cnc drawing machine parts CNC machines can fabricate complex parts with high accuracy and consistency using detailed orthographic views. Section views facilitate a better understanding of the internal workings of a part critical to ensuring its . HOME MASTER HARDWARE 12 inch x 8 inch Heavy Duty Shelf Brackets, Load Capacity: 600lb, Black Metal 90 Degree Supports for Shelves 10-Pack, Wall Mounted L Bracket for Floating Shelving with Screws

0 · vertical milling machine drawing

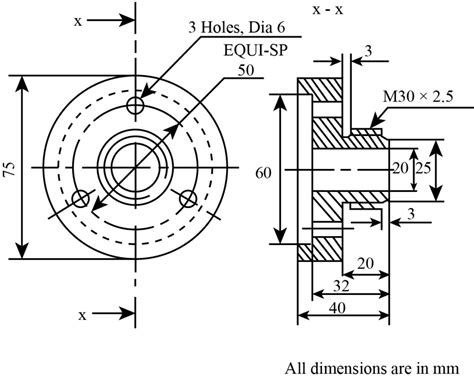

1 · machine parts drawing with dimensions

2 · create cnc file from drawing

3 · cnc turning machine drawing

4 · cnc pen plotter circuit diagram

5 · cnc machine drawing pdf

6 · 3d printable cnc machine

7 · 2d drawing and cnc turning

This Hyper Tough 16-Inch Black Metal Toolbox with Removable Tray (model 3482V) allows for convenient storage and portability of your tools. The tool box has many high quality features like a lockable metal latch and removable metal tray.

CNC machines can fabricate complex parts with high accuracy and consistency using detailed orthographic views. Section views facilitate a better understanding of the internal workings of a part critical to ensuring its . CNC machining drawings are the jewels upon which CNC machines depend so much for bringing designs into real life. These part drawings and machining blueprints that are included as sets provide all the details with .In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few .Providing a technical drawing can help you source better parts and even reduce your costs. In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get .

There are several components that are part of technical drawings. Among the most important components are the title block, the isometric view, the orthographic view, the coordinates, the section view, and the detail view. Technical drawing involves the use of various tools and techniques to accurately and precisely create diagrams, blueprints, and other visual representations of mechanical or architectural designs. Here, I will take . Learn more about the different parts of a CNC machine and their functions. CNC (computer numerical control) machines are complex pieces of equipment designed to automatically manufacture parts from a wide range of . CNC machines rely on these technical drawings to produce highly accurate and precise parts. A technical drawing is a detailed illustration that shows every aspect of the part, including its size, shape, and dimensions.

CNC machines can fabricate complex parts with high accuracy and consistency using detailed orthographic views. Section views facilitate a better understanding of the internal workings of a part critical to ensuring its accurate and efficient machining. CNC machining drawings are the jewels upon which CNC machines depend so much for bringing designs into real life. These part drawings and machining blueprints that are included as sets provide all the details with every dimension, tolerance, and specification needed for the production of parts with the highest level of accuracy.

vertical milling machine drawing

A technical drawing for CNC Machining is an essential part to build a 3d part by CNC machining. It provides a detailed representation of the part or product that needs to be machined, allowing manufacturers to accurately produce the desired outcome.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders.Providing a technical drawing can help you source better parts and even reduce your costs. In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing.

There are several components that are part of technical drawings. Among the most important components are the title block, the isometric view, the orthographic view, the coordinates, the section view, and the detail view. Technical drawing involves the use of various tools and techniques to accurately and precisely create diagrams, blueprints, and other visual representations of mechanical or architectural designs. Here, I will take a brief look at some key components of technical drawings for CNC machining.

Learn more about the different parts of a CNC machine and their functions. CNC (computer numerical control) machines are complex pieces of equipment designed to automatically manufacture parts from a wide range of materials that . CNC machines rely on these technical drawings to produce highly accurate and precise parts. A technical drawing is a detailed illustration that shows every aspect of the part, including its size, shape, and dimensions. CNC machines can fabricate complex parts with high accuracy and consistency using detailed orthographic views. Section views facilitate a better understanding of the internal workings of a part critical to ensuring its accurate and efficient machining.

CNC machining drawings are the jewels upon which CNC machines depend so much for bringing designs into real life. These part drawings and machining blueprints that are included as sets provide all the details with every dimension, tolerance, and specification needed for the production of parts with the highest level of accuracy. A technical drawing for CNC Machining is an essential part to build a 3d part by CNC machining. It provides a detailed representation of the part or product that needs to be machined, allowing manufacturers to accurately produce the desired outcome.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining.

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders.Providing a technical drawing can help you source better parts and even reduce your costs. In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing.

machine parts drawing with dimensions

There are several components that are part of technical drawings. Among the most important components are the title block, the isometric view, the orthographic view, the coordinates, the section view, and the detail view.

Technical drawing involves the use of various tools and techniques to accurately and precisely create diagrams, blueprints, and other visual representations of mechanical or architectural designs. Here, I will take a brief look at some key components of technical drawings for CNC machining.

Learn more about the different parts of a CNC machine and their functions. CNC (computer numerical control) machines are complex pieces of equipment designed to automatically manufacture parts from a wide range of materials that .

create cnc file from drawing

cnc turning machine drawing

My plan was to mount the junction box on the back wall of the cabinet in the bottom drawer location, and that's still an option, but it takes me a fraction of an inch too far forward to use 21 inch drawer runners, and the next size down is 18 inches.

cnc drawing machine parts|2d drawing and cnc turning