how to read sheet metal blueprints Learning to read blueprints can be hard. That’s why we’ve broken down the process into bite size chunks. All of the basic components of an engineering drawing are . Find Exterior electrical boxes at Lowe's today. Shop electrical boxes and a variety of electrical products online at Lowes.com.

0 · sheet metal shop drawings

1 · sheet metal drawing

2 · sheet metal box layout

3 · sheet metal box fabrication

4 · sheet metal box drawing

5 · sheet metal box design guide

6 · sheet metal box design

7 · manufacturing blueprint symbols

As can be seen, metal roofing and siding trims are essential components of residential and commercial structures. They provide weather protection, allow for proper ventilation, and enhance the aesthetic appeal of a space.

sheet metal shop drawings

Learning to read blueprints can be hard. That’s why we’ve broken down the process into bite size chunks. All of the basic components of an engineering drawing are .How to read a tolerance block; Other names for a tolerance block; Want to learn .Whether you’re new to machining, want to figure out that never before seen .

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this . Basic Guide to Blueprints: How to Read a Blueprint. Written by MasterClass. Last updated: Jun 7, 2021 • 7 min read. Whether you're a homeowner with a hands-on approach to home renovation or a professional .

cnc machining precision parts factory

a video series on blueprint reading for welders and fabricators. From basic lines and views and navigating a print.Blueprints are the most important means of communicating the design of metal fabrication parts between customers, engineers, and shop floor personnel. The ability to read blueprints is an important skill for everyone involved in the .

This is the first of a 5 video series on blueprint reading for metal stud and drywall.With a bit of guidance and a few helpful tips, anyone can read steel building blueprints. Steel Blueprint Tips: 1. Blueprint Cover Pages. Take the time to understand the cover pages of your design drawings. The cover page includes . In this mini-series, we're going to cover Construction Blueprints from start to finish. Showing you guys everything you need to know along the way.

When you’re trying to read a blueprint, start by reading the title and revision blocks provided on the first page. Then, read the legend to understand the numbers and symbols used in that specific blueprint.This textbook presents a step-by-step method for learning to read sheet metal drawings. The primary objective of the textbook is to explain and illustrate the methods and techniques used by the sheet metal draftsman to convey the . It is important to know How to read Structural Steel Drawings, and it isn't something that is covered during university. When starting out reading structura.Learn the different sections. Arch,mech,elec,civil,site plans,grading plans... Then is always read the details drawings and the notes pertaining to the project. Finally find a shit load of drawings with tender forms and try to do some quantity estimates and see how close you can get. All the experience will come from always looking at plans.

ERIC ED391910: Blueprint Reading for Sheet Metal Workers. Training Guide. by ERIC. Publication date 1995 Topics ERIC Archive, Adult Education, Adult Vocational Education, Behavioral Objectives, Blueprints, Competency Based Education, Engineering Drawing, Learning Activities, Machine Tool Operators, Orthographic Projection, Sheet Metal Work,

Get a book “how to read blueprints”. Used bookstores usually have them. . So, you should be able to flip to sheet M-600 and pretty quickly find the make/model/CFMs/HP of that exhaust fan. If you wanted to know how a particular wall was supposed to be built, you would first look at A-100 and there should be some indication that it's a W1 . A sheet metal fabricator works with thin metal sheets, installing and fabricating them into various products. They typically collaborate with a team to complete tasks such as trimming, buffing, smoothing, and grinding metal surfaces. Reading blueprints and selecting the appropriate metal gauges for projects are crucial parts of their job. Link to Prints: https://www.dropbox.com/sh/ctaigery6v2o0u3/AAAxFnC1LFlH5ei9hAp1BJv7a?dl=01:20 How to Read Residential Blueprints 14:52 How to Read Commercia. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

How to read a metal roofing take-off report and order material based on that information? Comment below to have your question answered on a future episode!**. If you're thinking about getting into construction or if you're already in construction you have to know how to read a set of construction drawings/blueprint. Benefits of Reading Blueprints for CNC Machines. Reading blueprints for CNC machines has several benefits. First, it enables machinists to produce parts and components with precision and accuracy, reducing the chances of errors and defects. Second, it enables them to program the CNC machine accurately, reducing setup times and increasing .

