sheet metal finishing processes Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .

By 2033, the global electrical enclosures market size is expected to reach US$ 10.8 billion by 2033. Key Trends Shaping the Market: Cabinets or boxes used for housing electrical or electronic equipment to protect them from external damages as well as to prevent electrical shock to equipment users are known as electrical enclosures.

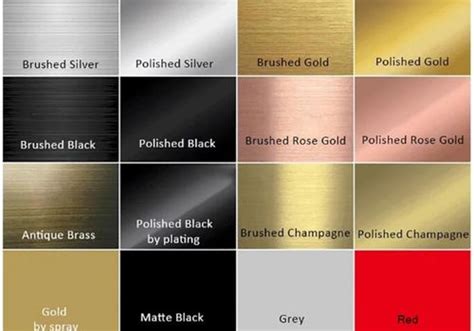

0 · types of metal surface finishes

1 · types of metal finish chart

2 · types of finishes for metal

3 · how to smooth metal surface

4 · finishing techniques for metal

5 · different types of metal finishing

6 · different finishes on metal

7 · all type metal finishing

16-Gauge stainless steel: premium 16-gauge thickness and type 304 stainless steel for immense durability, performance and lustrous beauty. Quiet: sound-deadening materials minimize sound and vibration for a quieter time at the sink

Discover various sheet metal finishing options to enhance durability and aesthetics. Explore metal finishing techniques for your sheet metal fabrication needs today! This section will introduce the different sheet metal finishing processes you can add to your sheet metal design plan. This will include a short mechanism of action, uses, .Metal finishing transforms raw sheet metal surfaces into refined, protected components. These specialized processes enhance durability, improve appearance, and add crucial performance . Through different processes such as grinding, polishing, coating, or plating, metal surface finishing improves corrosion resistance and can enhance the look and function of metal components. Various finishing processes .

Metal plating is the process of changing the surface of a substrate by covering it with thin layers of another metal such as zinc, nickel, chromium or cadmium. Metal plating can improve the durability, surface friction, corrosion .Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .

In this comprehensive guide, we review three popular metal finishing techniques: painting, powder coating, and silk screening, looking at specific applications and key considerations for choosing both a metal . 1. What Is Sheet Metal Finishing? 2. Why Do You Need Sheet Metal Finishing? 3. Sheet Metal Finishing Techniques; 4. How to Select the Right Sheet Metal Finishing Process; 5. Final Word

types of metal surface finishes

Stevenage Sheet Metal has created a supply chain combining the specialist services of quality audited partners who provide engineering and finishing processes matching our own rigorous standards. We offer customers .Powder Coating Finishing. We offer a variety of powder coating options, including different colors, textures, and finishes, allowing for customization and flexibility in design. . The sheet metal powder coating process involves several key steps to ensure a successful and durable coating. Here is an overview of our typical processes involved:Metal surface treatment allows you to enhance your product’s appearance, performance and lifespan. The Komacut platform simplifies obtaining sheet metal parts with your preferred surface finishing at mass production quality and pricing by offering a range of standard metal surface treatments, in a variety of colors and finishes.Simply upload your drawings to receive instant .

1. What Is Sheet Metal Finishing? It is the final stage of the sheet metal fabrication process. In other words, after all the cutting, turning, drilling, and other manufacturing techniques needed to make a functional part from a workpiece, finishing is due.

No matter what the reason, each of these eight metal surface finishing processes plays an important role in the manufacturing process: Electroplating – This process forms a thin metallic coating on the substrate. The electroplating process passes a positively-charged electrical current through a solution containing dissolved metal ions and a . Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. . Chrome Plating vs. Powder Coating: Powder coating is a dry finishing process that creates a thick, protective layer on the surface. It’s known for its color variety and environmental benefits, as it emits .Sheet metal finishing is a crucial aspect of the manufacturing process that transforms raw metal sheets into high-quality products with impeccable surface finishes. The process of metal surface finishing involves various techniques and technologies designed to enhance both the appearance and functionality of sheet metal components of various .Sheet metal fabrication processes. Sheet metal fabricators produce metal parts and structures from metal sheets using numerous operations and processes. These operations are classified into the following: Cutting; Forming; Joining and assembly; Post-processing and finishing; The application of these processes may vary by project.

wastewater from the electrowinning process will still need to be treated for metal but the metal content will be much lower and therefore cost less to treat and cost less for sludge disposal since the sludge volume will be much reduced.This sheet metal finishing process allows for the use of custom designs without size or color restrictions, like for adding customer logos, part labels, or permanent legends to control panels. For printing high-quality images on flat sheet metal surfaces; Accommodates bare metal, stainless steel, and painted or coated metals How To Choose The Right Metal Finishing Process For Your Project. Metal finishing encompasses a wide array of processes designed to enhance the surface properties of metal components. From enhancing corrosion resistance to achieving a specific aesthetic finish, selecting the appropriate method is paramount for ensuring the desired functionality .

