how to flange sheet metal In this Solid Edge tutorial you will learn how to create flanges for synchronous sheet metal parts within the Solid Edge Sheet Metal environment. This will help you get the most from. Wholesale Sheet Metal has been a trustworthy and reliable source of heating, ventilating, air conditioning and sheet metal products in our market for over 35 years. Our courteous and .

0 · sheet metal minimum flange length

1 · sheet metal guidelines pdf

2 · sheet metal enclosure design guide

3 · minimum bending radius sheet metal

4 · hole to distance sheet metal

5 · flange length in sheet metal

6 · flange calculation sheet

7 · extruded hole in sheet metal

Get instant quotes on custom metal and plastic machined parts with our Online CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and .

0:00 / 11:32. Find The Tools I Use Here -https://www.amazon.com/shop/thefabforums*As an Amazon Associate I earn from qualifying purchases*On this episode of The Fab Forums.Discover the essential guide to sheet metal flange. Learn about types, uses, materials, and manufacturing processes in detail. A sheet metal flange can be a projection, a rim, or both. In this Solid Edge tutorial you will learn how to create flanges for synchronous sheet metal parts within the Solid Edge Sheet Metal environment. This will help you get the most from.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

If you require flanges shorter than the minimum acceptable flange height, Approved Sheet Metal can provide a solution. They can use the "Perfect Fit Flange Formula" to design a longer flange and then cut it down using an . Folding machines, also known as folding brakes, box brakes, and pan brakes, clamp the sheet metal workpiece on a stationary bed and swing the skirt of the brake—like a leaf on a hinge—to create the bent flange. Folders .Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and .To Work with Flanges in Sheet Metal. A flange can be along an edge or loop, or identical to an existing face. What's New: 2021. Tip: In some cases, a flange can merge into an existing face. .

The Flange feature allows you to create a wall for each edge selected on a sheet metal model, connected by a bend. Click the Flange feature tool from the Part Studio toolbar. Select the Edges or side faces to flange. How to edit a sheet metal rule or create a new one in Fusion. A new thickness value may be desired. Switch rules in an existing design Click the Sheet Metal Rule icon to change the rule in use in the current design. Edit . The reason why the flanges cannot be created on the other end is due to the non-perpendicular detail face there. Most of Inventor sheet metal features operate under the assumption that the side face is always . Thank you for u r time and answer but with loft flange can we add flange on chord segment. for more information please see below picture . I want to add flange on yellow marked edge. If it is possible with loft flange can you .

Optional: Check Override Rules to override one or more values from the Sheet Metal Rule. Click OK. The contour flange is created and joined to the sheet metal body in the canvas, bending a the selected sheet metal edge. A Flange feature displays in the Timeline. Create a lofted flange. On the Sheet Metal tab, select Create > Flange. Watch this video and more in the "Solid Edge Sheet Metal Tutorials" playlist:http://www.youtube.com/watch?v=vwGSpl130XY&list=PLWZ_kkGONSI9 .

In our last update the team did a great job adding in the join ability to the flange tool. You can select the edge first and then the sketch for the join profile or the opposite. As with other Fusion 360 features, you can add edges by holding Command (mac) or Ctrl (PC). *** To join multiple edges, the profile sketch must intersect the flange it is joining. The team hopes .This simple workflow shows how easy and quick it is to shorten the length of a flange in sheet metal design. Resource Center > Tech Tips > Tech Tip: How to Create Partial Sheet Metal Flanges in Onshape. 09/27/2022 CAD. Tech Tip: How to Create Partial Sheet Metal Flanges in . On this episode of Make It Kustom, I install a 1980s Jaguar gas cap in a 1948 Plymouth fender using simple tools to stretch the flange of the Plymouth sheet . Users are unsure how edit the extent of a flange along a particular edge. This must be changed within the "Edit Flange" dialog box. The screencast below details this process How to edit flange extents in the sheet metal workspace of Fusion . How to edit flange extents in the sheet metal workspace of Fusion. Autodesk Support. Oct 14, 2024 .

