3 4 5 axis cnc machining factories Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert . $13.99

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

Junction Boxes from Voltex, Australian supplier of electrical accessories, LED Lighting, Solar products including Junction Boxes & Electrical Accessories, IP56 rated switchgear and other .

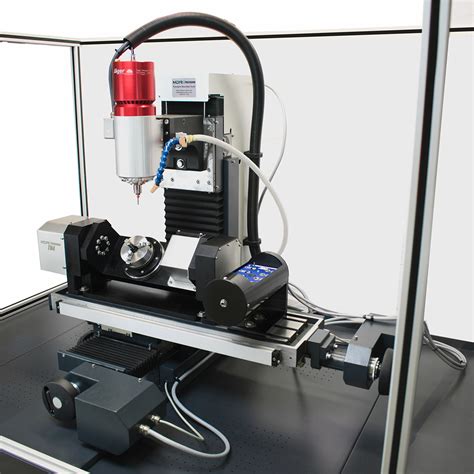

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert . These 4-axis and 5-axis CNC machines can add machining capabilities to workpieces in multiple planes/locations using a single fixture. However, consistent repositioning in 3-axis CNC machining is a factor that .Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to .

These 4-axis and 5-axis CNC machines can add machining capabilities to workpieces in multiple planes/locations using a single fixture. However, consistent repositioning in 3-axis CNC machining is a factor that affects machining deviations.

Chans Machining is a machining factory company with ten years of experience. We have been equipped with lathes and 3-axis, 4-axis, and 5-axis CNC lathes. We can provide milling, turning, metal stamping, processing, etc. The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.Both 3-axis and 5-axis CNC machines have their place in modern manufacturing, offering unique advantages depending on the application. While 3-axis machines are ideal for simpler tasks and offer cost savings, 5-axis machines excel in producing complex parts .

3-Axis Machining: Uses X, Y, and Z axes. Ideal for simpler, planar designs. 4-Axis Machining: Adds an A-axis (rotation around X-axis). Better for intricate profiles. 5-Axis Machining: Uses X, Y, Z, and two rotational axes (B and C). Best for highly complex geometries. Axes of Movement: The movement axes are the primary differentiating factor between the 3, 4, and 5-axis CNC machining. The degree of axes is the direction a cutting tool can move. Therefore, 5-axis CNC machining has the highest degree of cutting tool movement. Part Complexity: Higher-axis CNC machines can design more complex parts.3-axis CNC Milling Machines include axes that can move along the X-axis, Y-axis, and Z-axis dimensions–pretty basic stuff. A 4-axis CNC machine adds a rotating A-axis, enhancing the typical three-axis setup. This allows for more complex part geometries and . CNC machines are often refered to by the number of axes of motion they’re capable of moving in such as 3-axis machine, 4-axis machine and 5-axis machine. We talk about the difference between them.

Compared with four axis CNC machining, five axis CNC machining provides higher flexibility and complexity, enabling more complex geometric shapes to be machined and reducing the need for multiple clamping and repositioning.

what is 5 axis milling

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to . These 4-axis and 5-axis CNC machines can add machining capabilities to workpieces in multiple planes/locations using a single fixture. However, consistent repositioning in 3-axis CNC machining is a factor that affects machining deviations.

how to paint metal box outdoor

Chans Machining is a machining factory company with ten years of experience. We have been equipped with lathes and 3-axis, 4-axis, and 5-axis CNC lathes. We can provide milling, turning, metal stamping, processing, etc. The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.Both 3-axis and 5-axis CNC machines have their place in modern manufacturing, offering unique advantages depending on the application. While 3-axis machines are ideal for simpler tasks and offer cost savings, 5-axis machines excel in producing complex parts .

3-Axis Machining: Uses X, Y, and Z axes. Ideal for simpler, planar designs. 4-Axis Machining: Adds an A-axis (rotation around X-axis). Better for intricate profiles. 5-Axis Machining: Uses X, Y, Z, and two rotational axes (B and C). Best for highly complex geometries. Axes of Movement: The movement axes are the primary differentiating factor between the 3, 4, and 5-axis CNC machining. The degree of axes is the direction a cutting tool can move. Therefore, 5-axis CNC machining has the highest degree of cutting tool movement. Part Complexity: Higher-axis CNC machines can design more complex parts.3-axis CNC Milling Machines include axes that can move along the X-axis, Y-axis, and Z-axis dimensions–pretty basic stuff. A 4-axis CNC machine adds a rotating A-axis, enhancing the typical three-axis setup. This allows for more complex part geometries and .

what does 5 axis mean

CNC machines are often refered to by the number of axes of motion they’re capable of moving in such as 3-axis machine, 4-axis machine and 5-axis machine. We talk about the difference between them.

small 5 axis cnc mill

how to pig tail electric box for a ground

how to open solar panel junction box

The Loxley superior quality enamelled heavyweight empty watercolour box is great for field sketching due to its compactness. The finish is black enamelled on the outside and white on the inside. There is a thumb clip holder on the base for ease of holding whilst painting and the lid when open acts as a mixing palette o

3 4 5 axis cnc machining factories|5 axis machining explained