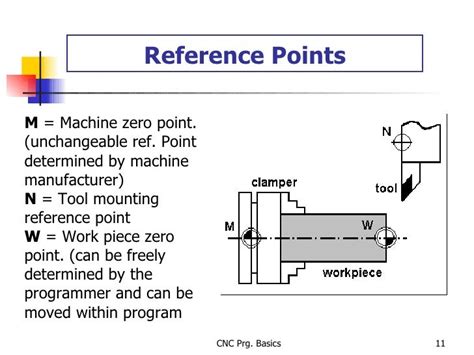

cnc lathe machine zero On CNC lathes (including both front and rear lathe types with two+ axis models), the machine zero is located at the furthest distance from the lathe center line in each axis (X . Discover the 10 essential CNC machine cutting tools you need to build precise, high-quality parts. Learn the features and benefits of each tool.

0 · cnc lathe zero reference point

1 · cnc lathe zero position

2 · cnc lathe zero offset

3 · cnc lathe zero

4 · cnc lathe setting zero

5 · cnc lathe parts

6 · cnc lathe offset

7 · cnc lathe 0 turret position

Currently, there are three common types of steel box trusses widely used in construction: steel box trusses for tiled roofs, steel lattice roof trusses, and galvanized steel box trusses. 1.1. Steel box trusses for tiled roofs. This structure follows the traditional lean-to-tile supporting structure, a proven principle in the tile support .

cnc lathe zero reference point

waterproof surface junction box

On CNC lathes (including both front and rear lathe types with two+ axis models), the machine zero is located at the furthest distance from the lathe center line in each axis (X . Zeroing a CNC lathe with Fanuc controls is an essential step before starting any machining operation. By zeroing the lathe, you establish a reference point for all subsequent movements and ensure accurate and . Unlock the power of the G28 G-Code for your CNC machine! This guide covers the G28 command to safely return to zero position and ensure precise machining.Accurate machine zero is the foundation for achieving enhanced precision in CNC machining. We will explore how machine zero impacts various machining operations and how it contributes to .

In the drawing below, for example, notice how the Z-axis of the part is horizontal and the Z-zero is on the tailstock side of the part / drawings, exactly as it would be when cutting it in the machine.

Setting zero on a CNC lathe is a crucial step in ensuring accurate and precise machining. Without properly setting zero, the machine may not know where the workpiece is located, leading to incorrect cuts and wasted material. On CNC lathes (including both front and rear lathe types with two+ axis models), the machine zero is located at the furthest distance from the lathe center line in each axis (X-origin of the lathe) and also at the furthest distance from the . Zeroing a CNC lathe with Fanuc controls is an essential step before starting any machining operation. By zeroing the lathe, you establish a reference point for all subsequent movements and ensure accurate and reliable machining. Unlock the power of the G28 G-Code for your CNC machine! This guide covers the G28 command to safely return to zero position and ensure precise machining.

Accurate machine zero is the foundation for achieving enhanced precision in CNC machining. We will explore how machine zero impacts various machining operations and how it contributes to achieving tight tolerances and exceptional surface finishes.

In the drawing below, for example, notice how the Z-axis of the part is horizontal and the Z-zero is on the tailstock side of the part / drawings, exactly as it would be when cutting it in the machine. Before moving and cutting a block, the CNC machine needs to know where to start, the start position is the part zero used in programming. In this article, here are three ways for how to set zero point in CNC or how to zero a CNC mill with stock before machining.The machine zero point refers to the origin of the coordinate system on a CNC machine. It is the point from which the machine determines the positions of all tools and workpieces. Setting the zero point correctly is crucial for accurate machining, reducing .

cnc lathe zero position

We use a floating zero referred to as the part zero or part origin. We touch off the face and diameter, and store the offset from the machine zero in X and Z register of the Tool Offsets Page. (Not the same as mill which uses G54!) Normally most of the X values are going to be positive in a part program.What is G Code G28? G28 command instructs the CNC machine to return rapidly to the Absolute Zero (Datum) point of the machine. The motion can be direct or via an intermediate coordinate. Syntax A: G28 – The machine will move directly to the zero point. Setting zero on a CNC lathe is a crucial step in ensuring accurate and precise machining. Without properly setting zero, the machine may not know where the workpiece is located, leading to incorrect cuts and wasted material. On CNC lathes (including both front and rear lathe types with two+ axis models), the machine zero is located at the furthest distance from the lathe center line in each axis (X-origin of the lathe) and also at the furthest distance from the .

Zeroing a CNC lathe with Fanuc controls is an essential step before starting any machining operation. By zeroing the lathe, you establish a reference point for all subsequent movements and ensure accurate and reliable machining.

Unlock the power of the G28 G-Code for your CNC machine! This guide covers the G28 command to safely return to zero position and ensure precise machining.Accurate machine zero is the foundation for achieving enhanced precision in CNC machining. We will explore how machine zero impacts various machining operations and how it contributes to achieving tight tolerances and exceptional surface finishes.

In the drawing below, for example, notice how the Z-axis of the part is horizontal and the Z-zero is on the tailstock side of the part / drawings, exactly as it would be when cutting it in the machine. Before moving and cutting a block, the CNC machine needs to know where to start, the start position is the part zero used in programming. In this article, here are three ways for how to set zero point in CNC or how to zero a CNC mill with stock before machining.The machine zero point refers to the origin of the coordinate system on a CNC machine. It is the point from which the machine determines the positions of all tools and workpieces. Setting the zero point correctly is crucial for accurate machining, reducing .We use a floating zero referred to as the part zero or part origin. We touch off the face and diameter, and store the offset from the machine zero in X and Z register of the Tool Offsets Page. (Not the same as mill which uses G54!) Normally most of the X values are going to be positive in a part program.

In this article, we’ll discuss the four different types of steel, along with how they’re classified, the various steel grades and the methods of heat treatment used to improve steel’s mechanical properties.

cnc lathe machine zero|cnc lathe 0 turret position