do we need junction box for 90deg turn Anywhere you have wires spliced together, you need a junction box. Building codes require this protection because contact between wires can cause a spark. That's dangerous. Metal roofs do not make houses hotter; in fact, they can keep homes cooler due to their reflective properties. Insulation and ventilation play crucial roles** in regulating the temperature of your home, regardless of the roofing material.

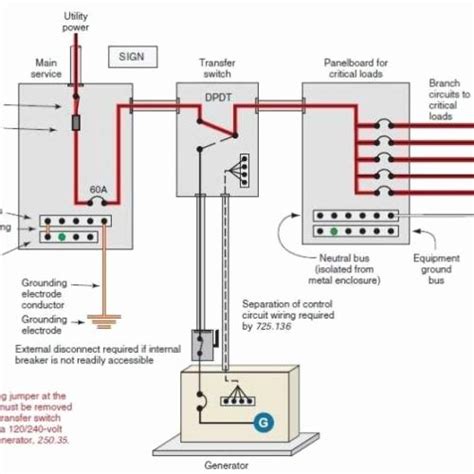

0 · wiring questions for inlet box to transfer switch

1 · electrical

2 · Sizing Junction Boxes

3 · Pull Box Required

4 · New Generator Circuit

5 · NEC Requirements for Sizing Junction Boxes and Pull Boxes

6 · Homeowners Ask: Are Junction Boxes Necessary?

7 · GFCI and ground for a gas stove? : r/HomeImprovement

8 · DIY Wiring: How to Safely Install and Use Junction Boxes

9 · A Full Guide on the NEC Electrical Codes for Junction Boxes

Yes, fabric paint can work on metal. It is best to use a primer before painting so that the paint will adhere better and last longer. You can also use spray paint for a more even coverage.

Estimated 30 ft linear cable distance from inlet box entry location to transfer switch. My primary questions are on the recommended type of cabling, how I handle turns, and how I attach the cabling to the cinder block walls. Vertical pulls present a completely different set of rules. Conductors are required to be supported. If you have a 500' straight vertical pipe run and pull in 500 Kcmil conductors .

Is it allowed for a wire to go directly into a wall from PVC conduit (with some connector)? Or do I need to install a junction box? I've found plenty of raintight couplings and box connectors, so I'm good there. But I do need to make four tight 90 degree turns and I can't seem to find any elbow or conduit body .

Anywhere you have wires spliced together, you need a junction box. Building codes require this protection because contact between wires can cause a spark. That's dangerous. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, .

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely . The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in .

I see no evidence 240V wiring (but I haven't looked in the wall or junction box). The adapters only serve to 1) turn the plug 90deg and 2) change from 3-prong to 2-prong. My .

What Are the NEC Requirements for Junction Boxes and Enclosures? The NEC has outlined specific requirements for junction boxes to ensure the safety and proper installation of . Estimated 30 ft linear cable distance from inlet box entry location to transfer switch. My primary questions are on the recommended type of cabling, how I handle turns, and how I attach the cabling to the cinder block walls. Vertical pulls present a completely different set of rules. Conductors are required to be supported. If you have a 500' straight vertical pipe run and pull in 500 Kcmil conductors you'll need a pull box every 50' to support the conductors. There is no junction box behind. The wires come out from a hole in the siding and are connected with wire nuts and tucked behind the light. Do I need to add some sort of junction box?

Is it allowed for a wire to go directly into a wall from PVC conduit (with some connector)? Or do I need to install a junction box?

sheet metal processing company

wiring questions for inlet box to transfer switch

I've found plenty of raintight couplings and box connectors, so I'm good there. But I do need to make four tight 90 degree turns and I can't seem to find any elbow or conduit body that is specifically listed as raintight. Anywhere you have wires spliced together, you need a junction box. Building codes require this protection because contact between wires can cause a spark. That's dangerous.

Yes, the total degrees of all bends between junction boxes or conduit bodies can not exceed 360 degrees. This should be in each applicable wiring method article such as xxx.26. For example EMT is 358.26. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).

Estimated 30 ft linear cable distance from inlet box entry location to transfer switch. My primary questions are on the recommended type of cabling, how I handle turns, and how I attach the cabling to the cinder block walls. Vertical pulls present a completely different set of rules. Conductors are required to be supported. If you have a 500' straight vertical pipe run and pull in 500 Kcmil conductors you'll need a pull box every 50' to support the conductors. There is no junction box behind. The wires come out from a hole in the siding and are connected with wire nuts and tucked behind the light. Do I need to add some sort of junction box?

Is it allowed for a wire to go directly into a wall from PVC conduit (with some connector)? Or do I need to install a junction box? I've found plenty of raintight couplings and box connectors, so I'm good there. But I do need to make four tight 90 degree turns and I can't seem to find any elbow or conduit body that is specifically listed as raintight.

Anywhere you have wires spliced together, you need a junction box. Building codes require this protection because contact between wires can cause a spark. That's dangerous.

Yes, the total degrees of all bends between junction boxes or conduit bodies can not exceed 360 degrees. This should be in each applicable wiring method article such as xxx.26. For example EMT is 358.26. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

electrical

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

sheet metal practice test

$5.40

do we need junction box for 90deg turn|wiring questions for inlet box to transfer switch