sheet metal processing techniques Dumaco Oss, previously Heurkens & van Veluw, specializes in metal processing. We supply sheet-metal, tube and pipe parts, with orders ranging from single pieces to welded assemblies. Our team of 130 people is armed with the vary latest and fastest laser-cutting machines, press brakes and welding robots.

Metal Arts specializes in high-quality structural and miscellaneous steel fabrication, serving general contractors and other customers in multiple states. Please contact us at (316) 942-7958 to discuss your project or to request a quote!1711 South Knight Street, Wichita, KS, USA. 316-706-1443 or

[email protected]

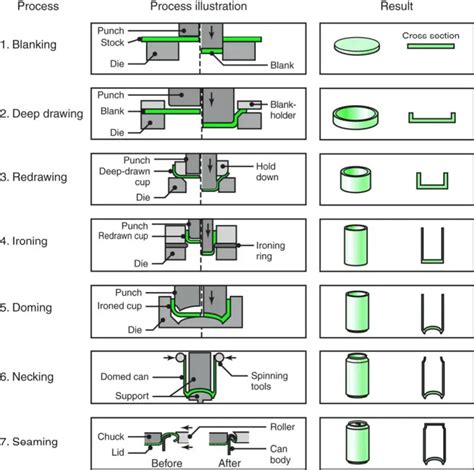

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

Merely being a metal box doesn't ground it; there'd need to be a wire or metal pipe (conduit) back to the panel. However, you probably know cables come in black, white and optional red (and you're forced to use those colors for everything, which is not fun).

Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost . Have you ever wondered how everyday items like electronics, cars, and medical devices are made so precisely? The answer lies in sheet metal fabrication. This blog delves into 24 key techniques, from bending and laser . The factory extensively utilizes pressure riveting techniques for fastening sheet metal components, primarily employing riveting studs, nuts, and screws. . Cold Bending Forming Technology Cold bending forming .

Looking for the best sheet metal joining techniques? Our comprehensive guide provides all the information you need to choose the right technique for your project. . Commonly used connection methods in sheet .Mevar: all sheet metal processing techniques We are a company that embodies multiple skills in the field of sheet metal processing. We offer our customers all the techniques available in the sector: prototyping, moulds design and .Dumaco Oss, previously Heurkens & van Veluw, specializes in metal processing. We supply sheet-metal, tube and pipe parts, with orders ranging from single pieces to welded assemblies. Our team of 130 people is armed with the vary latest and fastest laser-cutting machines, press brakes and welding robots. Sheet metal fabrication is the process of transforming flat metal sheets into products. Metal fabrication inclues cutting, punching, bending, etc. . Often times a variety of fabrication techniques can be used to achieve a similar end result. But the right choice still exists, depending on the costs and needs.

Welcome to Michaels Sheet Metal, a leading provider of innovative sheet metal solutions for the construction industry. This article will explore the various sheet metal processing techniques that play a crucial role in construction projects. At Michaels Sheet Metal, we are committed to delivering superior results that meet the unique needs of our clients, leveraging .

various sheet metal processes

For custom production of sheet metal parts we use the highest quality machines and the most modern technologies. We provide not only components, assemblies and finished products, but also comprehensive and tailor-made solutions based on specific client’s requests. . Sheet metal processing techniques we offer: Punching; Bending; Sheet Metal . Turnkey Metal Processing Services. Understanding Metal Fabrication Techniques: What is the Sheet Metal Bending Method? Sheet metal bending allows the creation of diverse part geometries without the need for extensive tooling, thus offering quick lead times, high repeatability, and automation. Bending is particularly advantageous for low to . In the second chapter of our sheet metal processing guide, we explore various forming techniques that are crucial for creating the desired shapes and features in sheet metal components. Section 2.1 discusses the process of partial shearing, which involves cutting sheet metal partially to create specific shapes or features without completely .Take a look at the metal processes summary, learn about the common types of metal processing techniques and methods +86 13728265788 [email protected] BOOK NOW Login. Our Services. CMM Services. Form Tracing; Part Sorting; 3D Laser Scanning; . Deformation process including metal forming and sheet metalworking. Large deformations and shape .

