cnc machining process parameters Industry and industrial production, technologies, materials, and equipment in use are advancing very rapidly. In addition to CNC technologies, which represent traditional manufacturing technologies, one of the technologies that is gaining ground is certainly 3D printing. 3D printing is a generally faster, cheaper, and easier solution than other technologies for the . Instead, everything you need to deposit a weld comes from a spool of metal wire. In this welding process, more popularly known as MIG, a gas tank (typically CO2 or argon) provides the shielding while the wire melts into the base metal.

0 · cnc parameters explained

1 · cnc parameters examples

2 · cnc parameter settings

3 · cnc machining parameters list

4 · cnc machining parameters explained

5 · cnc cycle parameters

6 · best cnc parameters

7 · 7 cnc parameters

There are several types of junction boxes, each designed for specific purposes: These are commonly used in industrial settings due to their robustness and durability. They are excellent for protecting electrical connections in harsh environments. Plastic junction boxes are prevalent in residential and commercial settings.

By understanding the types of CNC machine parameters, the factors influencing parameter settings, the steps for setting them, the recommended parameters for different .Learn about the essential parameters of a CNC machine, from spindle speed to cycle time, to maximize efficiency and precision in your machining operations.

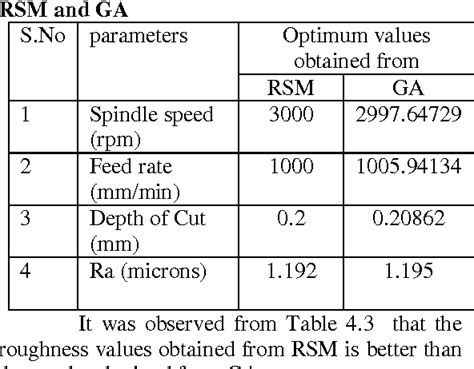

Machining process parameters (MPP) directly affect the machining quality and efficiency of heavy-duty CNC machine tools (HCMT). The selection of MPP is very important to effectively improve machining performance. Machining performance has been closely related to the HCMT running state. In order to maintain HCMT sustainably manufacturing with high . Industry and industrial production, technologies, materials, and equipment in use are advancing very rapidly. In addition to CNC technologies, which represent traditional manufacturing technologies, one of the technologies that is gaining ground is certainly 3D printing. 3D printing is a generally faster, cheaper, and easier solution than other technologies for the . Identifying and selecting optimal cutting parameters in a machining process is essential to increasing productivity in terms of dimensional accuracy . corrosion and high temperature, and good machinability (50%). When it comes to CNC machining of nickel-aluminum bronze, there are several things you must keep in mind due to its complex . The effective machining parameters such as depth of cut, feed rate and spindle speed in turning operations are investigated to minimize the surface roughness as well as time of machining process .

Calculating the CNC machining time and overall lead times is more than a procedural step; it’s a strategic tool essential for modern manufacturing processes. When you understand how long each component takes to produce, you’re better equipped to optimize operations and promise realistic delivery schedules to your customers.

The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools. This allows factories to produce parts accurately and at a rapid pace, making it an ideal solution for intricate designs and high-volume production. . The cutting speed is a crucial parameter .

There process parameters in machining are all those parameters that are inherent to any machining operation and should have a suitable finite value to smooth and efficient removal of materials. Such parameters directly affect machining performance. In machining, three process parameters are (i) cutting speed or cutting velocity, (ii) feed rate . Machining process simulation is a method to increase machining quality and efficiency. The right cutting tool geometry and parameters are chosen during the machining simulation process to create a variety of precision component shapes. A machining simulation for the production of polygonal shafts is presented in this paper. The quality of the parabolic shaft . EN8 is a well-known grade of medium carbon steel, which is casually machinable in any condition. Objective of this work is to optimize milling parameters of EN8 steel, which is focused toward the increasing MRR, cutting force minimization produced during machining and to minimize the surface roughness of machined parts.

