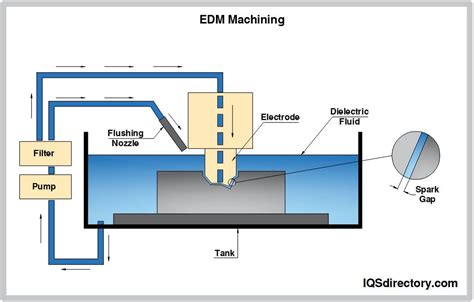

cnc edm spark erosion machine Sinker EDM, also called ram EDM, cavity type EDM or volume EDM, consists of an electrode and workpiece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids. The electrode and workpiece are connected to a suitable power supply. The power supply generates an electrical potential between the two parts. As the electrode appr. RACO Square Ceiling/Wall Electrical Box- the perfect solution for safely housing exposed electrical work. With its round corners and smooth edges, our Drawn Steel Junction Box ensures utmost safety and reliability in exposed work applications.

0 · wire cut edm machine

1 · sinker edm diagram

2 · sinker edm

3 · dielectric sinker edm

I need to move a wall mounted light fixture a few inches left to center the light fixture over a mirror in a bathroom. Is there something available to connect to the original box that will allow me to shift the box so I can attach the new .

Sep 21, 2020 ADV series new generation CNC EDM spark erosion machine is designed for .

Die Sinker EDM Machine, also known as CNC die sinking EDM and CNC Spark .Sinker EDM, also called ram EDM, cavity type EDM or volume EDM, consists of an electrode and workpiece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids. The electrode and workpiece are connected to a suitable power supply. The power supply generates an electrical potential between the two parts. As the electrode appr.

Die Sinker EDM Machine, also known as CNC die sinking EDM and CNC Spark Erosion Machine, is a kind EDM machine that utilizes high frequency power between positive and negative anodes. ADV series new generation CNC EDM spark erosion machine is designed for automation. Equipped with robot and electrode and workpiece store, CNC EDM machine itself can realize small parts, large quantity, and man-free production.

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1] .Die Sinker EDM Machine, also known as CNC die sinking EDM and CNC Spark Erosion Machine, is a kind EDM machine that utilizes high frequency power between positive and negative anodes.

ADV series new generation CNC EDM spark erosion machine is designed for automation, there are many different flexible options.

CNC EDM spark erosion machine is eroding the metal by electrode wire, this method is no contact machining, it can avoid workpiece deformation.WORLD-CLASS EDMs for faster, accurate machining and quality finish, used across 30+ industries and 500+ applications! Know More New Launch! Sparkonix pioneered the EDM Spark Erosion technology in India with the launch of its first indigenous development of Metal Arc Disintegrators, back in the 1960s.The spark erosion process follows a precise sequence where an ionization channel develops into a plasma channel of superheated gas. Material removal occurs through: . The evolution progressed from basic Lazarenko Circuits to modern systems featuring CNC integration, Wire-EDM technology, and advanced capabilities including . EDM machines .Our best selling range of Manual Spark Erosion machines featuring the Fuzzy Logic Control System - its probably the least complicated EDM machine on the market. Our entry level CNC machines, easy to operate, setup and program giving improved efficiency to your workshop.

CHAPTER 1 Definiation Of Spark Erosion The principle of Spark Erosion machining process is to remove excess metal using electrical corrosion (pulsed spark discharge) between the tool and the workpiece, in order to achieve the desired size, shape and surface quality of the workpiece.

metal c clamp bracket

wire cut edm machine

Electric discharge machining, also known as spark erosion, electro-erosion or spark machining, is a process of metal removal based on the principle of erosion of metals by an interrupted electric spark discharge between the electrode tool cathode and the working anode. ADV series new generation CNC EDM spark erosion machine is designed for automation. Equipped with robot and electrode and workpiece store, CNC EDM machine itself can realize small parts, large quantity, and man-free production.

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1] .Die Sinker EDM Machine, also known as CNC die sinking EDM and CNC Spark Erosion Machine, is a kind EDM machine that utilizes high frequency power between positive and negative anodes. ADV series new generation CNC EDM spark erosion machine is designed for automation, there are many different flexible options.

CNC EDM spark erosion machine is eroding the metal by electrode wire, this method is no contact machining, it can avoid workpiece deformation.

WORLD-CLASS EDMs for faster, accurate machining and quality finish, used across 30+ industries and 500+ applications! Know More New Launch! Sparkonix pioneered the EDM Spark Erosion technology in India with the launch of its first indigenous development of Metal Arc Disintegrators, back in the 1960s.The spark erosion process follows a precise sequence where an ionization channel develops into a plasma channel of superheated gas. Material removal occurs through: . The evolution progressed from basic Lazarenko Circuits to modern systems featuring CNC integration, Wire-EDM technology, and advanced capabilities including . EDM machines .Our best selling range of Manual Spark Erosion machines featuring the Fuzzy Logic Control System - its probably the least complicated EDM machine on the market. Our entry level CNC machines, easy to operate, setup and program giving improved efficiency to your workshop.

CHAPTER 1 Definiation Of Spark Erosion The principle of Spark Erosion machining process is to remove excess metal using electrical corrosion (pulsed spark discharge) between the tool and the workpiece, in order to achieve the desired size, shape and surface quality of the workpiece.

sinker edm diagram

metal cash box with lock in india

Floating-shelf hardware types include floating-shelf brackets that mount to the wall and then invisibly hold the shelf in place. These sturdy metal brackets have powder-coated finishes for added durability. Select from white, black and silver and other colors to .

cnc edm spark erosion machine|sinker edm