conventional methods. Additionally, CNC technology provides . CNC machining represents the pinnacle of automated technology in dentistry. It involves using computer-controlled tools to create precise and intricate dental restorations. .

As a backup to the CHARLYDENTAL CDO4-S CNC machine, this model has 5 axes positioned to machine soft and ceramic dental prostheses, dry or with lubricated tools. Its high power .WORKNC DENTAL enables automatic and interactive 3+2 re-machining using the cavity detection or direct selection of the re-machining areas. Undercuts can be milled very quickly in .WORKNC DENTAL – Automatic 3 to 5-axis machining for the Dental industry. WORKNC DENTAL provides an easy to use, step by step interface that allows for milling of complex .

A CNC machine is a type of automated milling or cutting machine that can be programmed using computer software to manufacture different types of dental prosthetics, such as crowns, .CNC machining is commonly used to produce orthopedic implants like hip and knee replacements, spinal implants, and dental prosthetics. These components need to fit precisely within the patient’s body to ensure comfort, stability, and .

In the modern dental industry, digital dentistry is the future. vhf offers optimal CAD/CAM milling machines for every laboratory and dental office. Whether dry or wet processing – we have the perfect solution for you, which will put you in the .

Find your dental cnc milling machine easily amongst the 9 products from the leading brands (MECANUMERIC, isel, Conprofe, .) on DirectIndustry, the industry specialist for your professional purchases.Toolpath generation is totally automatic and users do not need any CAM or CNC milling experience to machine dental components. WORKNC DENTAL includes more than 70 High End 3 to 5-axis toolpaths. . The optimized sequences . CNC Machining in the Dental Industry In the dental field, CNC machining plays a crucial role in fabricating precise and customized dental restorations. From crowns and bridges to implants and orthodontic appliances, CNC machines can produce high-quality dental products with minimal human intervention. This technology ensures that each piece is .

For example, 5-axis CNC machining is widely used in dental medicine to produce titanium alloy implants for dental implants, ceramic crowns, and other parts. . Medical CNC machining is a highly regulated industry due .

With its five fully interpolating CNC axes and a pick-and-place automatic tool loader, the machine can be readily adapted for many types of dental cutting instruments for both short and long runs. Compared to five-axis machines, the model CNC246F is an example of a dedicated, productive three-axis fluting machine suitable for flute and relief .The Roles of CNC Machining in the Medical Industry. The healthcare sector relies on CNC machining to produce medical prototypes and components that require tight tolerance and performance standards demanded by the industry. There are several reasons why CNC machining is extensively used in the medical field: 1. No limitations on quantitiesHigh-speed CNC machining of dental instruments He also speaks highly of the significantly faster kinematics in the X, Y, Z and A axis (rotational axis), . Sirona is the technology and market leader in the dental industry and a worldwide partner for dental practices, clinics, dental laboratories and authorised distributors. .WORKNC DENTAL – Automatic 3 to 5-axis machining for the Dental industry. WORKNC DENTAL provides an easy to use, step by step interface that allows for milling of complex dental prosthesis without CAM milling experience. . WORKNC DENTAL Optimized CNC Milling. Optimized CNC machining templates for each type of material and its application .

Such instruments machining typically requires high-quality CNC machining machines, CNC lathes, and other specialized equipment. This is why several sectors in the medical industry rely on us for their machining needs, as we own both the expertise and experience in meeting requirements, no matter how challenging they are.

Over 86% of Fortune 500 medical products and equipment companies depend on our production capabilities such as an industrial-grade 3D printing service, high-tech CNC machining processes, and advanced medical injection molding for rapid prototyping, product testing, custom tooling, and custom design manufacturing.For over 17 years we have produced screw machine products for the dental industry while maintaining quality and adhering to the exacting standards of the dental health industry. . With a highly experienced staff to our technologically advanced machines, our CNC Swiss dental machining is industry leading. Alpha Omega Swiss is a known expert in . First, let us address the applications of CNC machining in the healthcare industry. Surgical Instruments. . Zirconia – Known for its excessive energy and fracture resistance, utilized in dental implants and crowns. Alumina – Offers tremendous hardness and wear resistance, making it best for joint replacements and different put-on-vital .

