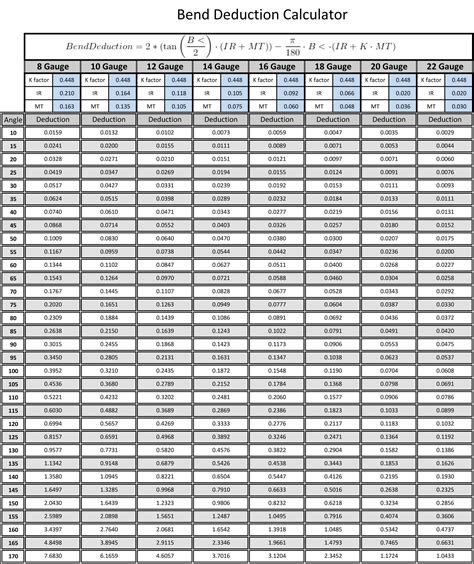

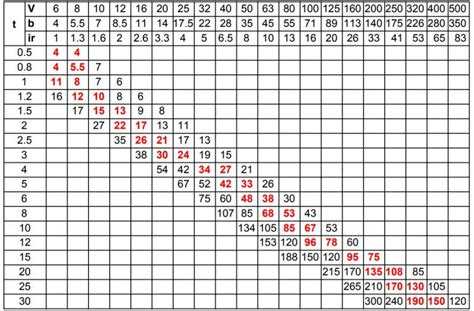

bend deduction formula in sheet metal Let’s start with the formulas for bend allowance and bend deduction. Bend Allowance = Angle (Π/180) (BendRadius+KFactor (Thickness)) Bend Deduction = 2 (BendRadius+Thickness)

Junction boxes are often located on walls near compressors, pumps or large pieces of equipment. In addition, junction boxes are often used on the roof of commercial buildings to provide access to circuits associated with air conditioning units and ventilation fans.

0 · stainless steel bend deduction chart

1 · sheet metal bending allowance charts

2 · sheet metal bend deduction chart

3 · sheet metal bend calculation formula

4 · how to calculate bend length

5 · how to calculate bend deduction

6 · how to calculate bend allowance

7 · bend deduction chart pdf

CENTRAL JUNCTION BOX is what the fuse box is called on the 2003 Expedition as the Gem and fuse box appear to be integrated.

The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness . A bend deduction (BD) is the value subtracted from the flat blank for each bend in the part, and there may be more than one. Bend deductions differ depending on the part itself, different bend angles, and/or inside radii. Total bend deduction in sheet metal parts can be calculated by using the following formula: Sheet Metal Flat Length = Length A + Length B – Bend Deduction. Bend Deduction = . Bend Deduction is actually the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component, in order to get the correct length of the flat pattern that you need .

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Let’s start with the formulas for bend allowance and bend deduction. Bend Allowance = Angle (Π/180) (BendRadius+KFactor (Thickness)) Bend Deduction = 2 (BendRadius+Thickness)

Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming.

Considering the Bend Deduction and Bend Allowances is a critical first step in designing sheet metal parts as it affects nearly every following step in the fabrication process. More so, it will allow you to achieve the correct size . Our bend deduction calculator helps you calculate the correct values for your sheet metal bending projects, ensuring accurate results and minimal waste. Try it out for free today!The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K). A bend deduction (BD) is the value subtracted from the flat blank for each bend in the part, and there may be more than one. Bend deductions differ depending on the part itself, different bend angles, and/or inside radii.

Total bend deduction in sheet metal parts can be calculated by using the following formula: Sheet Metal Flat Length = Length A + Length B – Bend Deduction. Bend Deduction = Length A + Length B – Sheet Metal Flat Length Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time. Bend Deduction is actually the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component, in order to get the correct length of the flat pattern that you need to create for that component. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Let’s start with the formulas for bend allowance and bend deduction. Bend Allowance = Angle (Π/180) (BendRadius+KFactor (Thickness)) Bend Deduction = 2 (BendRadius+Thickness)

Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Considering the Bend Deduction and Bend Allowances is a critical first step in designing sheet metal parts as it affects nearly every following step in the fabrication process. More so, it will allow you to achieve the correct size and dimensions needed in the flat pattern. Our bend deduction calculator helps you calculate the correct values for your sheet metal bending projects, ensuring accurate results and minimal waste. Try it out for free today!The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K).

A bend deduction (BD) is the value subtracted from the flat blank for each bend in the part, and there may be more than one. Bend deductions differ depending on the part itself, different bend angles, and/or inside radii.Total bend deduction in sheet metal parts can be calculated by using the following formula: Sheet Metal Flat Length = Length A + Length B – Bend Deduction. Bend Deduction = Length A + Length B – Sheet Metal Flat Length Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time. Bend Deduction is actually the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component, in order to get the correct length of the flat pattern that you need to create for that component.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Let’s start with the formulas for bend allowance and bend deduction. Bend Allowance = Angle (Π/180) (BendRadius+KFactor (Thickness)) Bend Deduction = 2 (BendRadius+Thickness)

Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming.

electrical back box plastic

stainless steel bend deduction chart

sheet metal bending allowance charts

Metoro 16-Gauge Mild CRS Steel Sheet - Formable, Weldable, Magnetic, Smooth Surface - Industrial-Grade Metal Plate for DIY Projects, Fabrication, and More. (2, .060 x 12 x 8) 4.3 out of 5 stars

bend deduction formula in sheet metal|sheet metal bending allowance charts