metal fabrication safety checklist Fabrication - Checklist - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. The company has 10 years of experience manufacturing material handling structures and equipment. It has . Junction boxes are used in most of the electrical and instrumentation installations. A junction box in the instrumentation field is a device that would act as an interconnecting medium between the process field instruments and the equipment which is used to control and monitor the field instruments, this equipment would be located in the .

0 · sheet metal fabrication safety

1 · safety of metal fabrication

2 · metal fabrication safety standards

3 · metal fabrication safety requirements

4 · metal fabrication safety hazards

5 · metal fabrication safety clothing

6 · mechanical fabrication shop safety manual

7 · fabrication shop safety topics

Sheet metal is created in just five stages: melting, pouring, pickling, oxidisation and rust protection and rolling and annealing. As we know – sheet metal can be made from several different types of metal such as aluminium, stainless steel .

Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal.Any time injuries occur frequently and repetitively it’s worth a closer look. Following are the most common injures in mechanical industry fabrication shops, and safe work practices to help you .Fabrication Inspection and Testing of Structural Metal Products 11-1-1 Topic No.: 675-000-000 Materials Manual Effective: August 19, 2004 Steel and Miscellaneous Metal Products CHAPTER 11.1 FABRICATION INSPECTION AND TESTING OF STRUCTURAL METAL PRODUCTS. 11.1.1 PURPOSE This procedure provides guidance for the development and implementation ofFabrication - Checklist - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. The company has 10 years of experience manufacturing material handling structures and equipment. It has .

The 1st event is a Fabrication Workshop, where sheet metal fabricators gather to share techniques and innovations in metalworking. The 2nd event is a Safety Training Seminar, focusing on best practices and new safety protocols to ensure a secure working environment.%PDF-1.5 %âãÏÓ 533 0 obj > endobj 557 0 obj >/Filter/FlateDecode/ID[6101BDA915E51344AD07A1CD809BAE8D>]/Index[533 50]/Info 532 0 R/Length 113/Prev 191518/Root 534 .SAFETY AND HEALTH LAW FOR MANY OF THE TOPICS COVERED IN THESE CHECKLISTS. When you have completed the checklists, you will have enough information to decide if problems exist. Once you have identified hazards, you can begin corrective actions and control procedures. SCOPE. The scope of self-inspections should cover the following areas:GENERAL SAFETY YES NO N/A COMMENTS Administrative responsibility for shop safety has been clearly defined. Machine users have completed “Basic Machine Shop Safety” and specific training on individual tools and training is documented. Where necessary, lock-out/tag-out procedures are documented for each piece of equipment, and training

Toolbox Safety Talks for Fabrication Shops Mechanical Contractors Association of America, Inc. 1385 Piccard Drive Rockville, MD 20850 800-556-3653 • www.mcaa.org . Title: Toolbox Safety Talks for Fabrication Shops Author: MCAA Subject: .Metal Fabrication Cutting Checklist: A detailed checklist to assist metal workers in the cutting phase of their fabrication projects. 4. Metal Cutting Safety Checklist: A safety-focused checklist for metal workers to follow during the cutting process, ensuring a secure working environment. 5. Efficient Metal Cutting Checklist: A checklist .

sheet metal fabrication safety

A safety-first operation will also make OSHA compliance front and center in their quality control program. 5: Implementing a Safety-Savvy Quality Control Program for OSHA-Compliant Fabrication. Experienced metal fabricators make safety best practices an integral part of their documented quality control (QC) program. As part of the QC program at .The Safety Checklist for Metal Punch Press Operator is used before operating a metal punch press machine to ensure the safety of the operator and prevent any potential accidents or injuries. This checklist is particularly important in industries where metal fabrication and manufacturing processes are involved.Home Delivery Safety Checklist. . McShane has made over 200,000+ metal box solutions in almost every industry imaginable. Use our expertise and knowledge to help secure your home deliveries in the ever-expanding world of porch theft. . McShane Metal Products, Welding & Fabrication. 12 Port Access Road Erie, PA 16507 . Phone: 1 (800) 735 .Confirm project specifications Confirm the specifications of the project with the client to ensure clear understanding of the requirements. This task plays a crucial role as any miscommunication can lead to errors in the fabrication process. The desired result is to have accurate project specifications for the steel fabrication process. Do you have the project

Let us take a look at a basic inspection checklist for structural steel fabricators. Safety Measures. The first and foremost thing to ensure is the safety measures that are necessary to take for fabricators. Fabrication is a complex process which .The Manufacturing industry is a priority industry for work health and safety. The structural metal product manufacturing industry has one of the highest incidence rates of serious . either unaware of formal checklists and procedures or questioned their relevance to small

Get everything you need for safety in one place - Metal Fabrication Shop Safety Program with plans, manuals, and checklists. Get instant access today! LOGIN. SERVICES Close SERVICES Open SERVICES. . – Jobsite and Workplace Inspection Checklists & Forms – .of welding fabrication safety related to the areas of light metal. You must read, learn, and follow all safety rules, regulations, and procedures for those areas. Light welding fabrication, like all other areas of welding work, has a number of potential safety hazards. These hazards need not result in anyone being injured.Among our metal fabrication equipment, you can find plasma cutting systems, hydraulic press brakes, fiber lasers, tube cutting machines, metal folders, cut-to-length, deburring and finishing machines, and more. While we have top-of-the .

