broaching cnc machine Our CNC Broaching Kits are designed to conveniently give you a wide range of capabilities for your applications at a better value than buying individually. These kits contain our CNC Broaches, inserts and torx drivers in a convenient metal . By paying attention to welding parameters and joint design, welders can actively work to prevent/minimize warping in stainless steel welding, ensuring strong, distortion-free welds that meet the highest standards of quality and reliability.

0 · what is broaching cnc machining

1 · cnc broaching tool company

2 · cnc broaching tool

3 · cnc broaching process

4 · broaching tool for cnc mill

5 · broaching tool for cnc lathe

6 · broaching on cnc lathe

7 · broaching on a cnc mill

$46.09

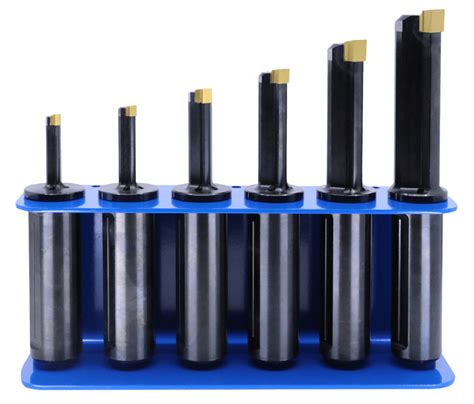

Our CNC Broaching Kits are designed to conveniently give you a wide range of capabilities for your applications at a better value than buying individually. These kits contain our CNC Broaches, inserts and torx drivers in a convenient metal .

The duMONT CNC Indexable Broaching System was developed to execute internal hexagons. It offers the following advantages: absolute concentricity, the possibility of correcting the required measurement, machining speed and cost savings.

what is broaching cnc machining

cnc broaching tool company

Broaching (Slotting) is a machining process in which a keyway or a profile is created by cutting movements on the Z-axis. The cutting depth is determined with movements of the X-axis. With the working stroke on the Z-axis, material is .Our CNC Broaching Kits are designed to conveniently give you a wide range of capabilities for your applications at a better value than buying individually. These kits contain our CNC Broaches, inserts and torx drivers in a convenient metal rack for simple storage and use. Analogous to the multiple passes of a shaper, a relatively new class of CNC tooling and programming allows broaching operations to be done without the need for a second operation, thus greatly increasingly quality control and reducing time, space and cost.Discover high-quality broaching tools designed to deliver efficient cutting performance and precise results. Our inserts are engineered for durability and optimal chip control, ensuring smooth operations in CNC milling and turning.

Maximize productivity: All of our cnc broaching machines include indexable heads and quick-change broaches and cutters so you can work faster. Minimize downtime: We use quality materials and components in our CNC broaching machines .The duMONT Minute Man® CNC Broaching System allows the cutting of through and blind hole keyways, keyways in a tapered bore and shaped or splined holes. A chamfer at the intersection of the bore and the wall of the keyway slot is also an available feature. The benefits of broaching on a CNC machine include fast speeds to create final forms, high accuracy, low heat, high repeatability and easy operation utilizing standard drilling G code. Broaching on a CNC machine also eliminates the need for secondary operations, such as wire EDMing, Derbin said.CNC Lathe broaching and CNC mill broaching are great methods of completing the slotting process and avoiding the cost other expensive Broaching Systems. This guide will walk you through the basic steps of what it takes to get a CNC machine broaching your parts.

Keyway broaching (keyway slotting, key slotting) is an essential machining process used to create internal slots or keyways in a workpiece, such as a gear. These keyways enable the transmission of torque between the workpiece and a coupling component, such as a shaft.The duMONT CNC Indexable Broaching System was developed to execute internal hexagons. It offers the following advantages: absolute concentricity, the possibility of correcting the required measurement, machining speed and cost savings. Broaching (Slotting) is a machining process in which a keyway or a profile is created by cutting movements on the Z-axis. The cutting depth is determined with movements of the X-axis. With the working stroke on the Z-axis, material is .

Our CNC Broaching Kits are designed to conveniently give you a wide range of capabilities for your applications at a better value than buying individually. These kits contain our CNC Broaches, inserts and torx drivers in a convenient metal rack for simple storage and use. Analogous to the multiple passes of a shaper, a relatively new class of CNC tooling and programming allows broaching operations to be done without the need for a second operation, thus greatly increasingly quality control and reducing time, space and cost.Discover high-quality broaching tools designed to deliver efficient cutting performance and precise results. Our inserts are engineered for durability and optimal chip control, ensuring smooth operations in CNC milling and turning.

Maximize productivity: All of our cnc broaching machines include indexable heads and quick-change broaches and cutters so you can work faster. Minimize downtime: We use quality materials and components in our CNC broaching machines .The duMONT Minute Man® CNC Broaching System allows the cutting of through and blind hole keyways, keyways in a tapered bore and shaped or splined holes. A chamfer at the intersection of the bore and the wall of the keyway slot is also an available feature. The benefits of broaching on a CNC machine include fast speeds to create final forms, high accuracy, low heat, high repeatability and easy operation utilizing standard drilling G code. Broaching on a CNC machine also eliminates the need for secondary operations, such as wire EDMing, Derbin said.CNC Lathe broaching and CNC mill broaching are great methods of completing the slotting process and avoiding the cost other expensive Broaching Systems. This guide will walk you through the basic steps of what it takes to get a CNC machine broaching your parts.

cnc broaching tool

cnc broaching process

broaching tool for cnc mill

broaching tool for cnc lathe

broaching on cnc lathe

Contact - Wenger Construction | Roofing | Siding | Sheet Metal

broaching cnc machine|broaching tool for cnc lathe