creo parametric sheet metal tutorial pdf sheet metal tools including live flat pattern preview. • Creo Parametric will open native Solidworks, Inventor and Solid Edge models making it easy to reuse legacy data when upgrading to Creo. . In general, acrylic paint is better suited for painting on hard surfaces such as wood, metal, or glass; while fabric paint is specifically designed for use on fabrics and textile materials. Acrylics are also typically more durable and longer-lasting than fabrics, making them ideal for projects that will see a lot of wear and tear.

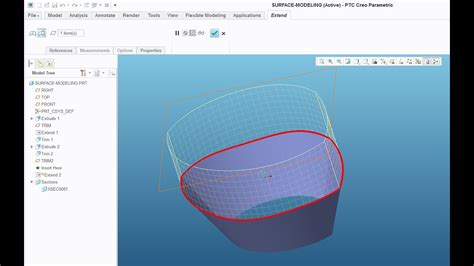

0 · creo surface modeling tutorial PDF

1 · creo parametric user guide PDF

2 · creo parametric user guide

3 · creo parametric tutorial for beginners

4 · creo parametric practice drawings PDF

5 · creo parametric exercises PDF

6 · creo parametric 7.0 tutorial PDF

7 · creo parametric 4.0 tutorial PDF

What is a yellow box junction? The purpose of a box junction is to control traffic flow, and so they are usually found at busy crossroads or T-junctions. Even where there are other traffic control measures in place, like traffic lights, you can sometimes find yourself unable to drive because of stationary vehicles lined up across your path.If you hunt around your neighborhood, you will find a larger box that looks like this: This box is perhaps 4 feet or 5 feet high (1.5 meters). A larger cable with hundreds of wire pairs runs past this point, and one or more 25-pair or 50-pair wires gets its start here.

exterior junction box standoff for clapboard siding

sheet metal tools including live flat pattern preview. • Creo Parametric will open native Solidworks, Inventor and Solid Edge models making it easy to reuse legacy data when upgrading to Creo. . Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (2) This method of working with sheet metal is to create the model within sheet metal .

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation . In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange .This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you .Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the .

extension box electrical outlet

Learn how to use Creo Parametric to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat .The book covers topics like sketching, modeling, assembly, drafting, and surfacing using PTC Creo Parametric 3.0 software. It contains over 800 pages organized across 16 chapters, each covering a different module of the .In Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, or Sweep operations are the most common types of base features. 3.

sheet metal tools including live flat pattern preview. • Creo Parametric will open native Solidworks, Inventor and Solid Edge models making it easy to reuse legacy data when upgrading to Creo. • Faster assembly, real time interference detection and easier 3D sections. Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (2) This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal .

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation of nets for construction of containers, nets of geometrical shapes. This method of working with sheet metal is to create a solid first then In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall.This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.

Learn how to use Creo Parametric to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat patterns, and create detailed drawings.

The book covers topics like sketching, modeling, assembly, drafting, and surfacing using PTC Creo Parametric 3.0 software. It contains over 800 pages organized across 16 chapters, each covering a different module of the software and including tutorials, examples, and .

In Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, or Sweep operations are the most common types of base features. 3.sheet metal tools including live flat pattern preview. • Creo Parametric will open native Solidworks, Inventor and Solid Edge models making it easy to reuse legacy data when upgrading to Creo. • Faster assembly, real time interference detection and easier 3D sections. Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (2) This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal . Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation of nets for construction of containers, nets of geometrical shapes. This method of working with sheet metal is to create a solid first then

In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall.This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.

Learn how to use Creo Parametric to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat patterns, and create detailed drawings.

creo surface modeling tutorial PDF

creo parametric user guide PDF

creo parametric user guide

DXF files, short for Drawing Exchange Format, are one of the most widely used file types in CNC machining. Developed by Autodesk, DXF files allow for the exchange of 2D drawings between different CAD software platforms.

creo parametric sheet metal tutorial pdf|creo parametric user guide PDF