In 2001 the business added CNC Swiss turning centers to run production plastic tooling parts for the dental industry. Today the business has the ability to run CNC Swiss turning centers with the maximum capacity of .750 diameter, turning materials from plastics, stainless steels, titanium and other precious metals such as silver.

It's no secret that additive manufacturing affects many sectors and industries. In particular, it offers significant advantages in terms of productivity, cost, customization and manufacturing time.One of the most important applications of 3D printing is dentistry. In this branch of medicine, technology makes it possible to provide personalized dental solutions.

With CNC machining, the medical industry can ensure high-quality patient care and better outcomes for patients. Table of Contents. . Dental & Orthopedic Devices: CNC machining has had a major impact on the production of dental and orthopedic devices, as these devices require high precision in their manufacture. .Find out all of the information about the Kern Microtechnik GmbH product: 5-axis CNC machining center KERN Micro Pro. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of . what is the applications of cnc machining for medical and dental industry? 8618018752893. [email protected]. Language. English; русский ; Deutsch; suomi; íslenska;

A simple guide to selecting a CAD/CAM milling machine. CAD/CAM milling machines have only developed over the past few years, but today’s dental laboratories now feature various milling options. Even while the inner .The significance of CNC machining extends to the field of dentistry, where it plays a crucial role in providing exceptional dental care through the creation of tailor-made dental tools and implants. Dentists across the globe depend on advanced CNC . Benefits of CNC Machining Medical industry products and parts require the manufacturing process chosen must have the ability to meet tight tolerance limits necessary for proper function. Dimensions of features to be created are often at a micron length scale. . The company specializes in CNC machining, 3D printing, urethane casting, rapid .

The CNC Machining Skills Gap: A Q&A with Tony Schmitz on Training Tomorrow’s Workforce . Technology. Automotive Industry Trends: 3 Things to Watch for in Electric Car Manufacturing . “The dental industry uses cobalt chrome and titanium, ceramics such as zirconia and alumina, and high-strength polymers like PEEK and PMMA,” Dyer says . Advances and benefits of CNC machining in the medical industry A great advantage of CNC machining is the high precision it offers. In the medical sector, precision and accuracy are essential factors, especially in implantable devices or surgical instruments, where the slightest deviation or anomaly can mean the difference between success and . CNC machining is important to handle the increasing demand for high-quality precision machined parts and prototyping in the medical industry. These CNC machined medical equipment and instruments must be on-demand manufacturing and meet the industry’s standards. Therefore, product teams and manufacturers rely on CNC machining to meet quality standards .

milling machine for dental lab

These advanced machines have revolutionized the dental industry by improving accuracy, precision, and efficiency in the production of dental implants. This article will explore the vital role of CNC machines in dental implant manufacturing and highlight their numerous benefits. 1. Advanced Technology for Precise Implant Design\

Precision Guaranteed: Machining to the Highest Medical Industry Standards When it comes to medical machining, Owens Industries is the answer. Excelling in the craft of 5-axis milling and electrical discharge machining, our engineers are a favorite among manufacturers of cardiovascular and orthopedic devices, surgical instrumentation and implants.. Miniature parts .Find out all of the information about the Kern Microtechnik GmbH product: 5-axis CNC machining center KERN Micro Vario. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale. Discover 8 key applications of CNC-machined parts in the medical & healthcare industry. From surgical instruments to dental tooling, see how CNC machining revolutionizes medical manufacturing. Contact us at Rapid Axis for a free quote.

Industry Application CNC POR Use; Prosthetic Manufacturing: The production of custom prosthetics relies on CNC POR’s ability to create highly individualized and intricate components. Dental Implantology: Precision is paramount in dental implants. CNC POR ensures accurate manufacturing for the dental industry. Medical Device Production

sheet metal hole punch press

sheet metal hole punch set

What is a Junction Box: Discover the essential functions of junction boxes in electrical wiring systems. Learn about different types, their key.

cnc machining for the dental industry|digital dental milling machines