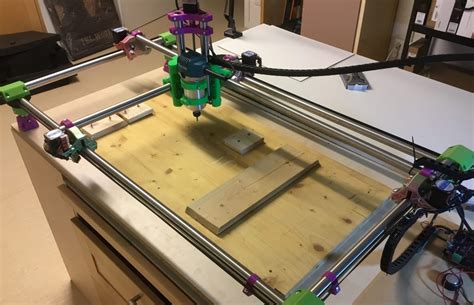

diy cnc machine wood Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting . True Board and Batten Vertical Steel Siding is a favorite for post-frame buildings, farmhouses, and barndominiums. Our metal siding is available in a 10" reveal profile. Each 10-inch vertical board and batten siding piece is 10ft. long. Custom lengths may be .

0 · make your own cnc mill

1 · make your own cnc machine

2 · do it yourself cnc machine

3 · diy woodworking cnc

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build your own cnc mill

$209.00

make your own cnc mill

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting .

make your own cnc machine

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress .

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __

In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show .

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts.

Rather than cutting metals like CNC mills, DIY CNC routers use less powerful routers as spindles to cut wood, as well as soft aluminum, plastics, foams, and sometimes glass. These tools let hobbyists embark on projects like:

do it yourself cnc machine

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisMost homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange. Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show you how to build a CNC router.

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC. A chop saw, wood lathe, drill and a drill press, and finally a table saw — nothing fancy, but now with the CNC router he has a world of possibilities for projects!Building this huge CNC router for woodworking from a CNC build kit was super fun. I show you how I've assembled it as well as the spoilboard setup and explai.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts.

Rather than cutting metals like CNC mills, DIY CNC routers use less powerful routers as spindles to cut wood, as well as soft aluminum, plastics, foams, and sometimes glass. These tools let hobbyists embark on projects like:Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisMost homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange. Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __

In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show you how to build a CNC router.DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

A chop saw, wood lathe, drill and a drill press, and finally a table saw — nothing fancy, but now with the CNC router he has a world of possibilities for projects!

cnc machining service product

diy woodworking cnc

diy cnc machine for woodworking

building your own cnc router

$52.99

diy cnc machine wood|building your own cnc machine