can cnc machine cut metal CNC machines have revolutionized metal cutting, offering numerous advantages over traditional methods. Here's how CNC technology empowers metal fabrication: Unmatched Precision and Accuracy: CNC machines utilize .

Benefit from a second key, which can be used by co-owners or as a backup set in case of loss/misplacement. ADJUSTABLE SHELF HEIGHT: Four of the five shelves in this cabinet are adjustable, guaranteeing maximum adaptability and convenience for your own unique storage and organizing needs.

0 · industrial metal laser cutting machine

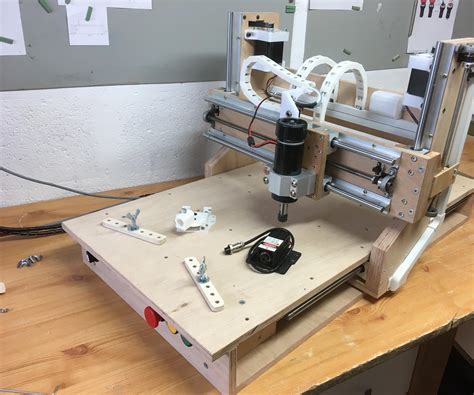

1 · hobby cnc machine for metal

2 · cnc metal cutting machine price

3 · cnc laser cutter near me

4 · cnc cutting machine near me

5 · best metal cutting cnc machine

6 · affordable metal cutter router

7 · affordable cnc machine for metal

B-Line series electrical Type 3 and 3R junction boxes are used as wiring boxes, junction and pull boxes. For additional information, view or download the Type 3 and 3R enclosure section of the B-Line series electrical enclosure catalog. Explore other Eaton solutions.

CNC machines can cut metals like steel, aluminum, and copper. However, metals are hard materials, and not all CNCs can cut metal. The ability of a CNC machine to cut metal depends upon factors such as its rigidity, .

CNC machines achieve remarkable precision in metal-cutting operations. Standard tolerances reach ±0.001 inches (0.025mm) for most applications. High-precision machines can achieve even tighter tolerances . In short, the answer is yes. CNC machines are capable of cutting a wide variety of materials, including metals like steel, aluminum, and brass. CNC routers are typically used to cut and carve non-ferrous metals like aluminum and brass. These machines use specialized bits to remove material from the workpiece, and they rely on numerical code to feed the metal . Machining metals, including steel using a CNC router, is possible with heavy duty and powerful industrial CNC routers. One can easily cut steel by matching the material with the appropriate feed rate and the right end mill bit.

CNC machines have revolutionized metal cutting, offering numerous advantages over traditional methods. Here's how CNC technology empowers metal fabrication: Unmatched Precision and Accuracy: CNC machines utilize .CNC machines utilize several techniques for cutting metal, each offering unique advantages tailored to specific applications. These techniques include milling, plasma cutting, and laser .

CNC machines are capable of cutting metal with high precision and accuracy. Choosing the right metal for CNC machining depends on various factors such as required properties and cost. CNC milling and turning are . Using a CNC machine for metal is much like using a CNC router for woodworking or any other task. However, not all CNC routers are designed to work with metal and may not .

CNC machines can cut metals like steel, aluminum, and copper. However, metals are hard materials, and not all CNCs can cut metal. The ability of a CNC machine to cut metal depends upon factors such as its rigidity, spindle power, the cutting tool used, and the machinability of the metal.

CNC machines achieve remarkable precision in metal-cutting operations. Standard tolerances reach ±0.001 inches (0.025mm) for most applications. High-precision machines can achieve even tighter tolerances when needed. In short, the answer is yes. CNC machines are capable of cutting a wide variety of materials, including metals like steel, aluminum, and brass. In this article, we’ll discuss two main types of machines: CNC routers (which can cut soft metals like aluminum) and CNC metal mills (designed to handle harder metals like steel, stainless steel, brass, titanium, magnesium, and more.)

CNC routers are typically used to cut and carve non-ferrous metals like aluminum and brass. These machines use specialized bits to remove material from the workpiece, and they rely on numerical code to feed the metal workpiece to a cutting tool. Machining metals, including steel using a CNC router, is possible with heavy duty and powerful industrial CNC routers. One can easily cut steel by matching the material with the appropriate feed rate and the right end mill bit.CNC machines have revolutionized metal cutting, offering numerous advantages over traditional methods. Here's how CNC technology empowers metal fabrication: Unmatched Precision and Accuracy: CNC machines utilize computer-controlled tools, guaranteeing consistent and precise cuts on every piece.CNC machines utilize several techniques for cutting metal, each offering unique advantages tailored to specific applications. These techniques include milling, plasma cutting, and laser cutting, enabling precise and efficient fabrication.

CNC machines are capable of cutting metal with high precision and accuracy. Choosing the right metal for CNC machining depends on various factors such as required properties and cost. CNC milling and turning are popular types of . Using a CNC machine for metal is much like using a CNC router for woodworking or any other task. However, not all CNC routers are designed to work with metal and may not all offer the results you desire. CNC machines can cut metals like steel, aluminum, and copper. However, metals are hard materials, and not all CNCs can cut metal. The ability of a CNC machine to cut metal depends upon factors such as its rigidity, spindle power, the cutting tool used, and the machinability of the metal. CNC machines achieve remarkable precision in metal-cutting operations. Standard tolerances reach ±0.001 inches (0.025mm) for most applications. High-precision machines can achieve even tighter tolerances when needed.

In short, the answer is yes. CNC machines are capable of cutting a wide variety of materials, including metals like steel, aluminum, and brass. In this article, we’ll discuss two main types of machines: CNC routers (which can cut soft metals like aluminum) and CNC metal mills (designed to handle harder metals like steel, stainless steel, brass, titanium, magnesium, and more.)

CNC routers are typically used to cut and carve non-ferrous metals like aluminum and brass. These machines use specialized bits to remove material from the workpiece, and they rely on numerical code to feed the metal workpiece to a cutting tool. Machining metals, including steel using a CNC router, is possible with heavy duty and powerful industrial CNC routers. One can easily cut steel by matching the material with the appropriate feed rate and the right end mill bit.CNC machines have revolutionized metal cutting, offering numerous advantages over traditional methods. Here's how CNC technology empowers metal fabrication: Unmatched Precision and Accuracy: CNC machines utilize computer-controlled tools, guaranteeing consistent and precise cuts on every piece.CNC machines utilize several techniques for cutting metal, each offering unique advantages tailored to specific applications. These techniques include milling, plasma cutting, and laser cutting, enabling precise and efficient fabrication.

CNC machines are capable of cutting metal with high precision and accuracy. Choosing the right metal for CNC machining depends on various factors such as required properties and cost. CNC milling and turning are popular types of .

industrial metal laser cutting machine

unitek gemini metal brackets mbt 3 hook 5-5

In junction boxes, deflecting the cables not less than 90 degrees and carrying them horizontally to a distance not less than twice the diameter of the cable, the cables being carried on two or more insulating supports and additionally secured thereto by tie wires, if desired.

can cnc machine cut metal|industrial metal laser cutting machine