sheet metal soft tooling vs hard tooling While soft tooling is ideal for perfecting a mold or prototype, hard tooling is the process you’ll need when it comes time to finalize a product and produce larger batches. With hard tooling molds, you can stamp, machine, . General information on 401(k) plans. Starting up your plan. What to know before adopting a plan. Plan qualification requirements. Language needed in your plan. Contribution limits. 401(k) plan contribution limits, catch-up contributions and .

0 · soft tooling vs hard tools

1 · soft tooling injection molding

2 · soft tolling

3 · soft mold

4 · sheet metal soft tooling vs hard

5 · sheet metal soft tooling

6 · sheet metal hard tooling

7 · hard tooling vs hard tools

So, here we’ve gathered a list of CNC projects that make great starter projects for anyone new to machining. We’ve sorted them from what we think are the easiest projects to the hardest ones. There’s sure to be .

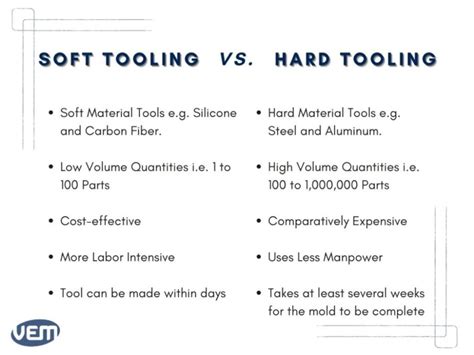

If speed, flexibility, and affordability are top priorities, soft tooling might be the better option. If a parts manufacturer has a set blueprint with which to build a highly precise product and can foot the additional expense and labor .

While soft tooling is ideal for perfecting a mold or prototype, hard tooling is the process you’ll need when it comes time to finalize a product and produce larger batches. With hard tooling molds, you can stamp, machine, . Sheet metal soft tooling is easy, gives low volume run, is cost-effective, and good for prototypes but gets wear easily and is less precise. Hard tooling involves large initial costs, difficult machining, and large production .Lead time: If the project demands a fast turnaround, soft tooling offers the advantage of quicker production, allowing for more rapid iterations and adjustments. Part complexity: Complex parts . Soft tooling generally refers to less durable tools often used for prototyping or short-run production. In contrast, hard tooling is used for long-run output due to its robustness. Both have their place in the CNC cosmos, and .

Soft tooling and hard tooling each have their advantages and disadvantages, and the choice between them should align with your business’ specific needs and circumstances. If you’re not sure what’s right for your .

Soft tooling relies on creating a master pattern for a tool with flexible materials like silicone, while hard tooling relies on metal materials like Aluminum or Stainless Steel.Soft tools are often faster to produce than hard tools because soft tooling is done with materials like silicone that are easier to work with. Hard tooling, on the other hand, is done with more rigid materials like steel and aluminum and takes .

custom made metal brackets

soft tooling vs hard tools

As we've mentioned, the primary concern between hard and soft tooling -- whether you're working with sheet metal or any other material -- has to do with timeline and budget. If your timeline is condensed and your budget is . A smooth finish guarantees a seamless layup, which is critically important in hard tools. Resolving the soft tooling vs. hard tooling debate. To decide between soft tooling and hard tooling for their next project, engineers, . The Steel Supply Company uses both hard and soft tooling in our Slotted Steel Shim production. This allows a fast and cost efficient response to any shim requirement a steel fabricator requires. . Figure 7 shows small steel .Soft Tooling vs. Hard Tooling. Delineating soft tool vs. hard tool is a matter of the materials used, easily defined by the terminology. Soft tooling relies on creating a master pattern for a tool with flexible materials like silicone, while hard tooling relies on metal materials like Aluminum or Stainless Steel.

This article compares soft tool vs hard tool, helping you decide which approach is best for your needs. What is Soft Tooling? Soft tooling uses affordable materials like aluminum or 3D printed materials to create molds for injection molding. Soft tooling is used for low-volume production runs or prototyping during product development stages. Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. Follow me on: Contents. There are two broad categories of injection molding tools: . minute details and complex geometries are quicker to implement into soft tooling vs. hard tooling;

Hard tooling: Complex design at high volumes Hard tooling is what you typically think of when you picture the tool and die set that carves out intricate parts like those seen on newer cars. Hard tooling is excellent for high-volume metal parts and complex design-formed features. The result of this metal fabrication method is an accurate product component that meets your specifications . Soft Tooling vs Hard Tooling: What’s The Difference For Injection Molding? Injection molding is an exemplary manufacturing process that involves injecting material into a mold to create complex parts. Injection Molding plays a crucial role in different parts. There are two types of tooling: tooling and hard tooling. Understanding the differences between these two parts [.]

For example, silicone tooling, it may not produce more than 25 parts until they swapped out for new tools. It is hard to make change to soft tools if the tooling is completed. What is Hard Tooling? Hard tooling is a tooling method which is often sued for injection molding. Hard tools are made from durable and hard metal. Learn when to use these molding tools, and how to get help with soft tool vs hard tool selection. Trustpilot. Trustpilot. x. Try the First-Ever Auto DFM for Injection Molding Learn More. . Sheet Metal. Experience the versatility & cost efficiency with flexible application options. Injection Molding. Production-grade steel tooling, as fast as .

