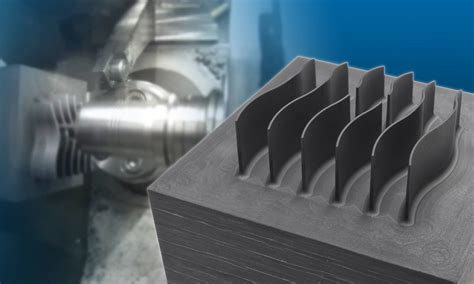

cnc graphite machining Machining Graphite with CNC Machines. CNC machining is an effective way of machining graphite because it allows for highly precise and complex shapes to be created with .

Purpose and Function of a Junction Box . The junction box serves as the communal meeting spot for electrical wires, where they connect before .

0 · machining graphite feeds and speeds

1 · how to grind graphite

2 · graphite machining near me

3 · graphite machining companies

4 · graphite machine shop

5 · graphite electrode machining

6 · graphite cutting speed chart

7 · graphite blocks for machining

The reason for the two spacings is the two sizes of steel octagon box (pictured). The older, now largely obsolete 3-1/2" trade size (3-1/2" across corners, 3" across flats) had 2-3/4" screw spacing. The current 4" trade size (4" across corners, 3 .Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Learn five essential graphite machining tips with Semco Carbon's expert guide including dry machining, sharp tooling, and effective dust managementTake a look to see how a graphite machining center can work for you. A compact vertical machining center precision-designed to make high-accuracy graphite electrodes to then create .

CNC machined graphite components are used extensively as electrodes in electrical discharge machining. Graphite's electrical conductivity, machinability, and low wear rate make it an ideal choice for this precision .

Absolute Machine Tools offers solutions for manufacturers machining graphite and burning electrodes, including the Tongtai TMV-510G and Accutex Die Sinkers. The TMV-510G is . Graphite presents machinists and CNC operators with some unique challenges. Graphite is a softer material than steel and has some of the same characteristics as Aluminum for machining and fabricating.

Machining Graphite with CNC Machines. CNC machining is an effective way of machining graphite because it allows for highly precise and complex shapes to be created with .Consistent dimensional size from part to part and reduced operator involvements are all benefits of CNC machine tools. Due of the abrasive characteristics of graphite, it was customary to use .

machining graphite feeds and speeds

When it comes to graphite machining, CNC machines bring several advantages, including enhanced material removal rates, improved surface finishes, and reduced tool wear. This .

From 5-axis CNC milling and the largest diameter machining in the market to sawing, sanding, and grinding capabilities we set the standard for versatility in the graphite-machining world. Graphite has as many applications in industry as it . In this post, we will examine graphite’s material properties, key CNC machining techniques, and tips for properly selecting cutting tools for graphite.

Learn five essential graphite machining tips with Semco Carbon's expert guide including dry machining, sharp tooling, and effective dust management

Take a look to see how a graphite machining center can work for you. A compact vertical machining center precision-designed to make high-accuracy graphite electrodes to then create .

how to grind graphite

CNC machined graphite components are used extensively as electrodes in electrical discharge machining. Graphite's electrical conductivity, machinability, and low wear rate make it an ideal choice for this precision manufacturing technique.

Absolute Machine Tools offers solutions for manufacturers machining graphite and burning electrodes, including the Tongtai TMV-510G and Accutex Die Sinkers. The TMV-510G is engineered for efficient production of precision graphite electrodes and similar items. Graphite presents machinists and CNC operators with some unique challenges. Graphite is a softer material than steel and has some of the same characteristics as Aluminum for machining and fabricating.

Machining Graphite with CNC Machines. CNC machining is an effective way of machining graphite because it allows for highly precise and complex shapes to be created with accuracy. Graphite is a brittle and soft material that can be difficult to work with using traditional machining methods.Consistent dimensional size from part to part and reduced operator involvements are all benefits of CNC machine tools. Due of the abrasive characteristics of graphite, it was customary to use high-grade, TiN coated carbide inserted tools.

When it comes to graphite machining, CNC machines bring several advantages, including enhanced material removal rates, improved surface finishes, and reduced tool wear. This section will delve into the specific features and functionalities of CNC .From 5-axis CNC milling and the largest diameter machining in the market to sawing, sanding, and grinding capabilities we set the standard for versatility in the graphite-machining world. Graphite has as many applications in industry as it does grades, properties, and specifications.

In this post, we will examine graphite’s material properties, key CNC machining techniques, and tips for properly selecting cutting tools for graphite.Learn five essential graphite machining tips with Semco Carbon's expert guide including dry machining, sharp tooling, and effective dust managementTake a look to see how a graphite machining center can work for you. A compact vertical machining center precision-designed to make high-accuracy graphite electrodes to then create . CNC machined graphite components are used extensively as electrodes in electrical discharge machining. Graphite's electrical conductivity, machinability, and low wear rate make it an ideal choice for this precision manufacturing technique.

graphite machining near me

Absolute Machine Tools offers solutions for manufacturers machining graphite and burning electrodes, including the Tongtai TMV-510G and Accutex Die Sinkers. The TMV-510G is engineered for efficient production of precision graphite electrodes and similar items. Graphite presents machinists and CNC operators with some unique challenges. Graphite is a softer material than steel and has some of the same characteristics as Aluminum for machining and fabricating.

Machining Graphite with CNC Machines. CNC machining is an effective way of machining graphite because it allows for highly precise and complex shapes to be created with accuracy. Graphite is a brittle and soft material that can be difficult to work with using traditional machining methods.Consistent dimensional size from part to part and reduced operator involvements are all benefits of CNC machine tools. Due of the abrasive characteristics of graphite, it was customary to use high-grade, TiN coated carbide inserted tools.When it comes to graphite machining, CNC machines bring several advantages, including enhanced material removal rates, improved surface finishes, and reduced tool wear. This section will delve into the specific features and functionalities of CNC .

house number metal sign hanging

house metal

Discover the different types of music boxes available, from the traditional Reuge to the retro Jukebox. Learn about their history, features, and value. Skip to contentAn ammunition box or cartridge box is a container designed for safe transport and storage of ammunition. It is typically made of metal, wood, and corrugated fiberboard, etc. Boxes are labelled with caliber, quantity, and manufacturing date, lot number, UN dangerous goods labels. With a metal container, rubber gasket is commonly found in the hinged lid to pr.

cnc graphite machining|how to grind graphite