how to make a cnc machine from printer parts I used the 3D printer to make bearing mounts, smoothrod mounts, Z axis gantry parts and some cosmetic parts. With careful planning and design, I was able . Metal Fabricated To Your Needs . 1925 N.Lancater-Hutchins Rd. Lancaster,TX 75134. ph 972-227-0200 fax 972-227-0207Wilson Metal Fabricators, Inc. 1925 N. Lancaster-Hutchins Rd Lancaster, TX 75134 United States ph: 972-227-0200 fax: 972-227-0207 wilsonme

0 · simple cnc machine with minimum parts

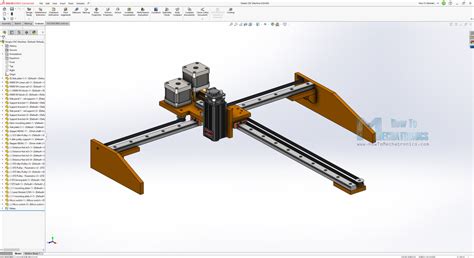

1 · simple cnc machine

2 · mechatronics cnc machine

3 · diy cnc machine

4 · diy cnc engraving machine

5 · cnc laser engraving machine

6 · cnc laser engraver circuit diagram

7 · 3d printer cnc machine

Consolidates your truck's electrical wiring. Electrical Junction Boxes from Buyers Products provide an organized way to terminate and consolidate your electrical wiring. Choose from a polypropylene boxes with plain terminals or an ABS plastic box .

Bipolar stepper motor controller_Home Madehttps://youtu.be/OsMilSlpCkwprinter shape rodprinter timing beltprinter head timing pulley printer head socket 1/2 .

metallic green flies my house

Home Made CNC Reuses Printer Parts. Do it yourself CNC machines can be never ending projects. Once you get one machine done, you .One such example is converting an old printer into a CNC (Computer Numerical Control) machine. In this article, we will explore the step-by-step process of transforming an old printer .I used the 3D printer to make bearing mounts, smoothrod mounts, Z axis gantry parts and some cosmetic parts. With careful planning and design, I was able .

Install Raid for Free IOS/ANDROID/PC: https://clcr.me/nsSoGZ and get a special starter pack 💥 Available only for the next 30 daysCode, 3D model, parts lis.Simple CNC From Scrap Printers: After building my 3D printer out of old printers and MDF and using it for a few years, I want to expand my machine shop with a CNC machine. Before to go and buy expensive aluminium extrusions and . Follow Razihel:http://www.facebook.com/RazihelOfficialhttp://www.soundcloud.com/Razihelhttp://www.youtube.com/razihelOfficialhttp://www.twitter.com/razihelof.

JLCPCB Prototype for (Any Color): https://jlcpcb.comHello Guys, in this tutorial I am going to show you how to make a DIY CNC Machine without Arduino Codin.

Facebook : https://www.facebook.com/MechatronicslkpagePart List :Arduino UnoL293D Motor Driver ShieldServo Motor 9GDVD Rom or Writer [x2]Code & .

DIY Homework Writing Machine: In this Instructable, I'll show you how to create a completely functional 3D-printed writing machine for your science fair project at school or college. This project was created as part of my second-year .

With smaller parts, it can often be faster to 3D print than to machine. With a CNC machine you have to spend time getting stock, writing G-code, figuring out work holding, setting up tools, and cleaning up after. Some parts can print in the time it takes just to get a CNC machine ready. Open source large format CNC-machine & 3d-Printer For a schoolproject we decided to build this CNC-machine. For those, wanting to view the . In the Github-Repo you can find the Documentation and CAD files for a large format CNC-machine we build with OpenBuilds parts. The total size of the machine is roughly: X: 172 cm; Y: 172 cm; Z: 128 cm .In this instructable I will show you how to make a very low cost CNC from recycled computer parts. This machine can do a lot of stuff depending on what you attach to it. 1. It can be used as a Plotter. (Attach a Pen as tool) 2. It can be a Laser Engraver. (Attach a Laser module as tool). 3. It can be used as a Router. (Attach a Drill Machine as .

The drawer slides have too much lateral tolerance for a precision table, but are fine for making a lot of parts that don't require +/-0.005 We can make both the precision table parts for the CNC table as well as the 3D Printer table parts with a quick and simple table.The Arduino CNC Drawing Machine | 2d Plotter | How to Make Arduino 2d Plotter Cnc Machine: Hi guys, so this instructable will help you out to make simple, less budget Arduino cnc plotter. In this project i had used some recycled parts like printer rail, smps box cd drive mechanism etc.. so the supplies that you should buy are less and le.