Sheet metal forming is commonplace in a variety of industries and everyday items. Read on to find out everything you need to know about sheet metal forming, how it works, and where it’s used. . There is very minimal post-processing needed with this method, and hardly any waste. It is commonly used in automotive, aerospace, and electronics. .

types of sheet metal process

Sheet metal processing is a complex and precise operation used in various industries, including automotive, aerospace, and construction. . Regular tool inspection and replacement can prevent dull blades from creating burrs. Additionally, post-processing techniques such as deburring or grinding can help smooth out any rough edges. By using the right methods and techniques, sheet metal fabricators can create high-quality products that meet all required specifications and standards. Various methods, including mechanical fastening, welding, and adhesive bonding, can accomplish the assembly. . They also support easy sheet metal processing methods due to increased ductility.

Different sheet metal components require multiple sheet metal processing techniques that help achieve the desired shape. A skilled workforce knows when to use a sheet metal bending machine or .

The cutting-edge technology put in place by Minifaber, specialized in metalworking processes, allows it to accurately cut and bend sheet metal Cutting and bending sheet metal: cutting techniques. According to the metal to be .Likewise, using sheet metal fabricating techniques, you can make various cut outs for cable connections, such as glass windows, LED panels, light pipes, and HDMI. When to Use Sheet Metal Processing. 1. Low Part Volume. When you need a relatively small quantity of parts or components, sheet metal processing can be a cost-effective choice.

Sheet metal finishing enhances both the appearance and functionality of metal parts. The right finish prevents rust, increases wear resistance and creates an attractive surface texture. Modern finishing techniques like powder coating, anodizing, and plating deliver reliable protection while meeting precise aesthetic requirements.Advanced Sheet Metal Processing Techniques in China. In recent years, China has made significant advancements in sheet metal processing, leveraging sophisticated machinery, skilled labor, and innovative techniques. Let's delve into some of the most prominent sheet metal processes prevalent in the Chinese manufacturing landscape: 1. Laser Cutting: Using advanced sheet metal processing techniques, Sinoway is able to manufacture lightweight parts without compromising durability. Key Sheet Metal Processing Techniques in Aerospace. Sinoway employs several sheet metal processing methods to create high-quality, reliable aerospace components. Here are some of the essential techniques that .

electrical floor box sizes

This article uncovers 26 advanced techniques used in metal forming, from traditional methods like forging and rolling to modern innovations such as metal injection molding and selective laser melting. . Want to slash costs and boost profits in sheet metal processing? In today's competitive market, accurate cost calculation is crucial for .This can be an advantage, but it can also create longer processing times. For example, a laser cutter cannot make tiny holes, so a drilling or punching process would have to be included. . When joining and fastening sheet metal, one of the go-to techniques is definitely welding, which involves fusing parts together at high temperatures.

Forming and bending are essential techniques in sheet metal fabrication that allow for the creation of three-dimensional shapes. The brake press is a commonly used tool for bending and forming sheet metal. It uses a punch and die set to create angular bends at specific locations. The bending process requires precise calculations and adjustments . In fact, the processing accuracy of various sheet metal components is not high, and most assemblies require adjustments to be completed. There are generally two methods for assembling spherical caps into cylindrical bodies: one is the covering method, where the head is cut to the net material (4mm smaller than the design diameter). Metal processing techniques - Download as a PDF or view online for free. . Sheet metal drawing and wire 2) Bar drawing 3) Tube drawing. 12. Thermal Treatment Thermal treatment is a process in which the temperature of the material is raised or lowered to alter the properties of the original material. Most thermal-treating processes are based .

Market Leading Producer Of Sheet Metal Alloy Welcom To Metal proc Market Leading Producer Of Sheet Metal Alloy Detailed Processing. Our website showcases the artistry and craftsmanship of metalworking through detailed descriptions of various processing techniques. From forging and casting to welding and shaping, we provide in-depth explanations . The processing technology of sheet metal parts is a complex issue. This post provides a brief overview of the basic principles of setting up a fabrication technique for general sheet metal parts, with the aim of identifying the basic method for setting up a . It is crucial to understand the various sheet metal fabrication techniques available to fully comprehend the process of forming multiple components utilizing sheet metal. The processing procedures for sheet metal make the transformation of two-dimensional metal sheets into three-dimensional, functional pieces. The following list contains the .

electrical floor boxes lowes

types of sheet metal fabrication

WSM Industries is the leader in HVAC supplies. We manufacture pipe, duct, spiral pipe and fittings, and carry a comprehensive supply of flat sheets, venting, registers and grills, insulation supplies, linesets, and more.

sheet metal processing techniques|basic sheet metal fabrication techniques