double seam sheet metal This 180-degree mechanically seamed panel is designed for sheet metal siding, roofing and fascia applications, bringing versatility and reliability to both open framing and solid sheathing . Check out our wooden electric box cover selection for the very best in unique or custom, handmade pieces from our wall hangings shops.

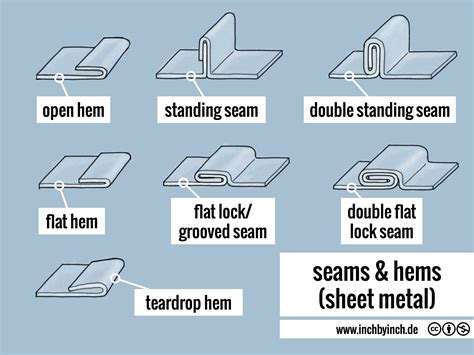

0 · types of sheet metal seams

1 · sheet metal side seam

2 · sheet metal seams pdf

3 · sheet metal seams explained

4 · sheet metal seams diagram

5 · sheet metal seam sizes

6 · sheet metal seam joints

7 · sheet metal duct seam

VINTAGE 1978 INCREDIBLE HULK METAL LUNCHBOX W/ THERMOS Description For auction is a used 1978 Incredible Hulk Metal lunchbox with thermos, made by Aladdin , couple little dents and rust

The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a .

Learn how sheet metal seams are made and used in the HVAC industry to fabricate air conditioning ductwork.

This 180-degree mechanically seamed panel is designed for sheet metal siding, roofing and fascia applications, bringing versatility and reliability to both open framing and solid sheathing .Elevate UNA-CLAD UC-3 Roofing Panel is a factory formed double-lock, architectural standing seam metal roof panel that provides a traditional look and utilizes mechanical seaming to .PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural roofing panel aesthetics. PAC-150 roofing coil for field-forming operations is leveled to provide superior panel flatness.

The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a HAND GROOVER (fig. 2-58).Constructed with two open seams like a grooved seam, the double seam has a 90-degree angle to form a corner. This joint is ideal for compound curves and may require special tooling to clasp it tightly. Learn how sheet metal seams are made and used in the HVAC industry to fabricate air conditioning ductwork.This 180-degree mechanically seamed panel is designed for sheet metal siding, roofing and fascia applications, bringing versatility and reliability to both open framing and solid sheathing installations.

types of sheet metal seams

Elevate UNA-CLAD UC-3 Roofing Panel is a factory formed double-lock, architectural standing seam metal roof panel that provides a traditional look and utilizes mechanical seaming to enhance design needs. With its proven high wind performance capabilities, UC-3 Roofing Panel can be curved and tapered to accommodate complex architectural geometry.PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural roofing panel aesthetics. PAC-150 roofing coil for field-forming operations is leveled to provide superior panel flatness.“Roll Former SSX” power seamer is design for 1” or 1-1/2” B1301/1300 panels and will form a complete 180 degrees; double lock standing seam with a single pass. The nose switch cuts the unit off if it comes to the edge of the roof, elimating expensive and time consuming accidents.

sheet metal side seam

This double seam reference chart is intended for use by personnel responsible for setting and checking double seams. In addition, the chart will provide a useful guide to good double seaming practice, for engineers, production operators and quality assurance personnel.Butler’s MR-24 ® conventional roof system is the industry’s #1 standing-seam metal roof system. It’s engineered for performance and proven to deliver superior protection and efficiency.

A seam joint is created by folding and joining the edges of two metal sheets to form a seam. The seam can be folded in various ways, like single seams or double seams, depending on the specific requirements.The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a HAND GROOVER (fig. 2-58).

Constructed with two open seams like a grooved seam, the double seam has a 90-degree angle to form a corner. This joint is ideal for compound curves and may require special tooling to clasp it tightly. Learn how sheet metal seams are made and used in the HVAC industry to fabricate air conditioning ductwork.This 180-degree mechanically seamed panel is designed for sheet metal siding, roofing and fascia applications, bringing versatility and reliability to both open framing and solid sheathing installations.

Elevate UNA-CLAD UC-3 Roofing Panel is a factory formed double-lock, architectural standing seam metal roof panel that provides a traditional look and utilizes mechanical seaming to enhance design needs. With its proven high wind performance capabilities, UC-3 Roofing Panel can be curved and tapered to accommodate complex architectural geometry.PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural roofing panel aesthetics. PAC-150 roofing coil for field-forming operations is leveled to provide superior panel flatness.“Roll Former SSX” power seamer is design for 1” or 1-1/2” B1301/1300 panels and will form a complete 180 degrees; double lock standing seam with a single pass. The nose switch cuts the unit off if it comes to the edge of the roof, elimating expensive and time consuming accidents.

This double seam reference chart is intended for use by personnel responsible for setting and checking double seams. In addition, the chart will provide a useful guide to good double seaming practice, for engineers, production operators and quality assurance personnel.Butler’s MR-24 ® conventional roof system is the industry’s #1 standing-seam metal roof system. It’s engineered for performance and proven to deliver superior protection and efficiency.

real steel world robot boxing cheats ios

sheet metal seams pdf

We manufacturer CNC woodworking machines built in the USA with all-steel frames that come fully assembled and pre-tested. We provide the industry’s best customer service and training.

double seam sheet metal|sheet metal seams explained