Soft tooling and hard tooling are used in different phases of the production process and for different types of applications. Learn more about the difference between soft tooling and hard tooling here. . Sheet Metal Fabrication. Sheet Cutting. Laser Cutting. Waterjet Cutting. Laser Tube Cutting. Tube Bending. Plastic Part Production. Plastic .Tooling vs Tools. When it comes to aviation sheet metal fabrication, tools are the jigs, fixtures, molds, dies and cutting tools used to build parts and assemblies. But tooling is the process of creating the molds, jigs and dies according to the part’s specifications.Plastic injection molding uses both soft and hard tooling; urethane casting is a different production process that also uses soft tooling. These various interpretations of the term “soft tooling” might be perplexing for product designers. Of course, adjectives like “hard” and “soft” are relative because the metal tooling used in injection molding can be classified as either hard or .

Selecting soft tooling vs. hard tooling is a critical decision that can significantly impact your product’s quality, production efficiency, and overall cost-effectiveness. Soft tooling and hard tooling each have their advantages and disadvantages, and the choice between them should align with your business’ specific needs and circumstances. Soft Tooling vs Hard Tooling: Ano ang Pagkakaiba Para sa Injection Molding? Ang paghuhulma ng iniksyon ay isang huwarang proseso ng pagmamanupaktura na kinabibilangan ng pag-iniksyon ng materyal sa isang amag upang lumikha ng mga kumplikadong bahagi. Ang Injection Molding ay gumaganap ng isang mahalagang papel sa iba't ibang bahagi. Mayroong . When Do You Use Hard Tooling vs. Soft Tooling? Since creating a silicone or fiberglass mold is far less expensive than making one out of metal, soft tooling is ideal for early production phases like prototyping or manufacturing . Sheet metal tools are used in a wide variety of manufacturing areas, from construction to automotive. And when it comes to building these parts, prototype and production tooling plays a critical role, but there’s no one-size-fits-all solution.

The different types of tooling for manufacturing boil down to soft tooling vs. hard tooling. Soft tools can be made faster and are well suited to rapid prototyping and small production runs of 1–100 units because the tools usually wear down . Soft Tooling vs Hard Tooling: Apa Bedane Kanggo Cetakan Injeksi? Cetakan injeksi minangka proses manufaktur teladan sing melu nyuntikake bahan menyang cetakan kanggo nggawe bagean sing kompleks. Molding Injeksi nduweni peran penting ing macem-macem bagean. Ana rong jinis perkakas: perkakas lan perkakas keras. Ngerteni bedane rong bagean . Soft Tooling vs Hard Tooling: Ndeupi Musiyano WeJekiseni Kuumba? Jekiseni molding inzira yemuenzaniso yekugadzira iyo inosanganisira jekiseni zvinhu muforoma kugadzira zvikamu zvakaoma. Jekiseni Molding inoita basa rakakosha muzvikamu zvakasiyana. Kune marudzi maviri ekushandisa: tooling uye hard tooling. Kunzwisisa mutsauko uripo pakati .

A major difference between the two processes is the type of tooling used to produce parts. The difference is that urethane molding produces parts from silicone (soft tooling), whereas injection molding produce parts from steel or aluminum (hard tooling). Below is a quick overview showing you the difference between the tooling methods. Resolving the soft tooling vs. hard tooling debate. To decide between soft tooling and hard tooling for their next project, engineers, designers, and parts manufacturers should consider the time they have to devote to the development and their project requirements. If speed, flexibility, and affordability are top priorities, soft tooling might .Hard tooling is a synonym for metal tooling, most often in the context of injection molding. Hard tooling can be produced with rapid tooling methods, mostly out of aluminum. Hard tooling is durable and can handle large production volumes, but incurs substantially higher costs than soft tooling or most rapid tooling methods, making it more .

Choose Right Soft Tooling and Hard Tooling Manufacturer – Be-Cu. . we offering 5 and 3 axis,Laser Cutter,3D Printer,Sheet Metal Machine,Casting Machie,EDM,Injection Molding Machine,Forging Machine,Stamping Machine capability, see prototype capabilities below. Volume: 1-1000K+ Parts .Soft Tooling. Soft tooling is made from materials such as aluminum, copper, brass, and other metals. These materials are machined into the desired shape of the part. The process of creating a soft tool is faster and less expensive than hard tooling, making it a desirable option for prototyping and low-volume production.An injection mold is a customized machine tool that is used in the production of injection molding products.It is used to mold molten pieces of plastics together to form molding products.For those who provide plastic injection molding service, injection mold is indispensable.. In this article, we would briefly discuss the different (soft and hard) tooling methods. Soft Tooling vs Hard Tooling: Unsa ang Kalainan Alang sa Injection Molding? Ang paghulma sa pag-injection usa ka ehemplo nga proseso sa paggama nga naglakip sa pag-inject sa materyal ngadto sa usa ka agup-op aron makahimo mga komplikado nga mga bahin. Ang Injection Molding adunay hinungdanon nga papel sa lainlaing mga bahin. Adunay duha ka .

custom metal fabrication alabama

Hard tooling is a synonym for metal tooling, most often in the context of injection molding. Hard tooling can be produced with rapid tooling methods, mostly out of aluminum. Hard tooling is durable and can handle large production volumes, but incurs substantially higher costs than soft tooling or most rapid tooling methods, making it more .

soft tooling injection molding

custom marine aluminum fabrication

soft tolling

Find your future faster and see if a degree in metal fabricator is right for you. Explore metal fabricator degree programs, pay data for in-demand metal fabricator careers and the best metal fabricator schools.

sheet metal soft tooling vs hard tooling|hard tooling vs hard tools