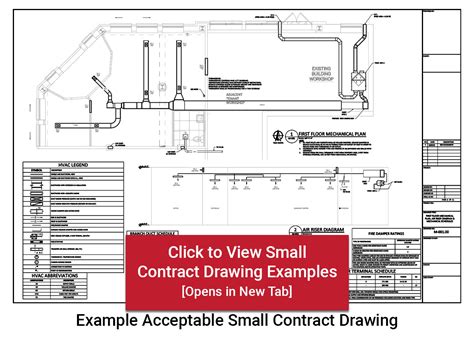

LINK TO FREE PLANS BELOW! The Sheet Metal Brake I always wanted: 36" glory, cantilever locking mechanism, adjustable fingers, weighs as much as I do! (NOTE: . This is where the sheet metal ductwork and HVAC Piping will be shown for each floor and area of the building. . Piping are shown on separate drawings to allow for clarity and avoid having drawings that are congested and hard to read. In addition to the floor plans for each floor in the building you will also have a Roof Plan that shows that .

sheet metal drawing

sheet metal box layout

In this video, you will see me explaining the basic steps required to measure and mark out on sheet metal in. These steps are transferable through any sheet .

Sheet Metal Blueprint Reading for the Building Trades [Zinngrabe, Claude J.] on Amazon.com. *FREE* shipping on qualifying offers. Sheet Metal Blueprint Reading for the Building TradesIf you are new to reading plans or metal fabrication measurements, this blog can help you understand fabrication blueprints. . Laser - Fiber - Sheet; Laser - Fiber - Tube + Shapes; Pipe Facing, Beveling & Threading; Pipe Rotators Pipe . Wire gauges are completely different than sheet metal gauges. I concurr that sheet metal gauges are industry/material specific. I see no problem with specifying the sheet metal gauge on a drawing since that is how you are . Reading blueprints correctly also saves costs by getting projects done the right way in the first attempt. Unfortunately, a large number of welders have a hard time reading blueprints correctly. . In case the groove is created .

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Construction blueprints are technical drawings created by architects, engineers, and designers to put all the construction specifics of a house in one package to which the builder can refer as they construct the house. Although a package of blueprints can be daunting, as many as 50 pages long, the concept of the blueprint is simple: It is a series of two-dimensional .

Hardworking Sheet Metal Mechanic with 5+ years of experience in working with sheet metal, reading blueprints and performing maintenance and repair of sheet metal working machinery. Possess a strong understanding of sheet metal manufacturing processes and procedures. Experienced in operating sheet metal equipment, such as shears, grinders . Blueprints are the complete set of drawings that show what a designer wants a building to look like. These drawings are made to an exact “scale” (a ratio of size; the length of a line on the drawing equals a proportional length on the building) and include dimensions, as well as plenty of detail on material choices and installation directions.

G Sheets (General Sheets): Include the cover sheet, plan index, and site plan showing the building’s placement, property boundaries, landscaping, and utility lines. A Sheets (Architectural Plans): Provide floor and roof plans, elevations, and detail drawings.Show dimensions, wall layouts, door locations, and roofing materials. S Sheets (Structural Engineering Plans): Focus . Alright, guys. So, I'm gonna take a minute here and just kinda give a brief overview of what it's like uh to get a set of trust plans when you're building a house and uh just kinda go over all the details and .

This video explain about how to understand steel structural beam drawing Fabrication drawing information (English)If you want to more video about. Structur.A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create. This article will focus on how to prepare accurate and easy to interpret sheet metal drawings so .

Sheet metal mechanics use these specifications to determine the sequence and methods of fabricating, assembling, and installing sheet metal products. They also use them to select the right gauges and types of sheet metal or non-metallic material. For example, they might read blueprints or sketches to decide the proper method of installation.What are some books or references that will help me learn to read duct blueprints? Thank you Share Sort by: Best. Open comment sort options. Best. Top. New. . Sheet Metal, by Leo A Meyer, Sheet Metal Skills by Rex Miller, Modern Welding (11TH Edition), and the holy grail of all sheet metal reference books, Audels Sheet Metal Workers Handy .

cnc machining polycarbonate

The national average metal siding cost is $11,171, with typical projects ranging between $3,741 and $18,602. Depending on square footage, materials used and labor costs, you might pay as little as $500 or as much as $35,000.

how to read sheet metal blueprints|sheet metal shop drawings