how to roll sheet metal parts in solidworks By far, the most common way to purchase metals for end use is as “sheet metal”, which is defined as a flat metal less than ¼” thick (about 3 gauge) and going all the way down to as thin as 0.0125” (or 30 gauge). Sheet metal can be bent, rolled, formed, stamped, slit, spun and generally fashioned into just . See more Retailers from Hobby Lobby to Walmart are stocking their shelves with wire metal baskets and oversized signs that say “Groceries.” Joanna Gaines has a very particular sense of style. Here’s .

0 · solidworks unfold sheet metal

1 · solidworks unbend sheet metal

2 · solidworks sheet metal pdf

3 · solidworks sheet metal examples

4 · solidworks sheet metal drawing pdf

5 · solidworks sheet metal cylinder

6 · sheet metal modeling in solidworks

7 · folding sheet metal in solidworks

ANSI and ISO Twist drill size chart Fractional and Metric Sizes per. ANSI/ASME .

solidworks unfold sheet metal

By far, the most common way to purchase metals for end use is as “sheet metal”, which is defined as a flat metal less than ¼” thick (about 3 gauge) and going all the way down to as thin as 0.0125” (or 30 gauge). Sheet metal can be bent, rolled, formed, stamped, slit, spun and generally fashioned into just . See more

Rolled and welded tube and pipe are by far the most common application for rolled sheet metal, but there are other advantages: 1. Cost: . See more

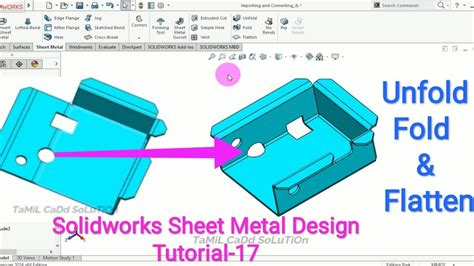

Let’s walk through the steps necessary to flatten a rolled sheet metal part in Solidworks to prepare it for laser cutting. See moreUsing this method means the rolled part features can include holes, edge profiles, or other complex shapes, allowing much faster fabrication, tight fitment without any modification, and no . See more

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, .In this video, I am going to explain about how to create Rolled Sheet Metal & Tubes.I am to explain in detail about below topics,1. Rolled Sheet Metal2. Shee. Learn how to create a SOLIDWORKS rolled component using sheet metal tools so you will be able to unroll/flatten the component if required. SOLIDWORKS designers are always looking for tricks to flatten sheet metal designs within CAD. This gives a few examples of how to do that with a round desig.

solidworks unbend sheet metal

Properties specific to sheet metal parts are calculated and displayed in the Cut-List Properties dialog box. When you assign a custom material to a sheet metal part, you can link the sheet . To roll sheet metal in SolidWorks using the “Sheet Metal Lofted Bend” feature, follow these steps: Create two or more sketch profiles representing the cross-sections of the .To create a sheet metal part from the flattened state: Open a new part. Create a sketch as shown. You do not have to dimension the part. Create a Base-Flange by clicking Base-Flange/Tab or .

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the . Solidworks Animation Tutorial: Simple Metal Roll Forming Process The Tutorial consists of: 1. Parts Design 2. Assembly 3. Animation Note: This is just a model animation of Metal Rolling.Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

Exercise 23 - Cylindrical Sheet Metal parts, Linear sketch patterns

Option would be grayed out in 3D view but when selecting flat pattern it would be active. Purpose of feature: When creating a sheet metal part that contains a bend radius (a radius that is large in size compared to standard tooling radius) that cannot be achieved by standard tooling a technique called bump bend at the press brake is used to . Check out this video to see how to create a rolled component that can be flattened using the Sheet Metal Tool.For more information on SOLIDWORKS products, ch.Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

Thanks for the info man. I'm actually curious more on the rolling with k factor. I've had this question for a long time and it's hard to find a good answer. How do you know what radius to switch to measuring the arc, is it really anything bigger than the MT? The radius on these parts is substantially larger than the MT.Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Creating Drawings of Flat Patterns. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

You can roll back all bends from a sheet metal part in which bends have been inserted so that you can make additions, such as adding a wall. This is available only in sheet metal parts with Flatten-Bends1 and Process-Bends1 features.Select Split (Features toolbar).; In the PropertyManager, under Trim Tools, select the sketch.; Click Cut Part.; Under Resulting Bodies, under , specify the bodies for the split operation.; Optionally, click the callout for each body and save it using the Save As dialog box.

Sheet metal parts in SOLIDWORKS are easy to make thanks to the powerful set of tools, that enable users to model just about everything they can think of. In With over 35 years of experience, the TriMech Group offers a comprehensive range of design, engineering, staffing and manufacturing solutions backed by experience and expertise that is .

solidworks sheet metal pdf

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part .When cuts are made into the flat pattern of a rolled sheet metal cylinder (or semi-cylinder), it is not always easy to extract model dimension data in a SOLIDWORKS drawing. Without proper design intent, detailing the flat pattern positions may not work.26 votes, 23 comments. 76K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. . (a requirement for sheet metal parts). But you need to unfold, add the feature, then fold again. . I had to roll forward, de-select flatten (i must have accidentally clicked it at some point), and roll back. Reply reply . The New F123 Series Printers Makes Carbon Fiber Nylon Parts More Accessible Than Ever Before. . If you need to add fasteners to a rolled sheet metal part in SOLIDWORKS this outlines the correct procedure. You may be familiar with the technique of creating a rolled sheet metal part and then rolling back in the feature tree to show the flat .

You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone). Learn more about SOLIDWORKS, including training options, at https://www.mlc-cad.com/training/solidworks/In this tutorial, Roland demonstrates how to create d. Solidworks Sheet Metal Swept Flange In This Tutorial Of Solidworks Sheet metal we will learn how to use sketched bend and swept flange in Solidworks so watch.If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . There were loads of simple sheet metal parts all over the machine, covering this and that. Our supplier has already been working with us for decades at that point, so all we .

Only parts with exact analytic cylindrical faces can be unfolded. As a test, try to insert an axis on the cylindrical face. If you can insert an axis, the model is an exact cylinder. If you cannot insert an axis, then the model is not an exact cylinder and cannot be unfolded.

Sheet metal PropertyManagers help you create and modify sheet metal parts: Base Flange/Tab. A base flange is the first feature in a new sheet metal part. . You can roll back all bends from a sheet metal part in which bends have been inserted so that you can make additions, such as adding a wall. . SOLIDWORKS welcomes your feedback .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal . This video explores two methods for creating sheet metal cylinders. Innova Systems is an authorised Value Added Reseller for SolidWorks 3D design software. Call us on 01223 200690. http://www.innova-systems.co.uk

Select a linear edge of a planar face on the model to attach the wall to, and click Convert Entities on the Sketch toolbar, or click Tools > Sketch Tools > Convert Entities.; Click .; Drag the vertices near existing bends a small distance away from the bends to allow for the bend radius.Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .HI, Im trying to make a dome shape using the sheet metal forming toom. This is an example of the sort of feature im trying to achieve in solidworks. I have followed the steps using this tutorial to create the forming tool and subsequent shape im after.. The issue that Im now facing is that the forming tool fills in all of the hole punches I have put into place.

solidworks sheet metal examples

8 ft sheet metal brake for sale

Cost Estimators Injection Molding Estimator Machining Estimator Die Casting .

how to roll sheet metal parts in solidworks|solidworks unfold sheet metal