Determine parameters related to feed; For automatic programming of machining complex surfaces, five feed speeds must be set (1) High-speed channel speed (empty feed rate) To save non-cutting time, G00 speed, the maximum feed speed allowed by the machine tool, is usually selected. (2) Bottom edge speed (close to the workpiece surface feed speed) In order . To remain competitive, machining processes must be optimized to provide increased productivity and higher quality products. The aim of most efforts in these machining processes is to establish the optimal parameters to obtain the maximum material removal rate with minimum surface roughness which represents two of the main quality responses.

CNC is the advanced industrial equipment to meet different machining requirements. In this blog, we will discuss the cutting parameters for CNC machines. [email protected]. 866.262.6233 REQUEST A QUOTE. HOME; CAPABILITIES. . The material and the process often decide the cutting speed. For example, grooving requires slower cutting .

How to optimize the process parameters in the machining process of CNC machine tools is an urgent basic scientific problem to be solved under the background of green manufacturing . Traditional research on process parameters optimization mainly aims at optimizing the quality, cost and efficiency of the process. . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Each machine has its own advantages and .

CNC Turning, or Computer Numerical Control Turning, is an important part of modern CNC machining processes and operations.This technology harnesses the precision of computer programming to manipulate . The processing parameters have a particularly significant impact on the quality and efficiency of processing. Selecting the correct processing parameters can greatly improve the processing performance of the machine tool. To this end, by improving the chromosome structure and genetic operators of the GA algorithm, a new GA-BP neural network algorithm is proposed .

There are a large number of low rigidity parts in the aerospace field, and how to achieve high-performance manufacturing in their multistage machining processes has received increasing attention. Optimizing the distribution of machining allowance and machining parameters is one of the most convenient ways to improve the machining performance of .Computer numerical control (CNC) machine tools are widely used in the manufacture of precision parts in aviation, aerospace and other fields due to their advantages of automation and precision (Liu et al., 2022a, 2022b, 2022c).With the continuous improvement of product quality requirements of users, it is very urgent to improve the machining accuracy of CNC machine tools.

cnc parameters explained

When planning a CNC machining process there are many considerations and options to choose. From cutting tool selection to cutting parameters, the choices have a major effect on the end results. Here is what it might take to define a CNC toolpath: O.B Aboueletta et al [1] has conducted experiments on turning operation of mild steel shaft and estimated the correlation between the cutting parameters and machine tool vibrations. The work contained the parameters like rotational speed, feed rate, depth of cut and tool variables like tool nose radius, tool overhang and approach angle and work piece . 1. The principle of choosing CNC tools Tool life is closely related to cutting volume. When formulating cutting parameters, the reasonable tool life should be selected first, and the reasonable tool life should be determined according to the optimization goal. Generally divided into the highest productivity tool life and the lowest cost tool life, the Quality control in CNC machining is a process of using instruments and techniques that ensure a high-quality output that meets industry standards and regulations. It is one of the key factors for a successful manufactured product. . Quality Control Parameters in CNC Machining. CNC machines rely on crucial parameters, such as computer .

The objective of this study was to demonstrate that an ENN can optimise a CNC machining process by identifying input parameter permutations that maximise MRR when constrained on SR and DoC. Although the results presented in this study satisfy the objective, the modelling framework did not account for tool wear during the optimisation process.In this comprehensive guide, we will walk you through the step-by-step process of CNC machining, exploring each stage in detail. . This includes ensuring the cutting tools are correctly installed, the workpiece is securely attached, and the CNC machine's parameters and settings are adjusted according to the material and design requirements. Parameters Of Quality Control In CNC Machining. . What are the main steps involved in CNC machining? The process consists of three essential stages. Firstly, a CAD program is employed to develop CAD 3D models. Next, the computer is integrated into the CNC program and configured. Finally, the machine utilizes materials from the workpiece to . In CNC machining, the precision and quality of the machined parts are significantly influenced by various machining parameters. These include cutting speed, feed rate, and depth of cut, each playing a crucial role in the outcome of the machining process.

In CNC machining process used to upgrade the efficiency and output parameters compare with the manual methods like manually and semi-automatic lathe. Product quality is mainly based on the surface roughness of the output product. . Gilbert 1950 the paper deal with the optimisation of machining parameters in turning process which is used to .

gag sheet metal new ulm

futuristic junction box

Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

cnc machining process parameters|cnc cycle parameters