how to curve sheet metal Professional metalworker with 45+ years experience Jim Jim shows you how to properly work sheet metal into a nice curve. Surface-mount raceways are available: they consist of boxes that mount over existing outlets, where the wire to be put in the raceway is wired into existing electrical work, then running the raceways to a new location, and mounting a surface box for another outlet/light/etc.

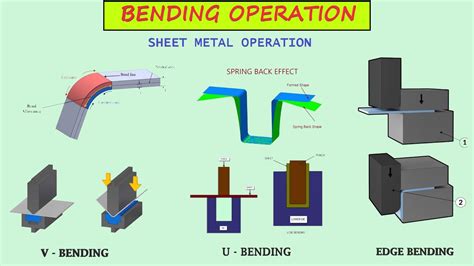

0 · types of sheet metal bending

1 · sheet metal curved flange

2 · flanging tool for sheet metal

3 · cutting and bending sheet metal

4 · bending sheet metal by hand

5 · bending sheet metal at home

6 · bending sheet metal 90 degrees

7 · bending 18 gauge sheet metal

Used Sheet Metal Box and Pan Brakes from National, Diacro, and more. Find suppliers near you at the world's leading directory for surplus machinery.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more Professional metalworker with 45+ years experience Jim Jim shows you how to properly work sheet metal into a nice curve. Forming radius bends in sheet steel would normally be done with slip rolls - but acceptable work for a lot of jobs can be done using a piece of pipe. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or angular shape. This process is commonly used in forming various components such as .3.99

.998.99Folding involves bending the metal back onto itself, while roll bending creates curved sections or full cylinders by passing the sheet metal through rolls. These techniques allow for more intricate designs and shapes.

Hi, I have a model of a nameplate which is flat. However, I need to attach it to a curved surface. I would like to modify the model so that I keep the flat part as the generic model and the curved as the model used in the . On this episode of Make It Kustom, I BUILD a shrinker tool from scrap metal Follow along to learn how to make your own sheet metal shrinking tool.Join this c. Clamp the box section on top of the shims, feed the metal through and pull up, then feed the metal through a few mm at a time, gentle tweaks, using the long side, when you reach the middle turn it round and repeat. I have bent 3mm sheet up to 300mm wide like this. Note watch out for overbending the workpiece. For 3mm I use a big piece of angle iron

Every tutorial brings new abilities.You can slow the film on Youtube by using the Settings (bottom right), selecting Normal, and choosing a subunitary Playba. How to create a corrugated sheet metal curve Hi all, I'm trying to create a tank with corrugated sheets, I can make the corrugated sheet but I can't bend it. Here is an example photo and my attempt. Please help me. Solved! Go to Solution. Solved by johnsonshiue. .

Most frequently, expensive sheet metal bending tools, called brakes, are used to bend sheet metal, but you can also complete this task without one. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

Sheet metal curve I have modelled up an armour section for a combat robot and want to get it waterjet cut so need the flat profile of it, so I would like to try making the same part using the sheet metal tools. However I cannot figure out how to change the angle of the next flange? Tags (2) Tags: curve. sheet metal. Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or angular shape. This process is commonly used in forming various components such as brackets, flanges, or panels in automotive fabrication. If you’ve ever made a paper airplane, you’re already familiar with how this works. . Metal shaping tips: old school hand forming a curved panel with a flange, using my Eastwood beater bag and poly hammer, shrinking stump, shaping hammer, , pl.

types of sheet metal bending

Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.

You can create your sketch like as picture and use "Contour Roll Comand" first u should choose profile and 2nd you should choose axis then you can create.Sheet Metal SOLIDWORKS 2016 Tutorial for Beginners ~ How to Create a Curved Sheet Metal Part and then Cut Lettering Out of It. Arco shows how to quickly shape a panel, 20 ga sheet metal for the front of the SEMA carAmazon store: www.amazon.com/shop/outlawedgePatreon: https://www.patr.

How To Make Inside Cuts On Sheet Metal By Hand:The "How To Make A Metal Project Enclosure" video answered how to make outside cuts on thin sheet metal and th.

#KevinCaronArt #MetalworkingTips #ArtistKevinCaronFrom http://www.kevincaron.com - Artist Kevin Caron shows a tip for bending thick metal with tools almost e.Hi u/ThatsJeem, . This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command (GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend).I will caution you though that using . If you feel that you would like to help support Trev’s Blog channel please consider making a donation, money raised from donations will be used to buy tools .So I managed to get it to bend by adding a very small horizontal line to the curve of the gutter so that it could select a 'fixed face'. But for some reason, after the fold action the two sides of the shape get cut off and I can't figure out why.

On this episode of Make It Kustom, I install a 1980s Jaguar gas cap in a 1948 Plymouth fender using simple tools to stretch the flange of the Plymouth sheet . Once you’re satisfied with the shape and smoothness of your curved sheet metal, the final step is to finish your piece. Using fine-grit sandpaper, polish the entire surface of the sheet metal to remove any sharp edges and give it a smooth, professional appearance. After sanding, wipe down the metal with a clean cloth to remove any dust or .

I have a rectangular piece of sheet metal and all I want to do is make the sheet curved with a radius of 113.75 in. How do I go about this? Is there an easier way like making a 3d sketch and putting a sheet metal face on it? I'm a beginner and any help is greatly appreciated!

In today's video we will discuss how to Tip a Flange on a Radius. Tipping a Flange on a Curve is an excellent way to recreate original components such as fe. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

sheet metal curved flange

Bends in the sheet metal module must be sections of a cylinder. Not true, you can achieve more complex bends using the lofted bend tool. However, you cannot create a compound bended surface, i.e. one that curves in 2 directions at once.

Hello, So in real life the process is going from a piece of flat sheet metal, putting it into a break and making a piece of angle, then putting it through a roll bender to get a circular piece of angle for making a flange. I've searched the forum and couldn't really find anything that was relevant to this. Ive tried experimenting a couple ways, and I'm starting to guess that .In this video, I am going to explain about how to create Surface to Sheet Metal component by using Forming Tool.-----. Sheet metal bending in architectural design is a captivating process that transforms buildings with curved metal, unleashing creativity and pushing the boundaries of architectural aesthetics. By combining technical expertise, artistic vision, and the right materials, architects can breathe life into their designs, creating structures that .

I have a 4" round backplate sconce I need to install. The receptacle is a standard rectangular single gang box. I'm having a tough time finding an adapter plate, ideally black, which will A.) Cover the duplex and B.) Attach the sconce to.

how to curve sheet metal|bending sheet metal at home