Cautions. Whether you are building an affordable CNC router, or making the best budget CNC lathe machine, even working with DIY the cheapest CNC milling machine, the first caution is the power supply of the CNC machine.There are three stepping motors and one spindle motor on the machine. Therefore, the current of the CNC machine is very large in the process . Follow Razihel:http://www.facebook.com/RazihelOfficialhttp://www.soundcloud.com/Razihelhttp://www.youtube.com/razihelOfficialhttp://www.twitter.com/razihelof. Furthermore, Arduino can control various CNC machines, ranging from 3D printers to laser cutters. That said, Arduino is the best controller if you want to build a CNC machine. Let's now get started on how to build a simple CNC machine using Arduino. What You Will Need. To create a CNC machine with Arduino, you will need:-An Arduino microcontrollerInstall Raid for Free IOS/ANDROID/PC: https://clcr.me/nsSoGZ and get a special starter pack 💥 Available only for the next 30 daysCode, 3D model, parts lis.

The circuit diagram used in this project is shown here, start by connecting the motor drivers to the CNC shield. Followed by connecting the enabling pins together, Now connect the stepper motors to the CNC shield, The laser diode has to be connected to the power supply via IRFZ44N Mosfet and a couple of resistors.

CNC machines can make furniture that ranges from simple shelves and desks, to chairs and tables. . And it’s not uncommon for those who regularly work on making CNC projects to have a lot of spare parts, tools and materials lying around. . Snapmaker 3-in-1 CNC projects (And 3D printing and laser cutting) Glowforge projects;

simple cnc machine with minimum parts

A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . Just finished my re print of my first CNC using all leftover 3D printer parts (minus the GRBL shield) from my numerous printers over the ./r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. Members Online • Harsh182 . But it doesn't make 3d printers less of a CNC machine. Reply replyTurn an Old 3D Printer Into a CNC Machine: Turn an old 3D printer into a CNC machine Well yes.But there are issues. I made a video sponsored by Banggood who have given me a 0 CNC spindle and some tooling to try .

Making money with a CNC machine can be a lucrative business opportunity. CNC machines are used for precision machining tasks in various industries, including manufacturing, woodworking, and metalworking. . CNC machines can be used to cut, shape, and engrave metal parts and products. Offer your services to businesses that require custom metal . 4pcs A4988 Stepper motor driver connect on expansion board A4988 driver module, then connect the arduino with expansion board and connect all wiring The shield also has a built-in micro stepping control - meaning that instead of using full steps or half steps like a large CNC would do, we can make the motors move by 1/16 or 1/32 of a step to . CNC machines come in various forms to accommodate the diverse needs of the manufacturing industry. CNC Lathe Machines. These machines are the modern-day equivalent of traditional lathes. They rotate the workpiece against a cutting tool to shape it into symmetrical objects, such as cones and cylinders. . Metal 3D Printing: Metal 3D printing is .To make a CNC machine from scratch or modify and existing one. If you know where there is an old router, or bench, or you already have one, no matter the size, it is quite simple to make it in to a CNC machine, think about it, all the stuff is already there, it just needs some motors to run the axes and you are good to hook up the rest.

Most people use the parts found in printers to make their own CNC Machines and 3D Printers. Step 3: Some of the Useful Parts From an Old Inkjet Printer. The most sough after parts in printers are the stepper motors (usually from laser printers), regular DC motors, steel rods and shafts, a whole bunch of gears and gearing systems, screws .

How to Make a Cnc Machine. Building a Cnc Machine at Home Start to FinishBest friends,in this video I will show you how I made a homemade cnc machine, of cou. It is not advisable that you try to convert a CNC machine to a 3D printer, although you could use the parts of a CNC machine to replace some parts of a 3D printer. The CNC machine is usually bigger in size as compared to the 3D printer, so the Z-axis is very large.

3D printing has come a long way from where it first started out. Today, this billion-dollar industry has become as multi-faceted as ever, having numerous applications that range from car parts to jewelry-making and a lot more. This technology also plays a large role in making purpose-oriented prints having mechanical properties. The possibilities are just. use EASEL (an online platform to make 2D shapes) download files from EASEL and open them with EASEL; connect your machine to the computer with a USB cable; zero out your machine and get ready for the test

People assume you can make anything on a CNC but there's still many limitations. The design you want looks cool but is not practical to manufacture. Sure, its technically possible but would cost a fortune to produce. If you had a quarter million dollar five-axis machine, 5 to 10 years experience, and unlimited time- then it might be possible

simple cnc machine

Convertible Stainless Steel Under Cabinet Range Hood with Mesh filters and Charcoal Filters and Push Button Control. Can vent through top or back, Vent location on the .

how to make a cnc machine from printer parts|cnc laser engraving machine