A deep return flange is created when a second bend is produced near the first bend; also, the return flange’s length is greater than or equal to the flange created by the second bend (see Figure 1). This causes the first bend to arc back toward the second bend line. You can create your sketch like as picture and use "Contour Roll Comand" first u should choose profile and 2nd you should choose axis then you can create. GET THE AIR FLANGE TOOL HERE http://www.amazon.com/gp/product/B007QV7WW0/ref=as_li_tl?ie=UTF8&camp=1789&creative=390957&creativeASIN=B007QV7WW0&linkCode=as2&.

Optional: Check Override Rules to override one or more values from the Sheet Metal Rule. Click OK. The contour flange is created and joined to the sheet metal body in the canvas, bending a the selected sheet metal edge. A Flange feature displays in the Timeline. Create a lofted flange. On the Sheet Metal tab, select Create > Flange. Hi, Former Creo user here, although I've been using Inventor for the last 3 months and getting the hang of it. However. I just can't figure out how to model this one particular sheet metal part in Inventor. The bulk of the part is a shape that blends from an oval-ish profile on the bottom to a circular profile on the top. Contour Flanges in Fusion 360 don't necessitate a special feature. Watch this QUICK TIP to learn how to make these flanges quickly, and easily. GET STARTED |.

How to use LOFTED FLANGE and Flat Pattern in Inventor Sheet Metal - Autodesk Inventor#inventor #inventorsoftware &autodesktutorial Below are some good produc.When learning the art of metal forming and fabrication one of the first skills many of us learn is how to “Flange” sheet metal. While flanging straight edges can be done with a metal brake, curved panels which are more common on classic . On this episode of Make It Kustom, I’m showing you examples on how to tip curved flanges using hammer forming techniques as well as the bead roller and the d. See more at: http://www.goengineer.com/ or http://www.goengineer.com/products/solidworks/ or http://www.goengineer.com/govideochannel/Learn about the ability.

the box electric guitar

In today's video we will discuss how to Tip a Flange on a Radius. Tipping a Flange on a Curve is an excellent way to recreate original components such as fe. Solidworks Sheet Metal Swept Flange In This Tutorial Of Solidworks Sheet metal we will learn how to use sketched bend and swept flange in Solidworks so watch.Solidworks sheet metal is a great way to create, design, and prototype sheet metal parts. It is used in a wide range of industries including automotive, aerospace, and more. There are two types of Solidworks sheet metal: the Flattened Pattern and the Sheet Metal Forming. The Flat Pattern is used when you want to create a 2D pattern of the 3D model.

This Solid Edge sheet metal tips and tricks looks at a couple of solutions for creating a curved flange, but only one will completely flatten. The Solidworks sheet metal tutorial provides a step-by-step guide on how to create a swept flange command. This tutorial will teach you how to create the cor.

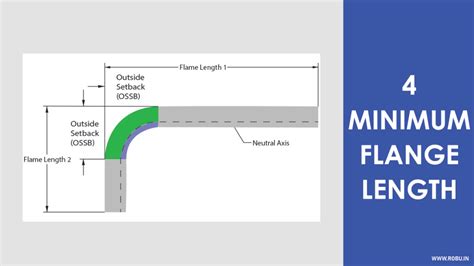

I occasionally have to make non-orthogonal corners in sheetmetal panels. For example, sketch a trapezium, make a face. make two flanges on one of the obtuse corners, now make return flanges on the flanges...how do you get the corner mitred??? I used to have a way of cheating on these but can't remember it. Perhaps someone who does a lot more sheetmetal .On this episode of Make It Kustom, I BUILD a shrinker tool from scrap metal Follow along to learn how to make your own sheet metal shrinking tool.Join this c. Design Guide No. 1: Focus on Sheet Metal Flange Depth. In the fab shop, the V-die width in the press brake limits the size of the flange that can be bent. During bending, the sheet metal must bridge fully across the V die (see Figure 2). The V die is usually selected to be 5x to 8x the workpiece thickness. Brittle materials may require V dies .

sheet metal minimum flange length

sheet metal guidelines pdf

sheet metal enclosure design guide

Choose RapidDirect for comprehensive online sheet metal fabrication services. With over 40 sets of advanced machines—including laser cutters, bending machines, and welders—our China-based network handles everything from .

how to flange sheet metal|sheet metal enclosure design guide