add layer of sheetrock electrical box Translating this to typical materials available at home Depot. You may find putting a couple of insulation layers between the drywall layers very effective. Say buy some of that bubble wrap .

They support Mazak CNC’s of any age with service and parts with factory-trained .

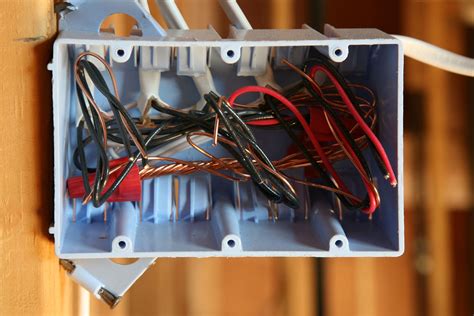

0 · plastic electrical box installation

1 · installing electrical boxes on drywall

2 · installing electrical box in plaster

3 · installing electrical box in finished wall

4 · how to install electrical boxes

5 · electrical boxes for walls

6 · electrical box installation instructions

7 · diy electrical box installation

Section 331 (a) of the IRS tax code says that if a shareholder is eligible to receive a cash liquidation distribution totaling $600 or more, the distribution must be reported on Form.

plastic electrical box installation

If you are using clips and channel with two layers of 5/8 DW I add one inch furring to the front of the stud. With clips and channel the leading . 2 layers of sheet rock could be a 2 hr wall assembly - need proper protection for a 1 hr box, cannot use plastic cut in in a rated wall only metal. you may have to mount the box to a .

Then, in the center of where your device screw would go (sheetrock) tap in your flathead screwdriver which will slightly separate the layers of rock. Slip the backbone of the .

metal box corner home depot

Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Not all fixtures need to be attached to a wall stud or joist. . After the clips, hat track, and two layers of drywall, we're talking about an added distance from the electrical boxes of over 3 inches. Quick research has lead me to electrical .Translating this to typical materials available at home Depot. You may find putting a couple of insulation layers between the drywall layers very effective. Say buy some of that bubble wrap . Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and .

1) Add wire in the box, try to find long enough box extender. (2 1/2″. Any suggestions as to where I can find such an animal?) 2) Add some wire, close up the existing . I understand the ease of cutting out around an electrical box with the sheet of drywall in place. No guess work, just locate the center of the box and then find the edges from .

Best bet would probably be to use a metal box with Madison bars to secure it. I would suggest that you use something like this box extender or you can go the difficult route and install deep . If you are using clips and channel with two layers of 5/8 DW I add one inch furring to the front of the stud. With clips and channel the leading edge needs to be around 2 1/2 inches in front of the stud face. +/- depending on choice of clip.

2 layers of sheet rock could be a 2 hr wall assembly - need proper protection for a 1 hr box, cannot use plastic cut in in a rated wall only metal. you may have to mount the box to a stud & have a putty pad for protection. Then, in the center of where your device screw would go (sheetrock) tap in your flathead screwdriver which will slightly separate the layers of rock. Slip the backbone of the madison into this gap. Then slide the madison into place. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Not all fixtures need to be attached to a wall stud or joist. Lightweight fixtures can hold up on plaster or drywall if you have a remodel electrical box. After the clips, hat track, and two layers of drywall, we're talking about an added distance from the electrical boxes of over 3 inches. Quick research has lead me to electrical box extenders, but they only work for so many inches, so I will need to find another way to accommodate that distance.

Translating this to typical materials available at home Depot. You may find putting a couple of insulation layers between the drywall layers very effective. Say buy some of that bubble wrap type stuff and then a 1/2 layer of urethane or styrofoam foam . Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are large enough for the wires they hold.

1) Add wire in the box, try to find long enough box extender. (2 1/2″. Any suggestions as to where I can find such an animal?) 2) Add some wire, close up the existing box and run the new wire to a “new work box” mounted on the new wall.

I understand the ease of cutting out around an electrical box with the sheet of drywall in place. No guess work, just locate the center of the box and then find the edges from there. The process seems like it would be even easier if one had a .

Best bet would probably be to use a metal box with Madison bars to secure it. I would suggest that you use something like this box extender or you can go the difficult route and install deep retrofit boxes post drywall. Pick your poison, but I’d go with option #1 if were me. If you are using clips and channel with two layers of 5/8 DW I add one inch furring to the front of the stud. With clips and channel the leading edge needs to be around 2 1/2 inches in front of the stud face. +/- depending on choice of clip. 2 layers of sheet rock could be a 2 hr wall assembly - need proper protection for a 1 hr box, cannot use plastic cut in in a rated wall only metal. you may have to mount the box to a stud & have a putty pad for protection. Then, in the center of where your device screw would go (sheetrock) tap in your flathead screwdriver which will slightly separate the layers of rock. Slip the backbone of the madison into this gap. Then slide the madison into place.

Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Not all fixtures need to be attached to a wall stud or joist. Lightweight fixtures can hold up on plaster or drywall if you have a remodel electrical box. After the clips, hat track, and two layers of drywall, we're talking about an added distance from the electrical boxes of over 3 inches. Quick research has lead me to electrical box extenders, but they only work for so many inches, so I will need to find another way to accommodate that distance. Translating this to typical materials available at home Depot. You may find putting a couple of insulation layers between the drywall layers very effective. Say buy some of that bubble wrap type stuff and then a 1/2 layer of urethane or styrofoam foam .

Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are large enough for the wires they hold. 1) Add wire in the box, try to find long enough box extender. (2 1/2″. Any suggestions as to where I can find such an animal?) 2) Add some wire, close up the existing box and run the new wire to a “new work box” mounted on the new wall.

I understand the ease of cutting out around an electrical box with the sheet of drywall in place. No guess work, just locate the center of the box and then find the edges from there. The process seems like it would be even easier if one had a .

metal box company westhoughton

$10.48

add layer of sheetrock electrical box|installing electrical box in finished wall