junction box in use As a rule, your junction box should have approximately one meter of clearance on all sides. If your movement is limited, it is going to be difficult to access the junction box. This can make a bad problem much worse. Finally, . Have you ever stopped to ponder how metal is shaped, formed, and treated? That broad definition can be summed in three words: metal .

0 · why are junction boxes used

1 · where are junction boxes located

2 · residential junction box

3 · junction box vs receptacle

4 · junction box for electrical wiring

5 · junction box explained

6 · function of junction box

7 · different types of junction boxes

Our Metal Corner Braces and Brackets protect and strengthen corner ends while adding a decorative touch. We offer a variety of different finishes and shapes, including Square, Wide, and Offset, to meet the needs of any project.

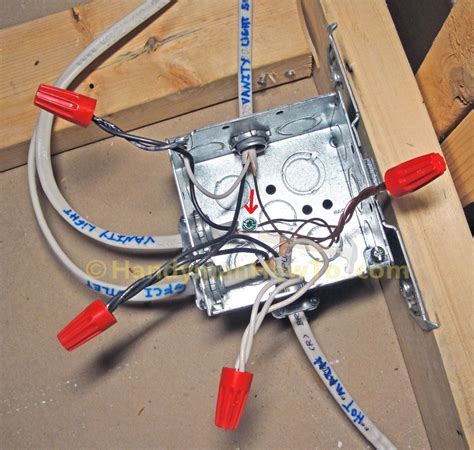

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. This electrical box functions as a junction box. However, a junction box is NOT an electrical box. There must be a junction box protecting those connections if there is no electrical box. If changes are made often, the . What determines where junction boxes are included in the plans for wiring a new house? If it's desirable to have a continuous run of wire from the breaker box to an electrical device, then that's a reason for avoiding junction boxes. But I'd think that future modifications to wiring in a room would be easier if a junction box was handy. As a rule, your junction box should have approximately one meter of clearance on all sides. If your movement is limited, it is going to be difficult to access the junction box. This can make a bad problem much worse. Finally, .

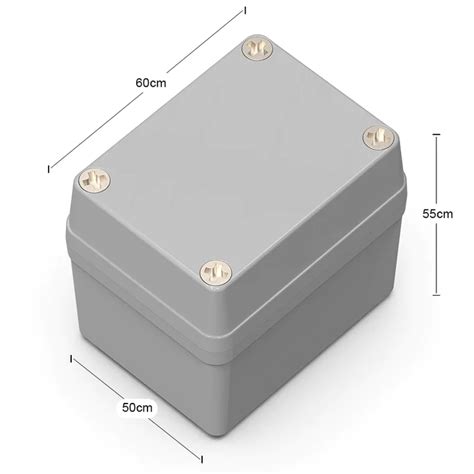

A 4-inch square junction box is exactly what it sounds like: It's 4 inches in size all the way around. These junction box types are primarily used for conductors that are split in two or more directions, per Polycase. Similar to a standard junction box, a 4-inch square junction box is typically best for standard light switches and outlets.

Although building codes allow junction boxes in crawl spaces and attics, they impose strict regulations and installation standards on them to prevent the risk of electrical fires and shocks.Putting a junction box in places like a crawl space is risky, especially if you place them right under the shower.Building code says that the junction box should be immediately . Install junction boxes properlyKreg pocket hole jig: https://amzn.to/3R8XbO8Milwaukee M12 power screwdriver: https://amzn.to/4bMei0a(affiliate links)Video on.

Install a dedicated junction box: Use a junction box specifically designed for the application, ensuring compliance with NEC requirements and safety standards. Use a wiring connector or splice : Select a wiring connector or splice that meets NEC requirements and is suitable for the specific application. Why would I choose a large 4x4x2.5 metal box (this is what my brain tells me to use) vs plastic box. The plastic looks like they are all designed for installing switches or outlets and not covers but they are larger and cheaper. Is there a reason why one would not just use the plastic box and cover for a junction box either in an attic or basement. Correct fill capacity: The junction box should be large enough to contain the wires. Many DIYers choose the largest box practical for the application. To stay within code-approved limits, though, consult a fill capacity chart. Plastic vs. metal boxes: Use a metal junction box with metal-sheathed cable (also called BX cable), for proper .Junction boxes merely need to be "accessible", whereas breaker panels have to be "readily accessible". A junction box in an unfinished attic would be "accessible" for NEC purposes since one can access it without altering the building structure or finish. Of course if one were to later finish the attic one would have to make sure not to bury any .