Sheet metal finishing is always an interesting process. As experts, we can say that it comes with a lot of practice, and it helps us stand out from other metal fabricators. Call Us : 425-258-4614 The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms. . It is a finishing operation by removing the burrs from the cut . Top Sheet Metal Finishing Options 1. Powder Coating. Powder coating is one of the most popular finishing options for sheet metal. In this process, a dry powder (usually made from polymers) is electrostatically applied to the metal surface. The coated part is then cured in an oven, where the powder melts and forms a tough, protective layer.

Alternative Sheet Metal Finishing. There are several other methods that are utilized to finish sheet metal parts, and the finishing process selection depends on the environmental conditions, assembly, function, and .

Metal Finishing Processes . High-Precision Metal Sheet Bending. METECHWORKS stands at the forefront of sheet metal processing, leveraging extensive expertise and advanced technology, including multiple CNC bending machines ranging from 40to120 to tons. We deliver comprehensive, one-stop solutions that encompass material forming, welding, CNC .

When metal is cut or stamped, it creates sharp edges called burrs. Even though they are small, burrs can cause assembly problems, interfere with fluid flow, cause worker injury, and can also cause increased stresses and .In metal fabrication, fabricators create metal parts from raw source metals like steel, copper or aluminium.They’ll use methods like cutting, punching, bending, and welding to fabricate the parts needed for a project. Sheet metal fabrication specifically uses all of the same processes, but only flat metal sheets are used as the source to create the products. Forming and Finishing. The core of sheet metal forming is the actual shaping process, where tools and machinery apply force to bend, stretch, and press the metal into desired shapes. Common techniques include bending, stamping, and drawing, each chosen based on the shape complexity and the type of metal used. . Drawing refers to the process .

The metal fabrication process– The sheet metal fabrication process involves cutting, bending, welding, forming, joining, and finishing. Product finishing– After fabrication of the component is complete, a product has to undergo the product finishing steps like sandblasting, brushing, polishing, powder coating, plating, etc. After this step . Listed below are some of the more common finishing processes specifically used on sheet metal parts. Many of these surface finishes offer improved corrosion resistance. Corrosion resistance is a general term, however, and an .

types of metal finish chart

3 6 Tips for Designing Powder Coated Sheet Metal Parts. 3.1 POWDER COATING; 3.2 Consolidate Your Supply Chain with Approved Sheet Metal; 4 Sheet Metal E-Coat and Black Oxide FAQ. 4.0.1 Why are e-coat and black oxide treatments no longer popular in metal fabrication? 4.0.2 What drawbacks did black oxide and e-coat finishing processes present?

What is metal finishing? Metal finishing refers to a variety of treatments or processes that range from polishing to processes that affect a metal’s molecular structure. Metal finishing includes a variety of cleaning treatments, polishing methods, and other operations designed to improve and enhance the surface of a given metal product. Streamlining the process of sheet metal assembly, where accuracy and repeatability foster the fabrication of intricate and complex sheet metal components, is essential when serving leading manufacturers in today’s most important industries. . Finishing: To enhance the appearance and protect the product against corrosion, finishing touches . Discover the various processes of sheet metal fabrication. From cutting and bending to finishing and assembly, explore over 50 techniques and boost your knowledge.

There are many different choices to make when using sheet metal to fabricate a product. Decisions have to be made at the design stage, choices such as material selection, material thickness or what kind of finish is required.As part of the design process, it’s important to consider which production technologies might be used when manufacturing the part, and .Finishing. Aluminum can be finished through a variety of processes including powder coating and anodizing, which enhances its natural oxide layer, providing increased corrosion resistance and allowing for dyeing the metal in different colors. . Galaxy offers sheet metal fabrication services since 1989, with a comprehensive range of in-house .

used cnc milling machine for sale uk

types of finishes for metal

Fast and affordable metal fabrication for commercial and residential projects. Wall Panels, Metal Shingles, ACM, Metal Roofing & Gutter Systems and Much more. Hire United Metal Construction (UMC) to take care of your next project starting .

sheet metal finishing processes|types of finishes for metal