cutting curves in sheet metal In this video Joe goes over the Eastwood throatless shear, the BEST way to slice through sheet metal while making intricate cuts! MORE INFO: https://www.east. This vintage black dome metal coal miners lunch box is a unique pre-1970s collectible with charming modifications. Well-loved and well-used, its condition adds to its authentic appeal in the coal mining niche.

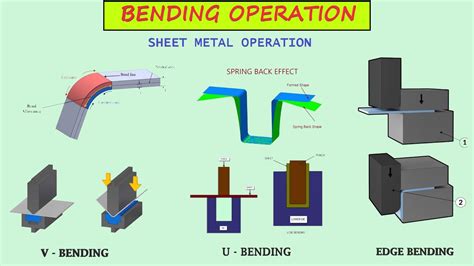

0 · types of sheet metal bending

1 · sheet metal curved flange

2 · flanging tool for sheet metal

3 · cutting and bending sheet metal

4 · bending sheet metal by hand

5 · bending sheet metal at home

6 · bending sheet metal 90 degrees

7 · bending 18 gauge sheet metal

At Victoria Sheet Metals, we design, manufacture and install bespoke .

types of sheet metal bending

clamping metal snaps fabric

sheet metal curved flange

In this video Joe goes over the Eastwood throatless shear, the BEST way to slice through sheet metal while making intricate cuts! MORE INFO: https://www.east.How to cut sheet metal complex shapes and curves with ease. Sheet metal fabrication is a complex canvas about more than rigid angles and straight lines. Curves, spirals, and intricate patterns can bring a design alive. While stunning, . The best way to cut intricate designs in sheet metal is to make a stencil for the design and trace it onto the metal. A hole punch can also help you begin to cut out sections .

What Is the Best Way to Cut Sheet Metal? If you are cutting either straight lines or curves, you don’t have power tools, and you don’t have much sheet metal to cut, your best option is to use a pair of tin snips. Place the sheet metal on top of the workbench and lay out your pattern using a tape measure, pencil, and straightedge. If your project requires curved cuts, make an easy, economical, and. Discover practical tips & tricks for cutting sheet metal with precision like a professional. Learn how to master the cut.

Aviation snips, also called tin snips or compound snips (even though they are different), are the best hand tools for cutting sheets of metal. Cutting in a straight line with tin snips is.In this posting we will take a look at some of the most common types of sheet metal cutting. When determining which method of sheet metal cutting is right for you you should take into consideration the factors of flexibility, speed, .

clamshell junction box

In this video Joe goes over the Eastwood throatless shear, the BEST way to slice through sheet metal while making intricate cuts! MORE INFO: https://www.east.How to cut sheet metal complex shapes and curves with ease. Sheet metal fabrication is a complex canvas about more than rigid angles and straight lines. Curves, spirals, and intricate patterns can bring a design alive. While stunning, these complex shapes present their challenges.To compensate for how metal may curve or bend, cut a strip out where you use red snips for one side and green snips on the other, cutting 2 inches at a time on alternating sides – so, two inches up the right side, two inches up the left. This controls how the metal flexes and gets a cleaner cut. That’s because many sheet metal cutting jobs call for curves. For that purpose, you’d need a set of left- and right-cutting tin snips. Luckily, these snips and their straight-cutting counterparts often come in a set.

The best way to cut intricate designs in sheet metal is to make a stencil for the design and trace it onto the metal. A hole punch can also help you begin to cut out sections more easily. Sharp, precise, quality tools are important. What Is the Best Way to Cut Sheet Metal? If you are cutting either straight lines or curves, you don’t have power tools, and you don’t have much sheet metal to cut, your best option is to use a pair of tin snips. Place the sheet metal on top of the workbench and lay out your pattern using a tape measure, pencil, and straightedge. If your project requires curved cuts, make an easy, economical, and.

Discover practical tips & tricks for cutting sheet metal with precision like a professional. Learn how to master the cut.

Aviation snips, also called tin snips or compound snips (even though they are different), are the best hand tools for cutting sheets of metal. Cutting in a straight line with tin snips is.

In this posting we will take a look at some of the most common types of sheet metal cutting. When determining which method of sheet metal cutting is right for you you should take into consideration the factors of flexibility, speed, accuracy, finish, cost and automation.

In this video Joe goes over the Eastwood throatless shear, the BEST way to slice through sheet metal while making intricate cuts! MORE INFO: https://www.east.

How to cut sheet metal complex shapes and curves with ease. Sheet metal fabrication is a complex canvas about more than rigid angles and straight lines. Curves, spirals, and intricate patterns can bring a design alive. While stunning, these complex shapes present their challenges.To compensate for how metal may curve or bend, cut a strip out where you use red snips for one side and green snips on the other, cutting 2 inches at a time on alternating sides – so, two inches up the right side, two inches up the left. This controls how the metal flexes and gets a cleaner cut. That’s because many sheet metal cutting jobs call for curves. For that purpose, you’d need a set of left- and right-cutting tin snips. Luckily, these snips and their straight-cutting counterparts often come in a set. The best way to cut intricate designs in sheet metal is to make a stencil for the design and trace it onto the metal. A hole punch can also help you begin to cut out sections more easily. Sharp, precise, quality tools are important.

What Is the Best Way to Cut Sheet Metal? If you are cutting either straight lines or curves, you don’t have power tools, and you don’t have much sheet metal to cut, your best option is to use a pair of tin snips.

Place the sheet metal on top of the workbench and lay out your pattern using a tape measure, pencil, and straightedge. If your project requires curved cuts, make an easy, economical, and. Discover practical tips & tricks for cutting sheet metal with precision like a professional. Learn how to master the cut. Aviation snips, also called tin snips or compound snips (even though they are different), are the best hand tools for cutting sheets of metal. Cutting in a straight line with tin snips is.

$3.66

cutting curves in sheet metal|flanging tool for sheet metal