1.0 THEORY The term ‘sheet metal’ is used to mean metal having thickness in the range from 0.4mm to 6 mm. When the thickness is more than 6 mm, the metal is called a plate. Products made from sheet metal can be found almost anywhere. Metal tables, steel cabinets, car bodies, beverages cans and home appliances are some of the common examples. The .Update the quality control checklist based on the latest findings from inspections and tests. This task is important in ensuring that the checklist remains up-to-date and reflects any changes or improvements in the quality control process. The desired result is an updated checklist that incorporates the most recent knowledge and lessons learned.When you’re ready to start planning, get in touch to request a custom event planning checklist template. The 1st event is a Welding Workshop, where metal fabricators gather to enhance their skills and learn new techniques. The 2nd event is a Safety Training Seminar, focusing on the latest safety protocols and equipment handling practices.

The Welding Checklist for Sheetmetal Fabricator is used during the welding process in sheetmetal fabrication. This checklist ensures that all necessary steps and precautions are taken to achieve high-quality welds. It is used by sheetmetal fabricators to ensure that they follow proper welding procedures and adhere to safety guidelines. Metal fabrication is an integral part of many different industries, and it can be one of the most dangerous due to the tools and techniques necessary to complete each task. Metal shop injuries are often extreme and can be even fatal in some situations. Why is metal fabrication safety so important? What can shop owners and supervisors do to ensure their factory floors .

safety of metal fabrication

8 WORKSAFE VICTORIA / A GUIDE TO SAFETY IN THE METAL FABRICATION INDUSTRY MANUAL HANDLING UNLOADING RAW MATERIALS When unloading raw materials, incidents have occurred where people use levers, such as metal bars to manually lever steel and other metal products off delivery vehicles. This practice is known as ‘barring off’. By using purpose .

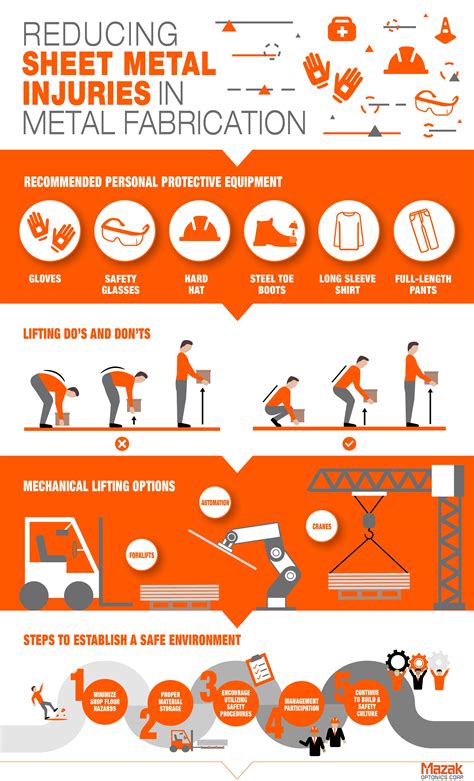

First, let’s cover the most common safety concerns within the metal fabrication industry, their costs, and an umbrella method of solutions. 1. Machine Guarding. According to OSHA reports, guarding and the proper usage of machinery cost the metal fabrication industry nearly million. Moving machinery creates the potential for crushed fingers .

The examples outlined below do not list all the possible items for manufacturing facilities. The best checklist for your workplace is one that has been developed for your specific needs. Whatever the format of the checklist, provide . The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970. start your free subscriptionMaking Room for AI in the Fabrication Space--While Prioritizing Safety. How can a company best determine where AI fits into its workflow? It helps to have an AI advocate. Take Drake-Williams Steel in Omaha, for example, whose safety manager, Ben Thornburg, is actively looking for ways to productively implement AI in his company’s fab shop. .

metal fabrication safety standards

metal fabrication safety requirements

Heavy fabrication is a complex discipline that requires the careful coordination of many teams to machine, mold, assemble, coat, and deliver large steel applications. These heavy fabrications include pressure vessels, .

metal fabrication safety checklist|metal fabrication safety standards