why are junction boxes used

The boxes are required by code for a reason. If, over years, the connection should become loose, it could arc, and spark. If its in a box, that's not goid, but not disastrous. If its not in a box, it could cause a house fire. Use a box, follow the code.110.3 says it needs to be listed for the application, and much the same as other junction boxes, there's not much in the way of excluding making your own holes 314 says in order to use it as a junction box that contains splices the body has to be stamped with the amount of cubic area, but that doesn't exclude making holes in the side and adding .You can use the existing junction box that you have there for the cable, assuming that junction box is for another circuit, you can either add another receptacle since it is a square box or break both taps in the existing receptacle and one half is one circuit and the other half is the other circuit. The junction box can be either plastic or metal.

Also, what is the best place to put the junction boxes in the attic? I assume off the floor on a stud? Save Share Reply Quote Like. Sort by Oldest first Oldest first Newest first Most reactions. joed. 27488 posts When cutting off wires coming out of a junction box, you must go into the box and remove the wires from their wire nut splices. Otherwise the cut off wire ends will be energized (and 1/8" apart, what could go wrong? LOL) . Where the opening to an outlet, junction, or switch point is less than 200 mm (8 in.) in any dimension, each conductor shall be long enough to extend at least 75 mm (3 in.) outside the opening Exception: Conductors that are not spliced or terminated at the outlet, junction, or switch point shall not be required to comply with 300.14.If you use BX, you need to use a metal junction box. There's a couple different types of boxes. The plastic ones with nails on them, and the metal ones with clips are designed to mount with their face 1/2" farther out than the front, which .

If any new wires need to be pulled in the future and there are other hidden junction boxes in the wall, say goodbye to a lot of drywall, and hello to re-doing said drywall and re-painting, plus all the expenses. Unless the electrician is also the drywaller, I would say this is the drywaller’s fault for burying it, unless there was a cover .

Electrical - AC & DC - Plastic versus metal junction box in attic with insulation - I have been trying to diagnose a faulty circuit in my house and spent time in the attic ploughing through the insulation. I found a single wire from the panel spliced to two wires. The splice is wrapped in electrician tape and

In my area of the world, junction boxes are allowed provided they remain accessable. However, the code is silent on how heavy a wire can be spliced using a junction box. I get a bit nervous when the amperage gets up to 40 and the voltage is 240. In the short term, I am sure that it will work but time and corrosion can take a toll. Mount the junction box on the wall. Always use the designated holes or brackets on the junction box to secure it to the wall. Many junction boxes come packaged with the proper fasteners. They can be screwed onto wall studs or ceiling joists.

metal fabrication reading pa

Bud offers thousands of models of box electrical enclosures suited for use as junction boxes, both indoors and outdoors. Choose a box in the size you need based on the type of material (steel, diecast aluminum, plastic, or fiberglass) you prefer. Consider features such as hinged covers, screw-down covers, transparent covers, and knockouts. . The proper installation and use of junction boxes are paramount for a safe and efficient electrical system in your home. By understanding the function of junction boxes, using the right tools and materials, following a step-by-step guide, and avoiding common mistakes, DIY enthusiasts can tackle wiring projects with confidence. We use junction boxes of different sizes in residential and commercial areas. The shape of junction boxes also matters according to the number of wires. The type of junction and junction box used depends on the specific application, with box size varying to accommodate different wiring needs.

metal fabrication regina

N2 - Engineering robust adhesion of the junction-box (j-box) is a hurdle typically encountered by photovoltaic (PV) module manufacturers during product development and manufacturing process control. There are historical incidences of adverse effects (e.g., fires), caused when the j-box/adhesive/module system has failed in the field.Weather proof junction box, with the pigtail and ethernet cable meeting inside the box. Drill a larger hole (minimum 3/4") in the building you're mounting it to, and stuffing the pigtail into the wall cavity. You could just leave the cords exposed, but protect it some other way.The Junction Box is a mechanism that allows wires of the same color to cross without connecting. It is purchased from the Mechanic for 2. The Junction Box can be placed in midair, without the need for support. Hammering the Junction Box changes the directions that the different colored wires enter and exit the Junction Box. The Junction Box can be used as an alternative to .

where are junction boxes located

residential junction box

We have compiled a short breakdown of each of the grades’ properties in order to provide you with a brief understanding of their many uses. Alloy 1100: This grade is commercially pure aluminum. It is soft and ductile and has excellent workability, making it ideal for applications with difficult forming.

junction box in use|residential junction box